Have you ever been curious if aluminum, one of the most versatile and omnipresent elements around us, was magnetic? It’s a seemingly simple question with an answer that may surprise you – yes! While it takes quite a bit to get aluminum to magnetize, it is still possible due to its magnetism expression. We will explore why this is the case and discover just how strong of a pull can be obtained from the element in this post. So join us as we explore what makes aluminum surprisingly unique among other metals!

Magnetism And Its Induction

Magnetism is a natural phenomenon that occurs when certain materials are exposed to an external magnetic field. It is also the force of attraction between poles of different magnets. The two main types of magnetism are ferromagnetism, diamagnetism and paramagnetism.

Ferromagnetism

In ferromagnetism, some materials become magnetic when subjected to a strong external magnetic field, while in diamagnetism, certain materials have weak repulsion from an external magnetic field. When a magnet moves near another material, it can induce what is known as an induced magnetic field in that material and cause it to become magnetic or exhibit magnet-like behavior for a short period of time. This phenomenon is known as electromagnetic induction. Electromagnetic induction has many practical applications and is used in a wide variety of everyday technologies, such as electric motors, generators, transformers, and MRI machines.

To understand how electromagnetic induction works, it helps to think about the behavior of a bar magnet placed near an electrical wire. When the bar magnet moves towards or away from the wire, it induces a current in the wire due to a changing magnetic field around it. This current causes electrons in the wire to flow through the circuit resulting in an electric current being produced by the wire. The same principle applies when other magnets and materials are involved: if they move relative to one another, then an induced magnetic field will be created that can cause them to behave like magnets for brief periods of time.

Although electromagnetic induction can be observed in almost any material, its effects are most notable in certain metals such as iron, nickel, and cobalt. These materials are known as ferromagnetic materials and they exhibit the strongest effects of induced magnetism. Other materials such as aluminum, copper, brass, and silver are usually not affected by the presence of a magnetic field.

Electromagnetic induction can be used to create a variety of useful devices including electric motors, generators, transformers, MRI machines, and other applications that rely on magnetic fields. It has become an essential part of our modern world and its importance will only continue to grow in the future. [1]

Diamagnetism

Diamagnetism in turn is a property of certain materials that causes them to be repelled by an external magnetic field, rather than attracted. This type of magnetism is much weaker than ferromagnetism and not as widely used in everyday applications. Nevertheless, it has some interesting properties that can be useful in certain situations. [2]

Paramagnetism

It is the name given to the behavior of certain materials that become weakly attracted to an external magnetic field. This type of magnetism is much weaker than ferromagnetism but can still be useful in some applications, such as detecting small changes in a magnetic field or sensing the presence of other magnets nearby. [3]

What is Aluminum: Key Facts to Know

Aluminum is one of the most abundant elements found in the Earth’s crust. It is lightweight, malleable and strong, making it suitable for a wide range of uses. Aluminum can be recycled easily and quickly with little waste production. As such, aluminum is a popular choice for many products from food and beverage containers to automobiles.

Aluminum has become increasingly popular due to its unique properties. Among them are:

- Highly resistant to corrosion – it does not corrode like other metals when exposed to water or oxygen, making it highly durable over time.

- Lightweight – this makes material ideal for a variety of applications such as cans or building frames where weight reduction is beneficial.

- Versatile – it can be formed into many shapes and sizes with relative ease.

- Recyclable – it can be recycled again and again without losing its properties. This makes it an environmentally friendly choice for most products.

- Low cost – due to the wide availability of aluminum, it tends to be very affordable when compared to other metals. [4]

Aluminum has a wide range of applications, including:

- Transportation – aircrafts, cars, trains and boats all rely on aluminum for structural integrity as well as lightweight performance.

- Construction – it is widely applied in construction due to high strength-to-weight ratio and corrosion resistance. It is used in buildings, bridges, ladders, scaffolding and window frames among other things.

- Packaging – the material is often used to package food, beverages and other products due to its ability to keep contaminants out and maintain freshness for extended periods of time.

