Are you looking for a quick and easy way to fix or bond aluminum surfaces? The answer could be JB Weld, one of the best epoxies on the market today. This product has an impressive strength, making it capable of forming strong bonds with various types of materials, including metal surfaces like aluminum. In this blog post, we’ll explore if JB Weld does actually work on aluminum and how you can use it for different applications. From making repairs on auto parts to creating stunning art pieces from aluminum panels – using JB Weld is a great option since it retains its superior performance even when exposed to extreme temperatures or moisture conditions! So let’s dive into this topic and find out more about how JB Weld works on Aluminum!

What Is JB Weld?

JB Weld is an epoxy product that is designed to bond together a variety of materials, such as wood, metal, plastic, and even ceramic. It has become very popular for use in automotive repair due to its versatility and durability. JB Weld can be used to fix holes in radiators, patch holes in exhaust systems, seal cracks in aluminum blocks and create strong bonds between different parts.

When it comes to aluminum specifically, JB Weld can be used just like it would on any other material; however there are some additional considerations you should take into account first. Aluminum behaves differently than many other metals when heated or cooled quickly. When welding aluminum with traditional welding techniques, preheating the material beforehand is usually necessary to prevent it from cracking or warping during the process.

Luckily, JB Weld does not require preheating to be effective. It is also a much simpler and often cheaper alternative to welding aluminum with traditional methods. The epoxy bonds extremely well with aluminum and other metals, creating strong permanent bonds that are more resistant to vibration and environmental elements than many other bonding methods. Additionally, JB Weld can be applied in a thin layer that does not require post-curing like many welding techniques do, further simplifying the repair process. [1]

Will JB Weld Work on Aluminum?

Yes, JB Weld can work on aluminum surfaces. It is a steel-reinforced epoxy adhesive that bonds to aluminum with strong adhesion and superior durability. The epoxy forms a permanent bond between the metal surface and will not break down over time or wear away due to heavy use. This makes it an ideal choice for applications requiring an extremely durable bond such as automotive repairs or construction projects. When properly applied, JB Weld prevents corrosion and won’t shrink when cured, ensuring a long lasting repair. For best results, it’s important to clean the area prior to application and ensure the joint is free of dirt or debris before applying the product.

