Have you been wondering how you can become a CNC machinist or programmer? With more and more companies using technology to automate things, there is a growing demand for CNC machinists.

In this article we will talk about how to get ready for a job in metalworking. This includes talking about what kind of education you need, what kinds of skills are required, and how much money you can make.

We will also discuss machine fundamentals so that you can make a good decision about your career path.

What is a CNC Machine?

Before learning how to become a CNC machinist or programmer, it is important to understand what these machines are and the role they play in manufacturing.

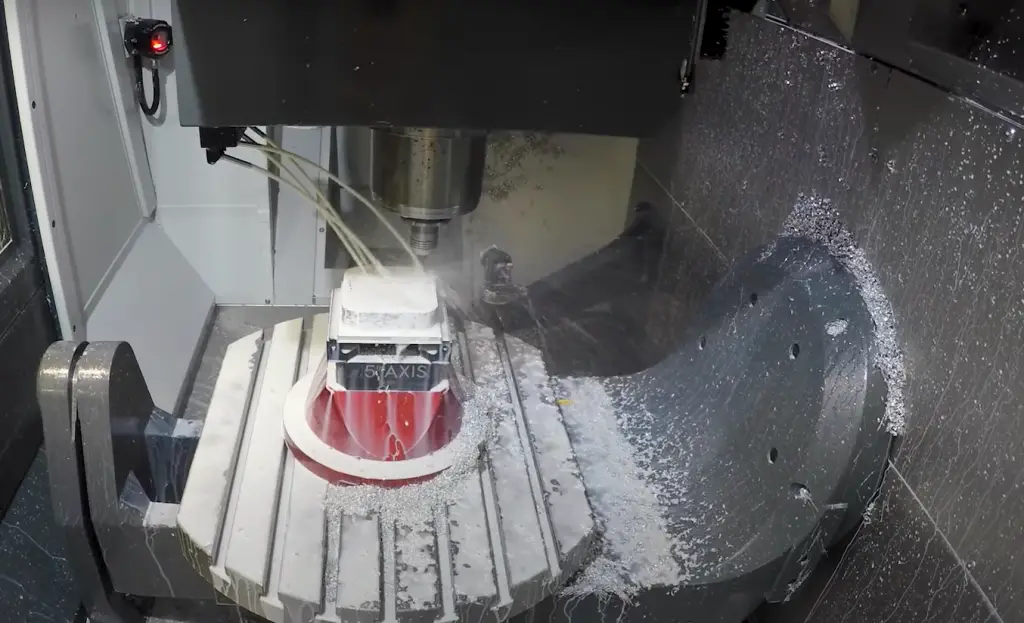

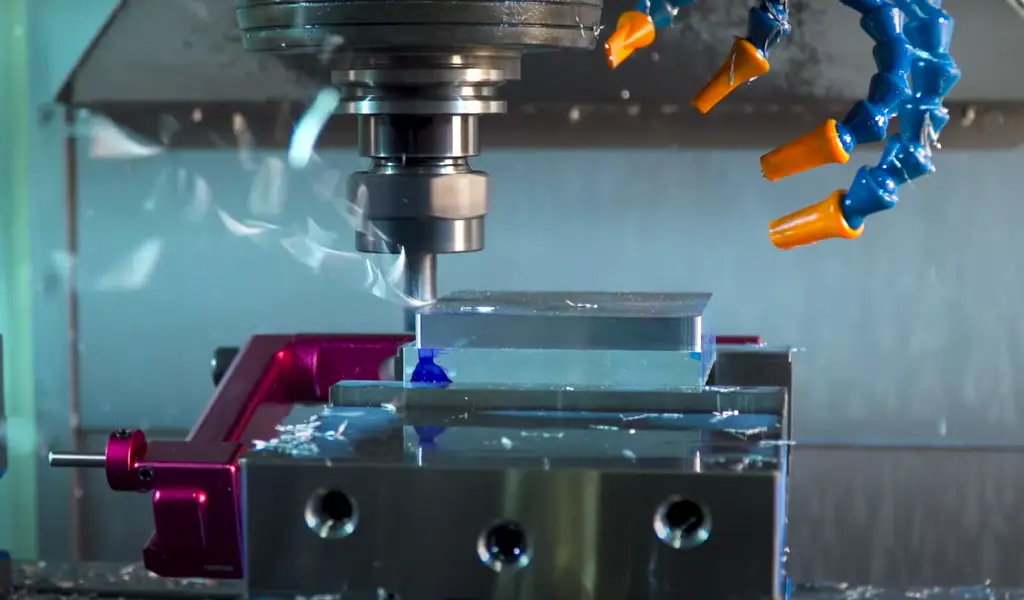

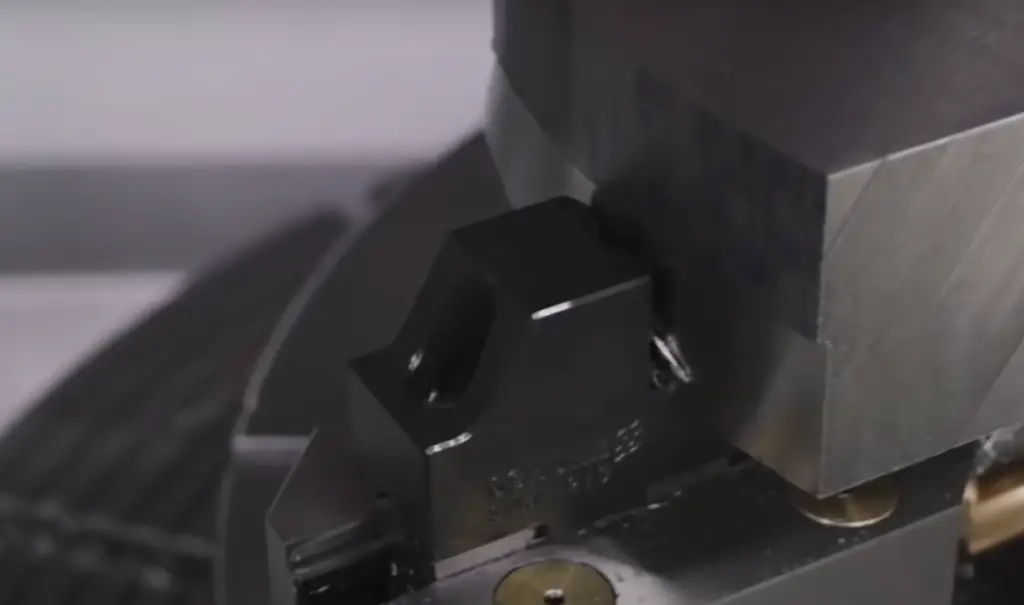

Computer numerical control (CNC) machines are automated tools that can execute pre-programmed commands to create precision components. They use a numerical control language called G-code which describes a set of instructions for the machine to follow.

CNC machines are used by manufacturers who need components that meet specific standards and can be produced quickly. CNC machining is especially useful in areas such as aerospace engineering, automotive manufacturing, medical device manufacturing, and 3D printing. [1]

Education Requirements

To become a CNC machinist or programmer, you need to have at least a high school diploma. You should also try to get some experience working with tools before you apply for the job. If you want to be an expert CNC programmer, you should have a degree in computer science or engineering.