- Electrical – aluminum serves as an excellent conductor of electricity, making it a key component in electrical wires, transformers and circuit breakers.

- Consumer Products – it can be found in many everyday items such as bicycles, kitchen utensils, furniture and more.

- Machinery – aluminum’s strength makes it an ideal material for machinery components including engine blocks and gears.

How Magnetic is Aluminum?

Aluminum is not a magnetic metal, meaning that it doesn’t have the ability to be attracted to magnets. This is because aluminum has an unpaired electron in its outermost shell, which prevents it from being affected by external magnetic fields.

However, aluminum can still interact with certain types of magnets in special circumstances.

If an electromagnetic field of great strength is brought near aluminum, it could magnetize the aluminum temporarily, but only until the current is turned off. In general though, aluminum cannot be permanently magnetized like iron or steel.

Despite this, aluminum still displays some magnetic properties. For example, when an alternating current is applied to aluminum it will act as a conductor and create oscillating electric fields which can produce a weak magnetic field that decays rapidly with distance. This type of magnetism is known as induced magnetism, and since it doesn’t involve any permanent magnetization it isn’t very useful for most applications. However, in certain situations such as radio antennas or speakers, the induced magnetism can be used to efficiently generate powerful electromagnetic waves in order to send or receive signals. [5]

Paramagnetic Properties of Aluminum

Aluminum is a highly paramagnetic material, meaning it is strongly attracted to magnetic fields. The presence of unpaired electrons in the metallic structure of aluminum give it its paramagnetic properties. This attractive force can be used to separate aluminum from other materials and make products more pure or less contaminated.

Aluminum has very good electrical conductivity thanks to its relatively low resistance to electric current as well as its high level of paramagnetism. Paramagnetism increases the speed that electrons travel through the metal, allowing electricity to flow more quickly and efficiently across the surface. This makes aluminum a great choice for applications like wiring and electronics components, where reliable electrical conductivity is essential. [6]The paramagnetic properties of aluminum can also be used to measure its thickness and purity. Magnetic fields will increase in strength as the thickness or concentration of aluminum increases, making it possible to accurately measure the amount of aluminum present in a given sample. This process can be applied to both solid and liquid forms of aluminum, making it an effective tool for testing the material’s purity before using it in products or applications.

Magnetic Permeability of Aluminum

Aluminum has a very low magnetic permeability, which is an important factor in many electrical engineering and electronics applications. The low magnetic permeability of aluminum helps to reduce the amount of eddy current losses in inductors and transformers, as well as providing greater control over the flow and direction of magnetic fields.

Aluminum’s low permeability also ensures that other materials used in conjunction with it are more easily magnetized. Additionally, its strength-to-weight ratio makes aluminum an attractive choice for many electronic components that require a durable material but must remain lightweight. [7]

Despite its low magnetic permeability, aluminum can still be used effectively in certain applications where a higher degree of magnetism may be necessary. In such cases, careful consideration must be taken to ensure that the desired magnetic results are achieved. By applying an external magnetic field or coating with a material that increases its permeability, such as iron oxide, aluminum may become more magnetically responsive. Understanding and properly utilizing aluminum’s low magnetic permeability can help engineers to create efficient and cost-effective electronic devices.

Magnetic Susceptibility of Aluminum

Aluminum, due to its high atomic number and metallic nature, has a relatively high magnetic susceptibility. This means that it is highly susceptible to being magnetized in the presence of an external magnetic field. As such, aluminum can be used for numerous applications such as shielding from electromagnetic fields or making electromagnets. It also makes aluminum an excellent conductor of both electricity and heat.

But it can vary depending on its alloy composition. Aluminum alloys with higher silicon content tend to have higher susceptibilities than those with lower levels of silicon content. Additionally, the orientation of the crystal structure also affects the magnitude of the magnetic susceptibility response. Generally, the strongest response is seen in aluminum with a hexagonal crystalline structure.Aluminum’s magnetic susceptibility can be measured using several techniques, with varying degrees of accuracy. These include electron paramagnetic resonance (EPR), magneto-optical Kerr effect (MOKE), and vibrating sample magnetometer (VSM). Each technique has its own advantages and disadvantages but all are effective at measuring the magnetic properties of aluminum. For example, EPR provides the most accurate results but requires a specialist laboratory setup, whereas VSM is much simpler and faster to use but may not be as precise as EPR. [8]

How To Make Aluminum Magnetic?