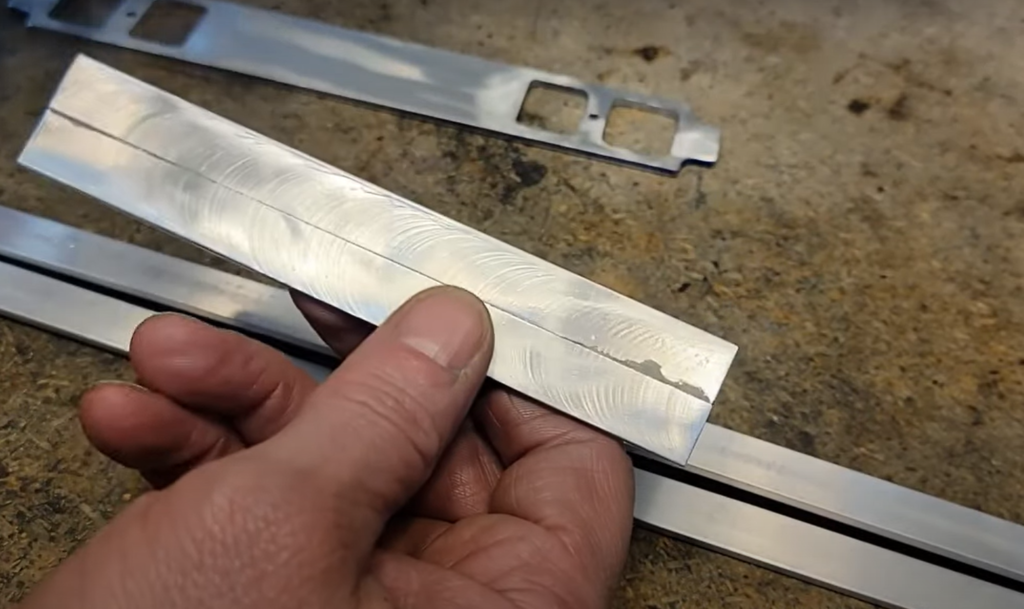

Additionally, roughing up the surface may help ensure maximum adhesion between the two surfaces. JB Weld can also be used to bond aluminum to other materials such as glass, wood, and plastic. It’s important to note that JB Weld will not work on anodized aluminum or any form of aluminum with a painted finish. In these cases, it’s best to use another type of adhesive specifically designed for the material in question.

Overall, JB Weld is an excellent product for making strong repairs on aluminum surfaces due to its high strength and superior durability. With proper preparation and application, you can achieve reliable results that will last for years.

How to Use JB Weld on Aluminum?

Using JB Weld on aluminum can be a great way to get a strong hold and lasting bond. However, before beginning your project, there are some important steps to keep in mind:

- Clean the Aluminum– Before applying JB Weld to aluminum surfaces, it is important to clean off any dirt or debris that may have accumulated on the surface over time. Use a wire brush or sandpaper to ensure the surface is clean and smooth.

- Apply Primer– After cleaning the aluminum, apply an etching primer designed specifically for use with metals like aluminum. This will help create an even stronger bond between the metal and adhesive.

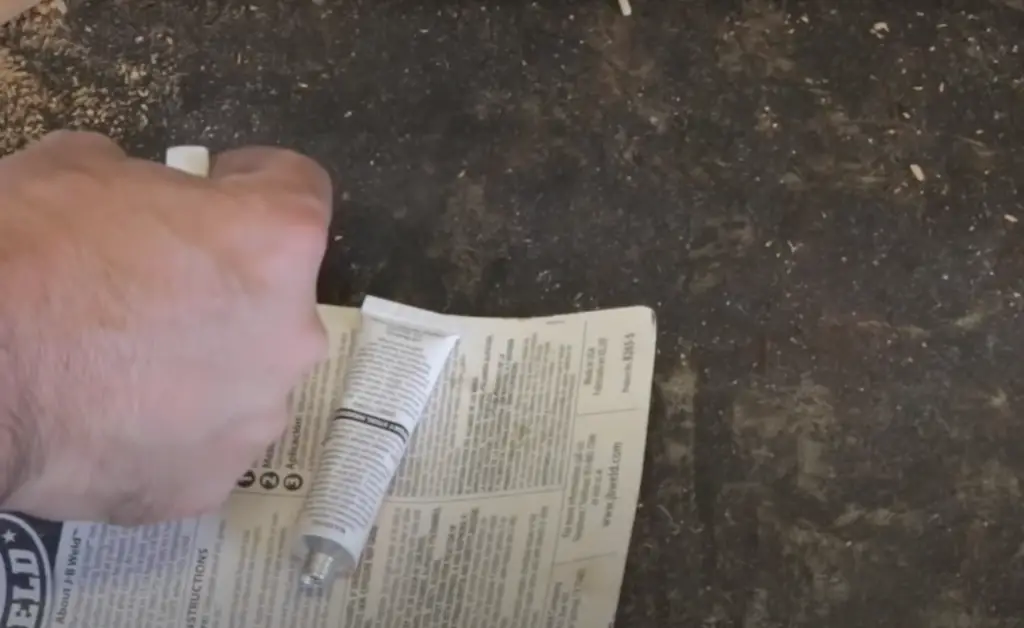

- Mix The Epoxy– In order to activate JB Weld on aluminum, you will need to mix the two-part epoxy together. Follow all directions provided with the product and mix in a well-ventilated area.

