Are you wondering if brass will scratch aluminum surfaces? This is an important question to consider when deciding what tools and materials to use for different projects. If the wrong combination of materials are used, it could wreak havoc on your project! In this blog post, we’ll dive into the complex relationship between using brass on aluminized surfaces and explore whether it can be beneficial or harmful to do so. We’ll also discuss some tips and considerations that could help ensure any potential issues are avoided before you begin your work.

What is Aluminum?

Aluminum is the most abundant metal in the Earth’s crust and is found in almost all soils. It is a strong, lightweight, malleable metal with good electrical and thermal conductivity.

Aluminum is one of the few metals that can be recycled without losing its strength or purity. This makes it an attractive material for many manufacturing processes. When combined with other elements, aluminum creates alloys that are even stronger than pure aluminum. The most common alloying element used in combination with aluminum is magnesium.

Aluminum has been used since ancient times for objects such as jewelry and coins. In modern times, the metal has become invaluable for many industries due to its low cost and resistance to corrosion. It is used in products such as aircrafts, automobiles and cookware. Aluminum also has numerous uses in construction, from window frames to roofing materials.

Aluminum is widespread, easy to work with and relatively inexpensive compared to other metals. Its versatility makes it ideal for a variety of applications across many industries and its recyclability ensures that it can be used over and over again without losing any of its properties. With continued innovative use, aluminum will remain an important metal for years to come. [1]

Aluminum has a number of properties that make it an ideal material for many applications:

- Weight. It is approximately one-third the density of steel, making it much lighter and easier to handle. This also makes aluminum more cost-effective than other metals for transporting goods or materials over long distances.

- Low Maintenance. The material does not rust or corrode like other metals do, so it requires very little upkeep and maintenance over time to keep its attractive appearance and performance characteristics intact.

- High Strength-to-Weight Ratio. While it is lightweight, aluminum still provides outstanding strength compared to its weight, making it an excellent choice in structural support applications such as building frames.

- Highly Conductive. The material is a great conductor of electricity, heat and sound, making it ideal for electrical wiring and insulation in some applications.

- Recyclable. As previously mentioned, aluminum can be recycled without losing its strength or purity, creating a near-endless cycle of use cases for the metal. [2]

In short, aluminum offers many desirable qualities that make it a top choice in metalworking and manufacturing processes across multiple industries.

What is Brass?

Brass is an alloy that consists mainly of copper and zinc. It has a golden yellow color, which makes it popular as a decorative metal in jewelry and for making coins or musical instruments. Brass also has some unique properties that make it useful in many applications.

- One of brass’ main advantages is its excellent corrosion resistance due to the protective layer of zinc oxide formed on its surface when exposed to air. This layer helps protect the underlying material from further corrosion.

- Another advantage of brass is its ability to withstand high temperatures without softening or melting, making it ideal for use in valves and fittings for heating systems and other equipment.

- Brass also exhibits good machinability, allowing it to be easily cut, drilled, stamped, shaped, or otherwise worked into the desired finished product.

- In addition to its physical properties, brass also has good acoustic qualities and is often used in musical instruments due to its ability to produce clear tones with a wide range of frequencies.

- It is also electrically conductive and nonmagnetic, making it suitable for many electrical applications. Lastly, brass is relatively inexpensive compared to other metals which makes it a popular choice for many types of projects. All these factors contribute to why Brass maintains its popularity as an alloy metal today. [3]

Why is Brass Used in Work with Aluminum?

Brass is a metal alloy composed of copper and zinc, which makes it incredibly strong and durable. When used in conjunction with aluminum, brass provides a stronger joint than either material could provide on its own.

Additionally, the natural corrosion resistance helps protect components from oxidation and environmental damage when working with aluminum. Furthermore, the low electrical conductivity of brass reduces the risk of galvanic corrosion when using aluminum. Whereas if both metals were to be joined together without any protective coating or alloying agent, they could suffer from accelerated galvanic corrosion due to their differing galvanic potentials. Finally, because brass is relatively inexpensive compared to some other metals, it makes an economical choice for working with aluminum.

Overall, brass is an excellent material choice when working with aluminum due to its strength, durability, malleability, corrosion resistance and cost-effectiveness. It can be used in a variety of applications including machining and fabrication processes as well as joining components together. By combining these two materials, the end result will be stronger than either one could provide on its own.

What Type Of Wire Brush Is Used For Aluminum?

For cleaning and polishing aluminum, a wire brush with soft bristles is recommended. Soft-bristled brushes are much gentler on the metal of aluminum materials and help to avoid scratching and damaging its delicate surface.