Making aluminum magnetic is possible through the process of magnetization. This process involves exposing an aluminum alloy to a strong magnetic field, which aligns the atoms and creates a magnetic field within the material. The strength of this field depends on both the alloy composition and intensity of the applied magnetic field. This process must be repeated several times in order to achieve a permanent magnetization, as only some of the atoms are realigned during each cycle.

It is important to note that aluminum alloys may not always respond positively to magnetization processes. As such, it is important to research before attempting any kind of magnetization on your own. Additionally, special tools or equipment may be required for successful magnetization depending on the type and size of the aluminum alloy. If you are unsure about the best way to magnetize your aluminum alloy, it may be beneficial to seek professional assistance from a knowledgeable individual or company.

The process of magnetizing and demagnetizing can be achieved through several different techniques. These are direct current (DC) magnetization, alternating current (AC) magnetization, and pulse magnetization.

In DC magnetization, a direct current is applied to the aluminum, which then causes the electrons to align with the field until it reaches saturation. AC magnetizing involves alternating the direction of the external magnetic field at high frequency in order to cause the electrons’ alignment with each cycle that passes. Finally, pulse magnetizing involves repeatedly applying a high-intensity magnetic field to create molecular magnets in Aluminum’s crystalline structure. [9]

Once magnetization is achieved, however, aluminum alloys can make powerful magnets for many applications. Alnico (an alloy composed primarily of aluminum, nickel and cobalt) in particular is known for its strong magnetic properties and is commonly used in a variety of industries such as electronics, automotive manufacturing and robotics.

Does Anything Stick to Aluminum?

Most magnetic materials such as iron, nickel, and cobalt are attracted to aluminum. However, aluminum is not very easily magnetized itself. When a strong enough magnetic field is applied, it can cause some of the electrons in the aluminum’s atoms to become aligned in one direction. This alignment creates an area where a magnetic force can be generated on the surface of the metal.

Aluminum does not have a significant amount of ferromagnetic material (materials that can retain their own magnetism) present, so it does not hold onto magnets well. It is also non-conductive of electricity which limits its use in electronics or electrical applications.

Although aluminum isn’t highly magnetic on its own, it does have some interesting properties when it comes to magnetism. Aluminum is often used as a shield against electromagnetic fields. The metal’s conductivity works to dissipate the field, meaning that items which are shielded in aluminum will not be affected by an external magnetic force or electric current.

In some applications, such as railroads, magnets can be attached to aluminum frames and then act as a conductor for power throughout a system. This can create a reliable and efficient way of powering equipment without using traditional wiring setups. It also reduces the amount of time needed for installation and maintenance since no extra wiring needs to be done.

Aluminum can also be used in combination with other materials such as electromagnets or permanent magnets to produce various effects.

FAQs

Does a magnet stick to aluminum or steel?

No, the magnet will not stick to aluminum or steel. Aluminum and steel are both non-magnetic metals and therefore do not attract magnets. However, some steel alloys can be slightly magnetic due to traces of other metals in them such as iron. These types of steel may be attracted to a strong enough magnet, but most standard magnets will not have an effect on aluminum or regular steel.

Can aluminum touch metal?

If it doesn’t involve magnetization, then yes. It can touch metal without corroding. Aluminum is a non-ferrous material that does not react to other metals in moist environments. Therefore, it can be safely used in contact with all types of metal without causing any corrosion. However, if the environment is highly acidic or alkaline then there may be some risk of corrosion so it’s best to avoid such conditions when working with aluminum and metal components.

Are most magnets 100% aluminum?