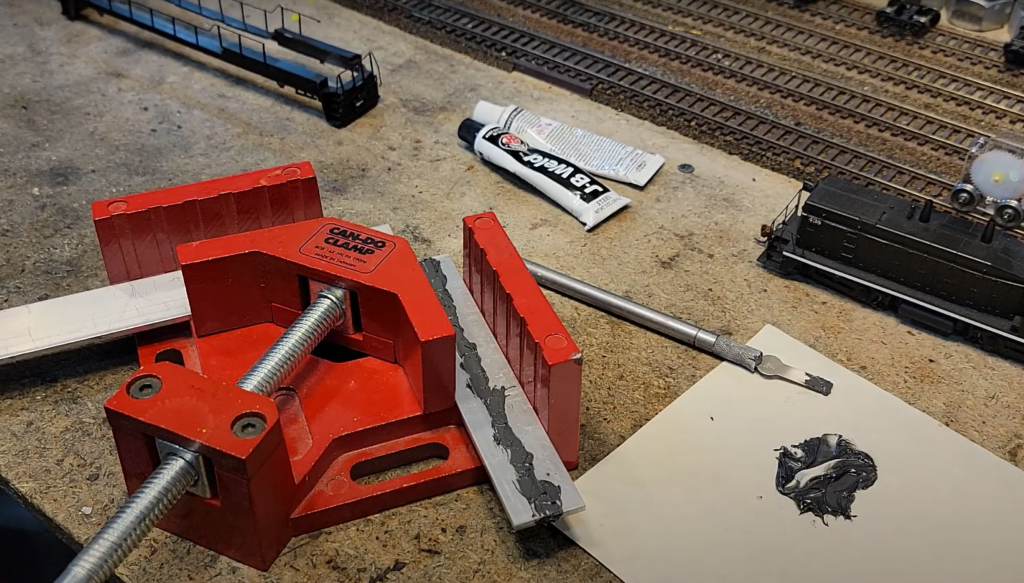

- Apply The Epoxy– Take your time applying JB Weld to the aluminum surfaces and make sure it completely covers them in order to ensure a good bond. If necessary, use clamps to hold the pieces in place while drying.

- Let It Cure– Allow ample time for your JB Weld project on aluminum to cure properly before using or moving it around. This could take anywhere from 3 hours up to 24 hours depending on the size of your project.

By following these steps you can be sure that your JB Weld project on aluminum will be strong and long lasting. This is a great way to get an incredibly durable bond without the use of welding or soldering! [2]

What JB Weld is Best for Aluminum?

JB Weld is best known for its epoxy and adhesive products, but it also produces a specialized aluminum-based product designed for use on aluminum surfaces. This product, called JB Weld Aluminum Repair, is an advanced two part epoxy system that forms a bond stronger than aluminum itself and has the added benefit of being able to resist high temperatures. It can be used to repair small cracks in engines or other large machinery made of aluminum.

Additionally, it can be used to help repair leaking pipes as well as to weld together two pieces of metal without welding equipment.

With proper use and care, this product will provide a long lasting repair that will not corrode or rust like other welding products. This is why it is the preferred choice for a variety of aluminum repairs.When using JB Weld Aluminum Repair, it’s important to be aware that it should not be used on any surfaces that have been treated with an anti-corrosive product. Additionally, as with all adhesive and epoxy products, proper surface preparation is essential for maximizing adhesion and ensuring a successful repair. The surfaces should be clean, dry and free from grease before applying the product. Once applied, the bond will reach full strength in 15-24 hours depending on temperature and humidity levels.

Is JB Weld Strong on Aluminum?

JB Weld is a popular epoxy adhesive used for various applications, including aluminum. It forms an incredibly strong bond on aluminum surfaces and can even be used to repair cracks in metal. Though JB Weld works well on aluminum for most purposes, it’s important to note that it won’t weld two pieces of metal together like traditional welding methods would; instead, the adhesive creates a strong bond between two aluminum objects. This makes JB Weld great for fixing broken pieces or creating new objects with parts attached to each other, but not so great for fabricating something from scratch.

One of the advantages of using JB Weld on aluminum is that it’s relatively easy to use compared to a welding torch and other more complex tools that require special skills and practice. All it takes is mixing the two components of JB Weld together and applying it to the aluminum surface, then allowing the adhesive time to cure. After curing, JB Weld forms a strong bond that will keep your aluminum parts in place for years to come.