This type of brush can also be used in combination with chemical cleaners or abrasive compounds for more thorough cleaning and polishing.Medium-stiff brass wire brush is also a good choice. Soft bristle brushes can be used for light cleaning and finishing work, but they may not remove deep corrosion or oxidation. Stainless steel brushes are too rough and will damage the aluminum surface. Since aluminum is softer than steel, certain types of brass wire brushes are ideal because they won’t cause scratches or gouges like other metal wires. Additionally, using a brass wire brush ensures that any material removed from the aluminum remains soft so as not to contaminate the surface further. [4]

When using a wire brush on any material it’s important to pay attention to the direction of brushing strokes – always running along the lengthwise grain of the metal – to prevent further damage.

What Are Benefits of Using a Brass Wire Brush?

Brass wire brushes are a great tool to have in your arsenal of cleaning solutions, and they offer many benefits. For starters, brass is an incredibly durable and malleable material, allowing the brush bristles to be adjusted for different surfaces. This makes them an ideal choice for rough surfaces or tight spaces that other materials may not be able to reach.

Plus, brass is naturally resistant to corrosion which makes it a great choice when dealing with rust and other corrosive elements. The fact that it’s also non-magnetic means that you won’t run into any problems when using a brass brush around electrical components. The bristles of the brush can also easily drag away dirt and debris.

Brass wire brushes are also incredibly affordable and can be reused many times before needing to be replaced, making them a great choice for people on a budget. They’re also easy to find in most hardware stores or online retailers, so you won’t have to worry about finding the right model for your needs. Finally, brass is highly recyclable, meaning you can do your part in helping the environment by purchasing a reusable brush instead of disposable ones. [5]

Can a Brass Wire Brush Scratch Aluminum?

A brass wire brush can scratch aluminum. This is because the abrasive nature of the bristles on a typical brass wire brush can be enough to cause scratches on softer metals like aluminum. However, it is important to note that this type of damage usually only occurs when the brush is used with significant force or pressure. Furthermore, this type of damage may not be visible right away and may take some time for it to become apparent. [6]

To prevent scratching, it’s best to use a soft bristle brush made from nylon or other materials specifically designed for use with aluminum surfaces. Additionally, using a lubricant such as oil or soapy water helps reduce the friction between the surface and the bristles of the brush. But brass wire brush is suitable for cleaning stubborn deposits of dirt and grime, such as rust, that are hard to remove with other types of brushes.

Factors to Consider Before Using a Brass Wire Brush on Aluminum

Aluminum is a soft and malleable metal, which can be easily scratched and damaged by abrasive tools. Therefore, when using a brass wire brush on aluminum surfaces, it is important to consider the following factors:

- Type of Brush: The type of brush should match the surface being cleaned. A softer brush, like a natural bristle or nylon brush, should be used for light cleaning applications. For more aggressive cleaning tasks or heavily corroded surfaces, a harder wire brush may be needed, such as one made from stainless steel or brass.

- Direction of Scrubbing: Always work in the same direction as the grain of the metal. If the grain runs in two directions, follow both paths. This will help avoid scratching and pitting the metal’s surface.

- Pressure: Apply light pressure to prevent damage to the underlying metal. Avoid pushing too hard as this could cause gouging or permanent scratches.

- Rinsing and Drying: Rinse with water and air dry after use to remove any abrasive particles from the aluminum surface. This is especially important for softer metals like aluminum, which can be easily scratched by dirt and debris left behind by a brass wire brush.

- Protection: Apply a protective coating, such as wax or petroleum jelly, to the cleaned aluminum surface after use. This will help prevent further corrosion or damage from environmental exposure.

Lastly, make sure to always wear protective gear when working with wire brushes. This includes gloves and eye protection to prevent injury from small metal particles that may become airborne during use. [7]

How to Minimize the Risk of Scratching Aluminum with a Brass Wire Brush

The best way to minimize the risk of scratching aluminum is to use caution when using the brush. Always remember that scratches can be created from either direction, so it’s important to keep the side of the brush facing away from the aluminum surface. Additionally, use light pressure and make sure you are brushing in one direction only—not back-and-forth or circular motions.

Additionally, you should consider investing in a softer grade brass wire brush for more delicate surfaces like aluminum. They have shorter and finer wire bristles which provide better control and are less likely to create scratches than stiffer versions. They also allow for deeper cleaning as they do not clog up as quickly as medium or hard grade brushes.

Inspect the aluminum before and after you have used the brass wire brush to ensure that no scratches have been created.

Scratch repairs can be done with a fine-grit sandpaper or polishing compound.So taking these steps will help reduce your risk of scratching aluminum.

FAQs

Is it safe to use a brass brush on aluminum?

No, it is not recommended. A brass brush can cause scratching and damage to aluminum surfaces due to the hardness of the metal. It is best to use a soft bristle brush such as nylon or polypropylene for cleaning aluminum surfaces. If necessary, you can also use a non-metallic scrubbing pad.

Does aluminum scratch easily?