No, most magnets are not 100% aluminum. Magnets can be made from a variety of different materials depending on their purpose and the strength required. Most common types of magnets are made from steel or iron alloys that have been magnetized using electrical current. Some specialized magnets may also include components such as aluminum, copper, or cobalt in order to increase the magnetic field generated by the magnet.

Is aluminum stainless steel magnetic?

No, aluminum is not magnetic. Stainless steel is an alloy of iron and other metals that may contain traces of nickel or chromium which gives it its distinct color and makes it resistant to corrosion. However, due to its composition stainless steel is still magnetic and will attract a magnet if strong enough. Aluminum on the other hand does not contain any ferrous material so it will not be attracted to magnets.

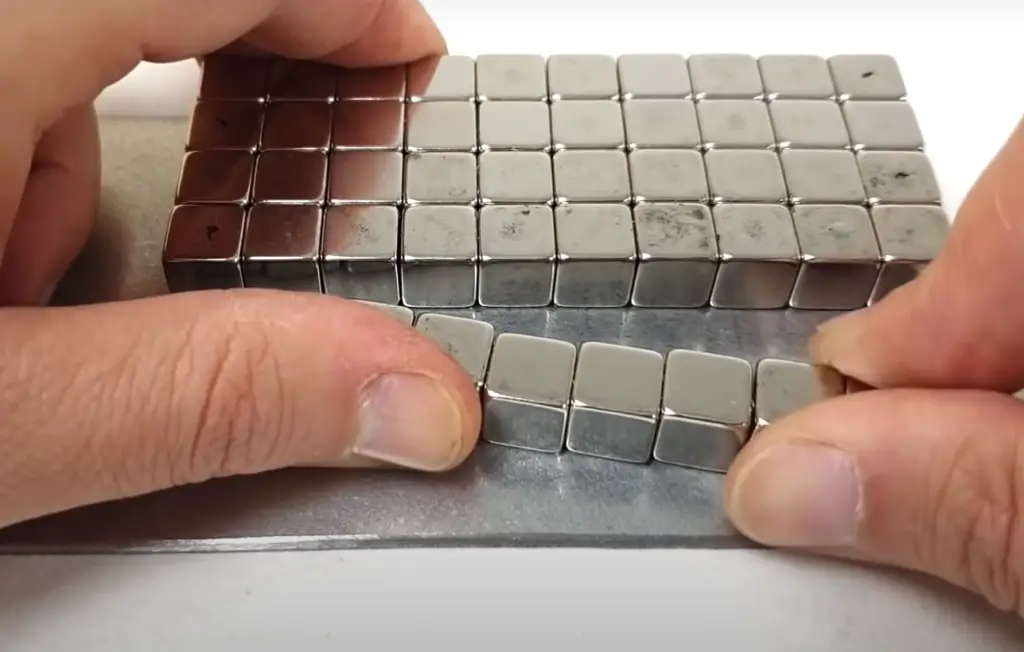

Useful Video: Is Aluminum Magnetic? The Lenz Effect

Final Words

All in all, aluminum is an often overlooked material, but its magnetic properties are extremely interesting. Not only can aluminum be magnetized, it also exhibits other unique properties including its strong ability to retain heat and provide a lightweight solution for many engineering applications. As we have discovered in this blog post, you can easily magnetize aluminum with the right supplies and equipment. It’s important to keep in mind that although the process is possible, it is not as straightforward as magnetizing other materials such as iron or steel. However, safe experiments and creative use of aluminum can help us understand the potential effects of magnetism on various materials.

References:

- https://www.britannica.com/science/ferromagnetism

- https://www.vedantu.com/physics/diamagnetism

- https://www.thoughtco.com/definition-of-paramagnetism-605894

- https://www.livescience.com/28865-aluminum.html

- https://eartheclipse.com/science/misc/is-aluminium-magnetic.html

- https://techiescientist.com/is-aluminum-magnetic/

- https://www.nde-ed.org/Physics/Materials/Physical_Chemical/Permeability.xhtml

- https://lambdageeks.com/is-aluminum-magnetic/

- https://azrust.com/do-magnets-stick-to-aluminum/