Do you want to make precise cuts into aluminum but don’t know what tool is best for the job? Plasma cutters provide an incredible way to quickly and accurately cut through metal, and now should be your go-to method when cutting aluminum. If you are looking for a quick guide on how to harness the power of a plasma cutter for your next project involving aluminum, then read on! In this article we’ll explain why it’s so easy to work with aluminum using a plasma cutter, discuss the workflow process associated with setting up the material correctly, and go over all of the safety protocols necessary when working with any type of machinery.

What Is Aluminum and What Kind of Applications Is It Good For?

Aluminum is a type of light metal. It is not heavy and it does not get ruined easily. It can also be shaped and formed into different things. Because of these properties, it is a great choice for many different applications. It can be used in the construction of vehicles, ships, buildings, tools, machinery, furniture, and other items. [1]

Its light weight makes it particularly useful where strength needs to be maximized without adding a lot of extra weight. Aluminum is also very malleable so it can easily be formed into shapes or components for various uses. The most common alloys are 1100, 2011, 2014, 2024, 3003, 5052, 6061, and 7075.

- 1100 – it is used in cookware, chemical equipment, reflectors, and sheet metal;

- 2011 – it has the highest strength to weight ratio of all aluminum alloys. It is great for rivets and screw products;

- 2014 – it is most commonly applied for aircraft fittings, hinge pins, spindles, and gears;

- 2024 – it is very strong alloy that often found in aerospace components such as landing gear pins or airframe components;

- 3003 – it is often used for cooking pans and utensils due to its corrosion resistance properties;

- 5052 – it is suitable alloy for food truck frames, heavy duty mailboxes, boat hulls, canoes and watercraft bodies;

- 6061 – it is great for applications requiring high strength-to-weight ratio, such as aircraft structures, bicycle frames and automotive parts;

- 7075 – it is a good alloy for high-end bicycles and sporting equipment. [2]

Aluminum is also extremely heat resistant, so it can easily be used in a wide range of temperatures. It’s an excellent conductor of electricity, making it a popular choice for electrical wiring applications as well. It is perfect for any kind of motors and generators due to its lack of magnetic properties.

This makes aluminum a great choice for many fabrication projects. [3]Which Cutting Method Is Best For Aluminum?

When it comes to cutting aluminum, there are several different methods that can be used. Each of these offers its own advantages and disadvantages, making it important to choose the best option for your specific needs. The most popular methods include oxy-fuel, laser, and plasma cutting.

- Oxy-fuel cutting is a process that involves using a pressurized gas such as acetylene or propane along with oxygen to create heat which can then be applied to the surface of the material being cut. This method is applied with metals like steel and iron but has limited capability when working with aluminum due to its lower melting temperature. Its main advantages are its affordability and portability. Disadvantages include gas toxicity and potential thermal distortion.

- Laser cutting uses a focused beam of light energy instead of an open flame in order to cut through metal. It is a highly accurate and efficient method that can produce precise cuts with minimal distortion of the material being cut. However, this method can be expensive due to the cost of laser equipment and its high power requirements. The main advantages are its high accuracy and speed.

- Its disadvantages include expense of purchase and maintenance of equipment, as well as safety concerns due to radiation associated with laser beams.

- Plasma cutting is a process that employs an electric arc to heat metal so that it melts and fuses, thereby creating a narrow kerf (width of cut) and allowing the creation of very intricate shapes. Plasma cutting has become increasingly popular because it offers fast, precise, and clean cuts at relatively low cost when compared with other methods. The downside is that it requires more skill than the other two mentioned above since it needs proper setup adjustments in order to function correctly and safely. The key benefits are cost, precision, and speed. [4]

Plasma cutting is probably the best choice because it is fast, accurate, portable, and cost-effective. However, if you need a method that requires less skill or is more suitable for large-scale production jobs then laser cutting might be a better fit. Additionally, oxy-fuel cutting is an option for those on a budget. After all, it will all depend on your specific needs and preferences, so be sure to research all available options before making a decision.

Can Plasma Cut Aluminum?