To be a good carpenter, you need to learn about it in school. You also need to be able to follow instructions, read blueprints, use precision measuring tools, and have problem-solving skills. You should also have excellent manual dexterity and hand-eye coordination as well as a good understanding of mathematics.

Skills Required

CNC machinists need to be able to see small details and be comfortable working with computers. They must also know some maths and be able to read blueprints or designs on the computer. They also need to understand the different materials that can be used in machines.

Programmers need to be good at using computers and coding. They also need to know how to fix problems and make their code better.

Programmers should also know about the design of machines that use their programs. This way, they can make sure their programs work well.

Salary

CNC machinists and programmers can earn different salaries depending on how much experience they have and where they work. On average, CNC machinists earn about $54,900 a year.

But if someone has a lot of experience or an advanced degree, they might be able to earn more money.What’s the Difference Between a CNC Machinist and a CNC Programmer?

CNC machinists make the machines work. CNC programmers write code that tells the machine what to do. The programmer is like an artist who makes a painting with code instead of paint. They need to understand math and engineering principles so they can write programs for the machines that work well.

The machinist needs to know how to use and take care of the machines. They need to know how different materials will change when they are machined and what tools work best with those materials.

Machinists often work closely with the programmer so that the machine makes the right parts using the right methods.

How Are These Machines Programmed?