Overall, JB Weld is a great option if you need an adhesive on aluminum but don’t have access to welding equipment or the necessary experience. With its strong bonding power, ease of use, and long-lasting reliability, JB Weld can be an effective solution for many projects involving aluminum surfaces. [3]

JB Weld Aluminum Cure Time

When using JB Weld on aluminum, it is important to be mindful of the curing time. After mixing equal parts of the steel-reinforced epoxy adhesive in the provided tube, you will have about 20 minutes of working time before it starts to harden. The full cure can take up to 15 hours at room temperature. For a faster cure (4-6 hours), you can use an oven or heat lamp by placing the bonded aluminum pieces inside and setting the temperature between 200°F and 300°F for 3 hours while checking periodically with a thermometer. Do not exceed 375°F as this may cause thermal shock that would damage your repair job.

Additionally, do not preheat the surface as this may reduce adhesion. JB Weld is best used on clean, dry surfaces so it’s important to remove all grease, oil, dirt and other contaminants before use. With proper preparation and care while applying the epoxy adhesive, you will have a strong bond that can withstand temperatures up to 500°F with good chemical resistance.

JB Weld for a Hole in Aluminum

Aluminum is a widely used metal for many applications, from structural components to automotive body parts. It is also an excellent material for repairing and patching holes, cracks, or damaged surfaces. But when it comes to using JB Weld on aluminum, the answer isn’t as straightforward as some might think.

JB Weld is an epoxy-based adhesive that creates a strong bond between two surfaces. While it can be used on many different types of materials including aluminum, its strength and durability will depend on how well the surface has been prepared beforehand. This includes making sure the surfaces are clean and free from dirt, oil, grease and any other contaminants that could prevent the adhesive from adhering effectively.

Can You J-B Weld Aluminum AC Lines?

JB Weld is a two-part epoxy adhesive that can form strong bonds between most materials, including metal. The manufacturer states that the product has successfully been used on aluminum and cites several examples of applications, such as radiators, water pumps, and AC lines.

However, JB Weld is not recommended for repairing aluminum AC lines because of the extreme heat generated by the system. If you need to make repairs to an AC line, it’s best to use a more specialized product designed specifically for this purpose.

It’s important to note that even if a product successfully adheres to aluminum in one application, it may not be suitable for another job with different parameters. For example, while JB Weld may be able to bond aluminum, the heat generated by an AC line may cause the adhesive to fail.

In addition, using JB Weld on aluminum AC lines is not a good idea because its properties don’t match those of refrigerants and other fluids used in air conditioning systems. The epoxy could react with these substances, leading to dangerous results. [4]

JB Weld Aluminum Radiator?

JB Weld is a two-part epoxy compound that can be used to bond aluminum radiators. It has a strong bond and can be applied in just about any environment, as it doesn’t require extreme heat or pressure. When properly used and following the directions for mixing and application, JB Weld is an effective solution for repairing metal components like aluminum radiators.

Before using JB Weld on an aluminum radiator, make sure the area to be repaired is clean and dry. Any grease, oil, or dirt must be removed first before applying the adhesive. Once the surface area is clean, mix equal parts of the JB Weld compound together according to package instructions until they are thoroughly blended and form a uniform consistency.

Does J-B Weld Work On Aluminum Engine Block?

The answer is yes, J-B Weld can be used on aluminum engine blocks. J-B Weld has an epoxy that will stick to any surface, including aluminum. It creates a strong bond between the parts and seals them together. It is ideal for sealing cracked or broken engine blocks and for repairing stripped threads as well.

All you need is clean rags, protective gloves, a putty knife and a couple of clamps (if needed). Start by making sure all surfaces are clean and dry before applying the product. Mix the two components thoroughly until they become one uniform color then apply it onto the area to be repaired. Use the putty knife to spread it evenly and press firmly if needed.Allow at least 15 minutes of setup time before moving parts around or clamping them down. J-B Weld will create a strong bond that will last for years, as long as the proper application instructions are followed. [5]

How to Sand J-B Weld?