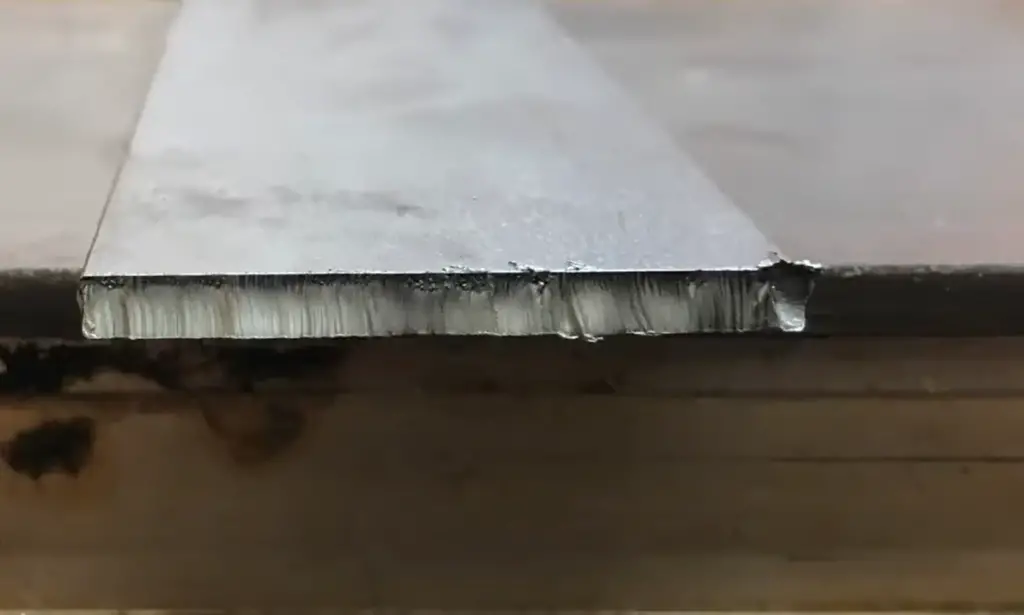

Plasma cutting is an ideal choice for most metals, including aluminum. The process produces clean, straight cuts and does not apply as much heat to the metal as other cutting methods. This reduces warping and burning of the metal. Plasma also works best on thin sheet metals such as those used in aircraft construction or automotive bodies.

It is important to understand that not all plasma cutters are designed for cutting aluminum. Check your product specifications before using it on any type of metal to ensure that it can safely handle the material you want to work with. Also, keep in mind that higher amperage machines will often be able to cut thicker materials than lower amperage ones. [5]

The Basics of Plasma Cutting

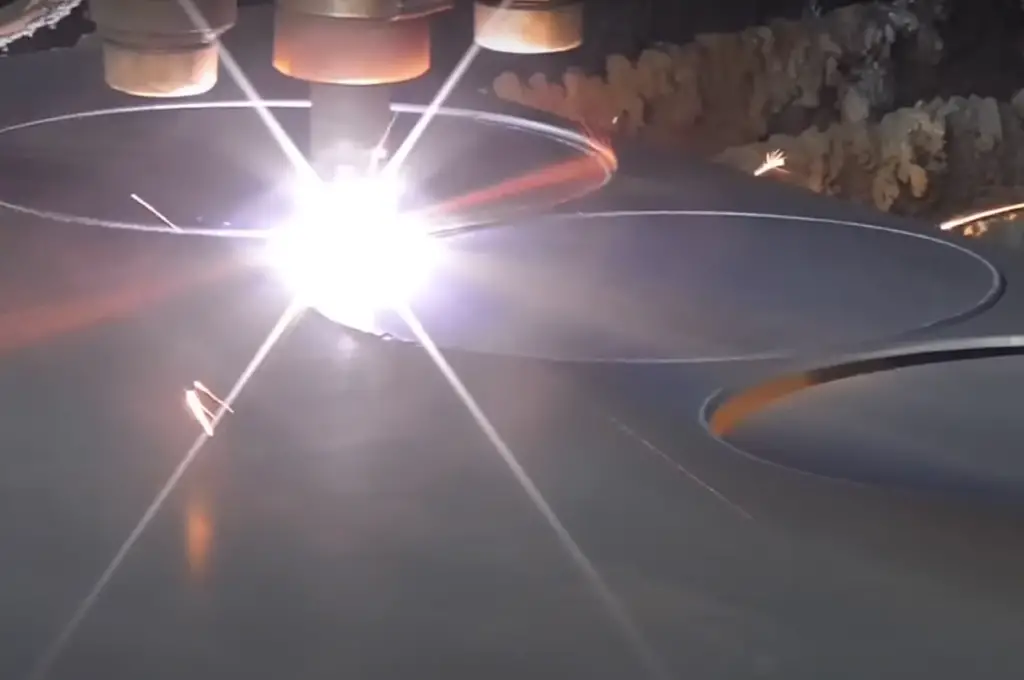

Plasma cutting is a process that uses an accelerated jet of hot plasma to cut through electrically conductive materials. The cutter itself is composed of three main components: an air compressor, a power supply, and a gas source.