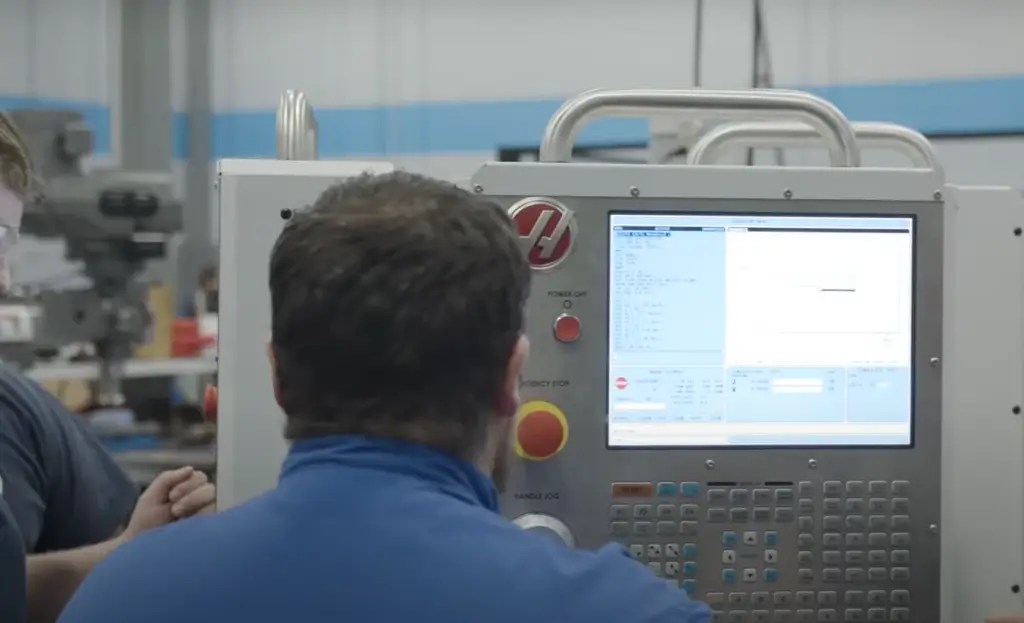

CNC machines are programmed using a numerical control language called G-code. This code tells the machine what to do step by step so that it can make the part or piece of metal. Programmers write this code so that the machine can understand it and follow all of its instructions precisely.

Programmers use computer software to design and program these machines. They can also use CAD (computer-aided design) software to design products that will be made with the machines.

Is Manual CNC Programming Practical?

Yes, CNC machines can be programmed by hand. Some people think it is better to do it this way because they can control it more and it is easier to find and fix problems.

But it can take a lot of time and be boring. Most CNC programming is done with computer software so that the machine can do it by itself and we can check for mistakes before using the machine.

How Hard is CNC Programming?

CNC programming can be hard to learn because it uses a lot of math and engineering. But once you understand these ideas, you can easily change your code.

If you have experience working with computers and other programming languages, that will also help. With enough practice, anyone can become an expert at coding G-code for CNC machines.

What Are the Prerequisites to Become a CNC Programmer or Machinist?

To become a CNC programmer, you need to have some knowledge of mathematical principles and engineering. You also need to know how to use computers and the G-code language.

You can become a CNC machinist by having experience with machines and using tools. You should also be able to read blueprints or designs on the computer.

Knowing about different materials and how they will react when machined is important. You should also know some math and be able to recognize small details.

CNC programmers and machinists need to be patient, focused, and have attention to detail. They also need to be able to work with others and learn new techniques. [1]

What Is a CNC Programmer or CNC Machinist?

A CNC programmer is a person who writes code for CNC machines. These are machines that are controlled by computers. The machines need instructions in a language called G-code to do different tasks.

Programmers have to understand math and engineering principles so they can write the correct code.

They use programs written by programmers to do this. They need to know how different materials will act when machined and which tools work best with those materials.Machinists set up the machines, operate them, and make sure that the machine is making the correct pieces. They also inspect the pieces for accuracy and quality.

How Do You Become a CNC Programmer?

To become a CNC programmer, you will need to be good at math and engineering. You should also know how to use computers, understand the G-code language, and be familiar with computer aided design (CAD) software.

You can become a programmer by taking classes or joining workshops. You might be able to get experience by doing an internship or apprenticeship. Also, it is helpful if you practise writing code on your own at home.

How Do You Become a CNC Machinist?

To become a CNC machinist, you will need to have experience using tools and machines. You should know how different materials act when machined and have an understanding of math. You will also need to be able to read blueprints or designs on the computer.

You can become a CNC machinist by taking classes or joining workshops.

You might be able to do an internship or apprenticeship to get even more experience.What Is the Job Outlook for CNC Programmers and Machinists?

The job outlook for CNC programmers and machinists is good. Companies are always looking for skilled workers who can operate these machines with accuracy and speed.

The demand for CNC programmers and machinists is expected to continue to grow in the future.

How Long Does It Take To Become a CNC Programmer?

It can take anywhere from a few weeks to several years depending on your individual experience and knowledge. There are classes and workshops available that will help you learn the basics of G-code, CAD software, and engineering principles.