Sanding J-B Weld is not a difficult task, but certain considerations and techniques can help ensure the best results. Before starting to sand, it’s important to make sure that the compound has had ample time to dry and cure. Depending on the ambient temperature and humidity, this can take anywhere from 4-6 hours for thin films of J-B Weld up to several days for thicker applications.

Once the J-B Weld is dry, you can begin sanding. An orbital sander works best since it creates an even finish without gouging too much material away at once. Start with a coarse grade sandpaper (around 120 grit) and work your way up in finer grades (180 – 220) as you go. For a super smooth finish, you can use a polishing compound or buffing wheel. This will bring out the shine of aluminum and leave a professional-looking result.

FAQ

Is J-B Weld strong on aluminum?

Yes, J-B Weld is strong on aluminum. It features a two-part epoxy resin and hardener that form an incredibly strong bond when combined with aluminum surfaces. This powerful adhesive creates a superior bond to other glues, providing repairs that are able to withstand extreme conditions such as heat and moisture. With proper application techniques, it can also be used for building or strengthening aluminum structures. When cured, the adhesive forms a permanent bond that won’t degrade over time due to fatigue or shock, so you can rest assured that your repair will hold up in even the toughest situations.

Is J-B Weld epoxy good for aluminum?

Yes, J-B Weld epoxy is great for aluminum. It’s specially formulated to adhere to and bond with aluminum surfaces, creating a strong and lasting bond that won’t shrink or degrade over time. This allows you to use it in several applications such as filling holes, patching cracks, sealing seams and reinforcing damaged structures. With proper preparation and application techniques, you can be sure that your repair will be able to withstand tough conditions without breaking down or coming undone.

Can I use J-B Weld on my car?

Yes, J-B Weld can be used on your car. It provides a superior bond that will hold up against the extreme temperatures, vibrations and other elements common in cars and other vehicles, making it perfect for repairs and modifications. With proper preparation of the surfaces and application techniques, you can be sure that your repair will be strong and long-lasting.

How long does it take for J-B Weld aluminum to cure?

J-B Weld aluminum typically takes around 8 hours to fully cure, although it may take longer depending on the conditions. To ensure that your repair is as strong as possible, it’s important to allow the adhesive ample time to cure before subjecting it to any stress or shock.

What will J-B Weld not stick to?

J-B Weld is an incredibly strong adhesive, but it is not suitable for all surfaces. It will not bond to polyethylene or polypropylene plastics, Teflon, oil, grease, or wet surfaces. Additionally, J-B Weld should not be used on aluminum that has been treated with any type of heat treatment process such as anodizing. This process creates a surface layer that is resistant to adhesives and welding compounds. For these materials and processes, you will need to use a different bonding solution. It’s important to make sure the surface you are attempting to bond is clean and free of any debris before applying J-B Weld. Otherwise, it may not achieve its full strength potential.

Useful Video: Jb Weld Can Repair Steel – Aluminum – Anything

Conclusion

In conclusion, JB Weld does work on aluminum, but it is best used as a patching material. It should not be relied upon to hold heavy items or parts together in high-stress applications. For these types of jobs, you will need to use an epoxy specifically designed for aluminum that provides superior adhesion and strength. With the proper preparation and application procedures followed, JB Weld can provide a secure and lasting bond on aluminum surfaces.

Once applied correctly, JB Weld offers excellent corrosion protection that will help ensure the bond remains strong over time. So whether you’re looking to make a quick repair or create something new from scratch using aluminum components, JB Weld is an effective choice for joining materials and creating a secure bond.

References:

- https://inboxq.com/jb-weld-for-aluminum/

- https://wisewelders.com/articles/will-jb-weld-work-on-aluminum/

- https://thecampingadvisor.com/does-jb-weld-work-on-aluminum/

- https://www.materialwelding.com/jb-weld-guide-aluminum-plastic-cast-iron/

- http://hullwideworld.com/will-j-b-weld-work-on-an-aluminum-boat/