To begin the cutting process, electrical current from the power supply passes through two electrodes in the torch head, creating a spark between them. This spark then ionizes the gas inside the torch head, which produces an incredibly hot stream of plasma.

The high temperatures created by this process allow it to easily cut through most metals, including aluminum. Beyond its use as a tool in metal fabrication projects, plasma cutting can also be used for decorative purposes such as creating art pieces or signs made out of metal.

Let’s take a closer look at the process with the following steps:

- Connect the air compressor and power supply to the plasma cutter.

- Set up a metal sheet as the cutting material and secure it in place.

- Adjust the settings of the cutter, including amperage, torch height, arc voltage, gas flow rate, and more. The most common metrics comprise the so-called “cut charts” which specify the recommended settings for different types of materials and thicknesses.

- Once everything is properly set up, turn on the air compressor and power supply to start the plasma stream inside the cutting head of the machine.

- Move the torch along your desired cut line to create your cuts in aluminum or other metals with ease! [6]

With proper setup and operation, you can easily use your plasma cutter – no matter what type of project you are working on.

What are the Benefits of Using a Plasma Cutter?

Plasma cutter applications offer many benefits. Among them are:

- Higher accuracy. The accuracy of the cut is notably improved when compared to other cutting methods. With a plasma cutter, you can make precise and intricate cuts with ease.

- Greater speed. Plasma cutters are very fast. They can easily cut through thick aluminum in a fraction of the time it would take to use other cutting methods such as saws or grinders.

- Lower cost. Plasma cutter process is often more cost effective than other tools for metal fabrication. This is because they require less energy, material, and labor costs.

- Higher quality. The parts created by plasma cutters tend to be of higher quality than those fabricated with other tools.

- Improved safety. As opposed to saws or grinders, plasma cutters are much safer to use. This is because they do not generate as much heat, noise, or dust as other tools, making them far less hazardous to work with.

- Less resources. Not only are they more accurate and faster than traditional methods, but they also require fewer resources and can be used safely without creating too much of a hazard in the workplace. [7]

The best way to ensure you get the desired result is to use quality equipment and accessories, as well as following the recommended safety precautions. This will help to ensure that your projects turn out exactly as planned. With proper care and maintenance, a plasma cutter can be used for multiple projects and continue to offer reliable results.

Is Plasma Cutting Aluminum Dangerous?

For those looking to learn more about how to safely work with a plasma cutter or increase their knowledge of welding and metal fabrication in general, there are numerous resources available online and on social media. Taking the time to become educated on safety protocols and the proper techniques will reward you with a better understanding of how to work safely and effectively.

Suspected hazardous situations that may occur:

- The heat and sparks produced can be dangerous. Sparks can ignite flammable materials nearby, so it’s important to take all necessary precautions when working with a plasma cutter in order to ensure a safe work environment.

- Another hazard is its potential to cause arc flash or burns if you come into contact with the high intensity light that comes from the machine while it is in operation. Proper safety attire, such as protective clothing and goggles, must always be worn before operating any sort of welding tool.

- It is important to remember that aluminum dust can cause respiratory problems if inhaled, so make sure any surrounding areas are well ventilated before attempting to cut metal with a plasma cutter.

- One more hazardous situation is the risk of electric shock. Plasma cutters can potentially cause electrical shocks if not properly grounded, or if there are any faulty components in the machine itself. Make sure to check the power source before plugging it in and be sure to use an extension cord with proper grounding when necessary. [8]

Top 5 Mistakes When Plasma Cutting Aluminium Worth Avoiding

Avoiding these common mistakes will help ensure successful aluminum plasma cutting every time. So read on soon.

- Incorrect plasma cutter setup – It’s essential to have the correct settings to get the best cut on aluminum. Setting the speed too high or using a lower amperage than recommended can cause burning and other damage that can ruin the material you’re cutting.

- Not using the proper size output nozzle – If you use a nozzle size that is too small for the job at hand, it will reduce the flow of gas through the plasma torch and decrease cutting speeds as well as weaken your edge finish quality. Use a larger nozzle size if necessary for faster speeds and clean cuts with minimal splatter.