Where Can I Learn CNC Programming?

There are many places to learn CNC programming. You can find classes and workshops online or at local trade schools and community colleges.

There are also apprenticeships and internships available that will give you hands-on experience in the field. If you practise writing code on your own, it can help speed up the learning process.

How Can I Become the World’s Best CNC Machinist?

The best way to become the world’s best CNC machinist is by getting a lot of experience. You can get this experience through classes, internships, or apprenticeships.

You should also learn as much as you can about different materials and how they will react when machined. Lastly, practice using the machines and tools you will use in the job. The more you practise, the better machinist you will become.

What Kind of Parts Can I Make as a CNC Machinist?

As a CNC machinist, you can make parts for many different types of products. For example, you can make parts for medical devices, cars, tools, electronics, and aerospace components.

Different materials are used to make these parts.

Additionally, you will need to know which tool works best for each material.How Hard Can CNC Programming Be?

CNC programming can be difficult depending on the complexity of the project. It requires understanding G-code, CAD software, and engineering principles.

Additionally, you need to understand how different materials react when machined and which tools will work best with those materials.[2]

FAQ

Is a CNC machinist a programmer?

No, a CNC machinist is not a programmer. A CNC machinist is the person who operates the machines and tools to create parts from materials. A CNC programmer is the person who writes code that tells the machine what to do.

How Much Does It Cost To Become a CNC Machinist?

It costs money to become a CNC machinist. The cost depends on what kind of classes or workshops you take and how much experience you have.

You will need to pay for courses, books, tools, and materials. Some employers may require that you get certified, which could cost extra money.

Can I Become a CNC Machinist as a Hobby?

Yes, you can become a CNC machinist as a hobby. You will need to take classes or workshops to learn the basics and then practise using the tools and machines on your own.

Practice makes perfect, so the more time you spend practicing with the machines, the better machinist you will become. You can also find CNC machines and materials to use at home.

How hard is it to be a CNC programmer?

CNC programming can be hard depending on the project. You need to understand G-code, CAD software, and engineering principles.

Additionally, you need to understand how materials will react when machined and which tools will work best. Being persistent and having patience is key to mastering CNC programming.

What type of software is used for CNC programming?

CNC programmers use two different types of software: CAM (Computer Aided Manufacturing) and CAD (Computer Aided Design). There are other programs available, but these two are the most popular.

The CAM software converts the design into G-code, which is the language that the machine understands. The CAD software creates a design that can be converted into G-code.

It is important to learn both of these types of software in order to become a CNC programmer.

Is CNC programming a good career?

Yes, being a CNC programmer can be a good career. There is a lot of demand for people with this skill, and it has a promising future. With the right qualifications and experience, you can find job opportunities in many industries.

Additionally, you get to work with cutting-edge technology and create parts for different products which can be both rewarding and exciting.

If you are interested in a career as a CNC programmer, it is important to stay up-to-date with new programming languages and technologies.

Who can do CNC programming?

CNC programming is something that anyone can learn. You need to understand G-code, CAD software, and engineering principles.

Additionally, it is helpful to know how materials will react when machined and which tools work best with those materials. With dedication and hard work, you can become a successful CNC programmer too.

What qualifications do I need to be a CNC programmer?

To become a CNC programmer, you need to understand G-code, CAD software, and engineering principles. Additionally, it is important to understand how different materials react when machined and which tools will work best with those materials.

You may also need certifications in certain types of machines or programming languages. Having experience in the field is also beneficial.

How long is a CNC course?

The length of a CNC course depends on the type of course you take and your experience level. Generally, it can take anywhere from several days to several weeks or even months.

It is important to choose the right course for your needs and abilities so that you get the most out of it.

Additionally, some courses may have a prerequisite before taking them, such as having a certain amount of experience or taking a basic course first. It is important to do research on the courses available so that you can make an informed decision.

What is the salary of a CNC programmer?

The amount of money a CNC programmer earns each year is different for each person. It depends on things like how much experience the person has and where they live. Usually, CNC programmers make about $38,000 per year.

But this can be different depending on the job and location. People who have done this job for a long time might make more money, especially if they know a lot about the work. It is important to look up how much CNC programmers in your area make before taking a job.

How can I find a job as a CNC programmer?

To find a job, you can look online and in your local area. You might also try asking people you know if they know of any open positions.

Additionally, you can go to career fairs and workshops to meet employers. Finally, it is important to keep your skills up-to-date by learning new technologies.

How can I improve my skills as a CNC programmer?