The answer to this question depends on the type of aluminum and the hardness of the material used to scratch it. For example, softer types of aluminum such as 1100 grade and 3003 grade are quite soft and can be easily scratched by a sharp object or even something as simple as your fingernail. Harder grades such as 6061 and 7075 are much more resistant to scratching and may require a harder material such as steel in order to make an impression. However, these grades still are not completely impervious to scratching and will show signs of wear over time with enough force applied. Ultimately, the best way to protect your aluminum from scratches is by taking preventative measures such as powder coating or anodizing, which provide a protective layer that can stand up to more wear and tear. In any case, it is important to remember that aluminum is a relatively soft metal and all types are prone to scratching at some level. Taking the proper preventative measures can help ensure its longevity and keep it looking like new for longer.

Can brass wire brush damage stainless steel?

No, brass wire brushes are generally not recommended for use on stainless steel surfaces because the softer metals in the brush can scratch and damage the surface of stainless steel.

Additionally, brass can leave behind particles that could potentially corrode or otherwise damage the stainless steel finish. It is best to avoid using any type of wire brush on stainless steel surfaces, as it may cause more harm than good. A soft cloth should be used instead to safely clean and polish stainless steel surfaces.

Why use a brass brush?

Brass brushes are a popular choice for cleaning because of their durability and effectiveness. Brass is a strong metal that will not get worn down easily, making it ideal for scrubbing away dirt and debris from surfaces. The bristles on the brush are also able to reach into small nooks and crannies, allowing you to get into all those hard-to-reach places. Plus, brass is resistant to corrosion, so your brush won’t rust over time even if it comes in contact with water or other liquids.

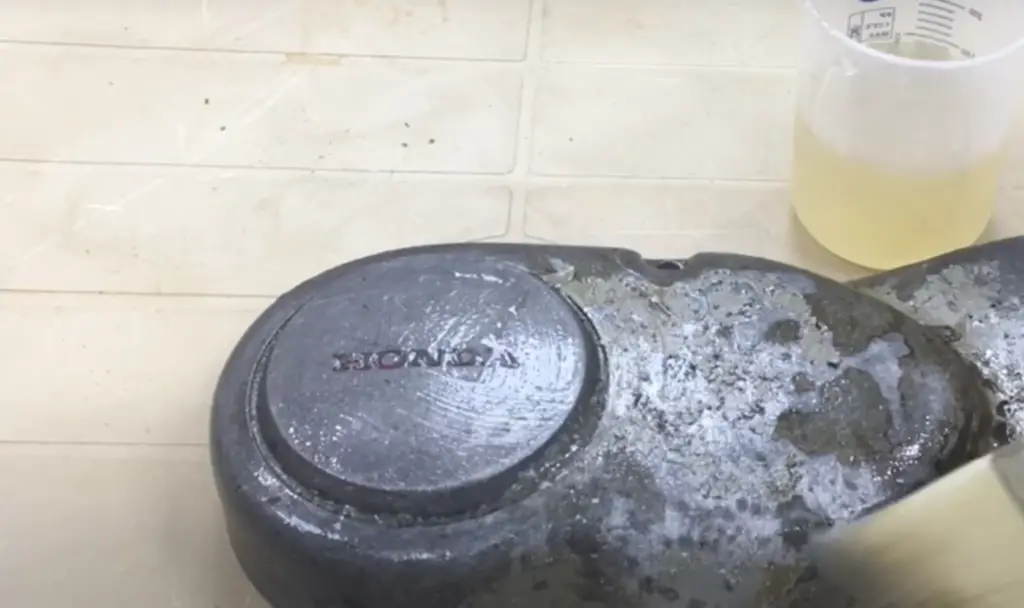

Useful Video: Scratch repair

Bottom Line

Ultimately, the use of brass tools on aluminum surfaces comes down to the individual. How much wear and tear does a particular item see? Are there certain metals that should be avoided altogether? It is important to consider these questions when making any decisions about what should come into contact with aluminum. Before making your decision it is recommended to consult with an experienced professional for a final verdict. Despite the risks, brass tools remain an attractive choice due to their durability and affordability. If you decide that brass is the right fit for your project, make sure to take necessary precautions and use recommended cleaning methods for best protection results.With careful consideration and diligent maintenance of both aluminum and brass products, you can experience mutually beneficial results from the two metals in your next project!

References:

- https://www.aluminiumleader.com/about_aluminium/what_is_aluminum/

- https://www.azom.com/article.aspx?ArticleID=2863

- https://www.thoughtco.com/brass-composition-and-properties-603729

- https://welditmyself.com/wire-brush-for-aluminum/

- https://equip.trade/blogs/diy-tips-tricks/when-to-use-a-brass-wire-brush

- https://weldingtrends.com/wire-brush-scratch-aluminum/

- https://welditmyself.com/wire-brush-for-aluminum/