- Improper torch height adjustment – This is one of the most common mistakes when cutting aluminum. Adjusting the torch height too close or too far away from the material can cause poor cut quality, more spatter, and slower speeds. A consistent height should be maintained while moving the torch along the material.

- Not securing the material properly – It’s important to secure it firmly in place so that it doesn’t move during the process. This is especially important if you’re dealing with thicker materials since they can warp from heat and cause a mis-cut.

- Using the wrong torch speed setting – Another common mistake when plasma cutting aluminum is using an incorrect speed setting on your torch. If you set it too low, you’ll get burned or worse yet, no cut at all. On the other hand, if you set it too high, you’ll get an uneven cut and a lot of debris build-up. It’s best to run some test cuts at various speeds before settling on the optimal setting for your project. [9]

Safety Instructions for Working with a Plasma-Cutting Machine

Remember the following safety instructions:

- Wear necessary protective equipment such as goggles, face shield, gloves, and hearing protection when working with a plasma cutter.

- Make sure that all work surfaces are free of debris or any flammable materials before beginning cutting operations.

- Keep an eye on your surroundings and make sure the room is adequately ventilated to prevent gas accumulation.

- Connect the grounding clamp securely to prevent electric shock.

- Set the current flow on your plasma cutter to match the type of material being cut (aluminum).

- Ensure that power settings are appropriate for the material being cut and that the nozzle and electrode tips are in good condition.

- Keep your body away from any sparks created during the cutting process.

- Never operate a plasma cutter near combustible gas or liquids, as they can ignite when exposed to the high temperatures of a plasma arc.

- Turn off power to the machine before changing electrodes or nozzles.

- Always turn off power and disconnect the cutting machine from the power source before leaving the work area or making repairs on equipment. [10]

Make sure to shut off the power source and disconnect the machine before cleaning or making repairs.Always check for any loose connections or damaged components before use.

These safety instructions should be followed when working with a plasma cutting machine to ensure maximum safety while cutting aluminum with a plasma cutter. Following these tips will help you stay safe, maximize your productivity, and make the most of your plasma-cutting experience.

How To Choose the Right Plasma Cutting For Aluminum Parts?

The plasma cutter is one of the most versatile tools when it comes to cutting aluminum parts. But not all plasma cutters are created equal. When choosing a plasma cutter, there are several factors to consider in order to get the best results for your aluminum parts.

First, you need to select a power range that will be suitable for cutting through aluminum.

You may need higher amp ratings if you’re working on thicker materials or larger and more complex shapes.Make sure you use a machine specifically designed for cutting metal like aluminum, as some machines are only suited for thin sheet metals like steel or stainless steel. Next, you’ll want to think about the cutting speed of your plasma cutter. The faster the machine is able to cut through aluminum parts, the more efficient and productive you can be in the workshop.

Look for a plasma cutter with adjustable speed settings or consider using an air compressor as part of your setup if you need more power and control over the cutting process. [11]

Finally, consider any extra accessories that are necessary when working with aluminum parts. You may need special tips or nozzle designs depending on what type of aluminum pieces you’re working with. Be sure to select a compatible machine that can use these accessories for optimal results.

What Aluminum Alloy is Not Suitable for Cutting?

Since aluminum has a strong affinity for oxygen, some alloys of aluminum can oxidize rapidly when exposed to the heat generated by plasma cutting. As a result, certain aluminum alloys are not recommended for use with a plasma cutter.

These include:

- 7000 series (zinc-magnesium and zinc-magnesium-copper), which are susceptible to rapid oxidation and pitting;

- 2000 series (copper-containing) alloy that often contains high levels of silicon, which can cause porosity in cut edges;

- 5000 series (magnesium-based) alloy, which is also prone to oxidation;

- 6000 series (magnesium-silicon), which has low thermal conductivity and requires extra process control.

For most projects involving aluminum sheeting or thin plates, the best option is to use an alloy from the 1000 series or an aluminum-copper blend. These alloys are less prone to oxidation and can be cut with a plasma cutter without sacrificing quality.

Plasma Cutting Vs Laser Cutting – What’s Best For The Job?

Working with a plasma cutter is an effective way to produce accurate, precise cuts. Whether working for industrial or hobbyist purposes, plasma cutting can be used on many types of metals including steel and stainless steel. However, when it comes to cutting aluminum, there are other options available that may be more suitable for the job.

Laser cutters are one such technology that provide more efficient and accurate results than plasma in certain situations. Let’s explore the differences between these two methods in detail.