To become an excellent CNC programmer, you should keep up-to-date with new technologies and advancements in the field. You can take classes or do online research and reading to stay on top of the latest developments.

Additionally, it is important to stay organised and pay attention to details when programming. Finally, networking with other CNC programmers can help you improve your skills and stay up-to-date on the most recent trends.

Why should I become a CNC programmer?

Becoming a CNC programmer can be a great opportunity. It is an in-demand skill and there are many job opportunities available.

You will get to work with cutting-edge technology and create parts for different products which can be both rewarding and exciting.

Why is CNC programming important?

CNC programming is important because it allows manufacturers to create parts and products with precision and accuracy. It also helps save time, money, and materials as the production process is streamlined.

Additionally, CNC programming opens up more career opportunities for skilled programmers who can help companies increase their efficiency.

Finally, CNC programming has revolutionized the manufacturing industry by allowing for quicker and more accurate production.

Which industries use CNC programming?

CNC programming is used in many different types of businesses, like making aeroplane parts, cars, medical devices, and things people use every day.

It can also be used for art, like engraving or 3D printing. Plus, lots of robots and machines that work by themselves use CNC programming too.

No matter what business it is, CNC programming is more and more important because it helps production happen faster.

Does CNC programming take a lot of math?

You need to know some types of math, like trigonometry and calculus, to do CNC programming. But you don’t need to be an expert in all forms of math. Basic knowledge can help you understand and program the machines more easily.

Additionally, most CNC programs have built-in calculators and converters which can help you complete calculations quickly and accurately.

Does CNC programming require certification?

No, you don’t need a certification to do CNC programming. But some employers might prefer or require candidates who have certifications in the field.

Additionally, getting certified can show potential employers that you are knowledgeable and experienced in CNC programming which can help you stand out from other applicants.

There are various certifications available, such as the Certified CNC Programmer Certification and the American Manufacturing Technology Certification.

Are there any other skills I need to become a CNC programmer?

In addition to knowing math and being good with technology, it is also important for CNC programmers to be able to communicate well.

This means being able to explain technical concepts in a way that someone without a lot of knowledge about the subject can understand.

It is also helpful to be able to quickly identify and solve problems so that production can run smoothly.

Being organised and detail-oriented is also important when programming CNC machines. Finally, staying up-to-date on the latest trends and technology can help you stay ahead of the curve when it comes to CNC programming.

Are there any online resources for learning CNC programming?

Yes, there are many ways to learn about CNC programming online. You can find courses on websites like Lynda and Udemy that are designed specifically for people who want to get into CNC programming.

Additionally, many universities offer courses that can introduce you to the basics of CNC programming. Finally, YouTube and other websites offer tutorials and videos that can help you further your knowledge of CNC programming.

Can I become a CNC programmer without any experience?

It is possible to become a CNC programmer without having any previous experience. However, it is still important to get formal education or training before beginning your career.

Some employers may prefer candidates who have gone through certification programs. Additionally, there are many online courses and tutorials available that can help you learn the basics of CNC programming.

What kind of job prospects are there for CNC programmers?

CNC programmers have good job prospects, which means there will be more jobs available in the future as technology advances. CNC programming can be used in different industries, like manufacturing and aerospace engineering.

You can also move up to a higher position as you gain more experience. And finally, you could specialise in one area and make more money.

How long does it usually take to become a CNC programmer?

It takes a different amount of time for different people to become a CNC programmer. This is because of things like what they already know and their education.

In general, it takes between 6 months and 2 years to learn enough to start working as a CNC programmer. But if someone has experience with this kind of work already, it will take them less time.

If you know other programming languages, it might take less time to become a CNC programmer. You should have at least 2 years of experience before you try to get a job as a CNC programmer.

Does CNC programming offer good job security?

CNC programming is a good way to get a job that will last. More places are using this technology, so there will be more jobs for people who know how to program CNC machines.

Also, companies are always looking for people who have experience and are willing to work hard. With the right skills, you can get a good job as a CNC programmer.

Do I need to have a college degree to become a CNC programmer?

You do not need a college degree to become a CNC programmer, but it might help you get the job you want. Many employers prefer candidates who have completed some sort of certification program in CNC programming.

Useful Video: How to Become a CNC Machinist

Conclusion

In order to become a CNC Machinist or Programmer, one must have a high school diploma or equivalent, as well as on-the-job training. One also needs to be able to read blueprints and follow instructions carefully.

The ability to use computers is also essential in this career field. With the right education and training, you can pursue a successful career as a CNC Machinist or Programmer.

References:

- https://makeitfrommetal.com/how-to-become-cnc-machinist-programmer/

- https://caminstructor.com/certificatio