- Speed aspect: When cutting thinner gauges of aluminum sheets (up to 1/4 of an inch), a laser cutter will generally produce faster results compared to a plasma cutter due to its higher power levels and narrower beam widths. This means that with a laser, you can make multiple cuts in a fraction of the time it would take to do so using plasma.

- Precision aspect: A laser cutter is typically more precise than a plasma cutter due to its smaller beam and higher power capabilities, making it better suited for intricate projects or tight tolerances. Its concentrated beam ensures that even small shapes can be cut accurately and precisely every time.

- Cost aspect: Laser cutting is usually more expensive per hour than plasma cutting due to its specialized equipment and personnel requirements.

- Versatility aspect: Plasma cutters are incredibly versatile and can be used on many types of metal including steel, stainless steel, brass, copper, aluminum alloys, and other non-ferrous metals. However, when it comes to working with aluminum specifically, a laser cutter will generally produce better results. [12]

It is essential to conduct thorough research and carefully weigh the options before making a decision that fits your project requirements. Both plasma cutting and laser cutting have different advantages and disadvantages that should be taken into account when deciding which method to use. Doing so will help ensure that you get the best possible outcome in terms of quality, speed, precision, cost-effectiveness, and overall versatility.

FAQs

How many amps does it take to cut aluminum with plasma?

The amount of amps it takes to cut aluminum with plasma depends on the type and thickness of the material being used. Generally, thinner materials will require less amperage than thicker ones.

In some cases, it can take anywhere from 25-100 amps. For thicker pieces, you may need to use a machine that operates at higher amperage. It is important to make sure that your plasma cutter’s capacity matches up with the material you are using before trying to cut it.

How thick can a plasma cutter cut aluminum?

The answer to this question depends on the type of plasma cutter you are using. Generally, a standard plasma cutter can cut aluminum up to 1/4 inch thick. However, if you are using an industrial-grade plasma cutter, it may be able to cut thicker materials such as 3/8 inch or even 1/2 inch aluminum plates. The cutting efficiency also varies depending on the current settings and consumables used. For instance, low amperage and high pressure will result in faster cuts but lower quality than high amperage and low pressure.

What gas do you use to plasma cut aluminum?

It is recommended to use compressed air as the gas.

It has a higher heat capacity than other common gas (such as nitrogen and argon) which helps prevent warping of the metal while maintaining high cut quality. It also reduces cost and complexity since an oxygen concentrator isn’t needed.

What metals can not be cut with a plasma cutter?

Non-conductive materials, such as wood and plastic, cannot be cut with a plasma cutter. Metals that are not electrically conductive, like stainless steel or titanium, also cannot be cut with a plasma cutter. Furthermore, certain aluminum alloys contain particles which may generate hazardous fumes when cut with a plasma cutter. Therefore, these alloys should not be cut using this tool.

Useful Video: Cutting Aluminum with Plasma Cutter

Let’s Summarize

The plasma cutting is not something to be taken lightly. It requires specific precautions and procedures in order to be used properly. However, when done correctly, it can be an efficient, precise process which yields excellent results. It is mainly used for work that requires intricate pieces that require high accuracy levels such as weld preparation or automotive parts production. With the right know-how and practice, plasma cutting becomes a simple task with amazing results. So why wait? Take the initiative today and start exploring the world of plasma cutting!

References:

- https://blog.thepipingmart.com/metals/aluminium-vs-aluminium-alloy-whats-the-difference/

- https://www.kloecknermetals.com/blog/a-guide-to-the-most-popular-all-purpose-aluminum-alloys/

- https://www.weerg.com/guides/aluminum-properties-and-advantages-of-aluminum

- http://blog.thermacut.net/en/all-news/laser-plasma-or-oxy-fuel.html

- https://espritautomation.com/plasma-cutting-aluminium/

- https://www.rapiddirect.com/blog/can-plasma-cut-aluminum/

- https://tampasteel.com/what-is-plasma-cutting/

- https://www.gizmoplans.com/what-are-the-hazards-of-cutting-aluminum-with-plasma/

- https://www.westermans.com/blog/dont-make-these-3-mistakes-when-plasma-cutting-aluminium/

- https://esab.com/us/nam_en/esab-university/blogs/maintenance-of-plasma-cutting-machine-a-step-by-step-guide/

- https://americantorchtip.com/blog/how-to-choose-plasma-cutter/

- https://www.tymetal.com/laser-cutting-vs-plasma-cutting/