Are you looking for the most convenient way to cut aluminum pieces and panels? A miter saw can become your perfect companion when it comes to this kind of metal work. With its adjustable blades, straight-line guide, and necessary safety measures in place, a miter saw is capable of cutting neat lines on different types of materials – including aluminum!

In this blog post, we’ll dive deep into how exactly a miter saw works for aluminum cutting – from scratch to finish. You’ll learn tips and tricks that will help make sure your aluminum projects come off without a hitch. So let’s get started!

Expert Advice on Cutting Aluminum

Milling

A milling machine is the best tool for the job. This process uses rotating cutters to remove material and create a precision cut. To get started with using a milling machine, you’ll need to choose the right type of end mill cutter for your project as well as select the correct speed and feed rate. It’s also important to be mindful of chips and debris that may fly out during this process.

Sawing

If you don’t have access to a milling machine, sawing can be an effective way to cut aluminum plates or rods into smaller pieces. For larger projects or thicker material, you’ll want to use a bandsaw.

It’s important to use the right type of blade and have it sharpened regularly in order to get the best results. You should also use a cutting lubricant or coolant when sawing as this will help reduce friction and prevent heat buildup.

Shearing

When you need to cut straight lines into thin pieces of aluminum, shearing is an ideal method. This process involves using two blades that come together to create clean cuts with minimal waste. To get started, you’ll need a pair of shear blades as well as an adjustable fence for accurate placement of your workpiece.

Water Jet Cutting

Waterjet cutting is a great way to cut through any type of aluminum without having to worry about heat buildup. This process uses a high-pressure stream of water combined with an abrasive material such as garnet or aluminum oxide to cut the metal. You can control the size and shape of your cuts by adjusting the pressure and feed rate, making it ideal for more intricate projects.

What Tools to Select for Cutting Aluminum?

There are a variety of tools and methods available. Some of the most common include saws, shears, routers, laser cutters, plasma torches, and water jets. Each method has its own advantages and disadvantages so it is important to choose the right tool for your project.

Saws

These are one of the oldest methods used for cutting aluminum but they remain popular today due to their affordability and ease of use. Traditional hand saws can be used for straight cuts while circular saws can make curved cuts with greater accuracy. Many people prefer band saws as they can make both straight and curved cuts with greater precision than other types of saws.

Shears

They are often used to cut sheet metals and other thin materials like aluminum. They come in a variety of sizes and shapes, allowing for detailed cuts with less waste. Like saws, they can be manual or powered to increase efficiency.

Routers

These are versatile tools that can make intricate cuts on many different materials, including aluminum. They allow users to create complex shapes with precision and accuracy. Some routers even have the ability to adjust the cutting speed for smoother edges and better results.

Laser Cutters

These tools use an intense beam of light directed through a focusing lens or mirror onto the material which is melted away as it is cut into shape.

This method offers precise results with minimal heat-affected zones. Laser cutters are typically more expensive than other methods, but can be worth the investment for complex projects.

Plasma Torches

Here is a little bit of another principle. The instrument applies a gas mixture that is heated to extreme temperatures and then forced through a small nozzle. This superheated gas melts the aluminum as it is cut into shape. The plasma torches offer fast cutting with little heat affected zone while requiring minimal effort from the user.

Water Jets

These tools use high-pressure streams of water and abrasive particles to cut materials like aluminum with great accuracy. This method produces clean cuts with no heat-affected zones and minimal waste material. However, water jets can be costly to operate due to their energy requirements and need for specialized equipment.

Miter Saw

Aluminum trim and edging can be easily cut using them. They offer precise cuts with minimal effort from the user, making them one of the most popular tools for this purpose. [1]

Working Principles of the Miter Saw

Miter saws operate by means of a rotating arm that holds the saw blade in place. The arm is connected to a motor, and when it spins, the saw blade rotates at an angle relative to its holder. This angle allows for precise cuts in wood or other materials. [2]

The miter saw also has a work table which supports the material being cut. This table can be adjusted to accommodate different angles and widths of materials. As the blade moves across the table, it creates a cut along with desired length and angle.

These tools are designed with safety features such as guards which cover the cutting area from top to bottom and side-to-side, so that operators do not come into contact with the blade. There are also built-in dust collection systems which help keep the cutting area and working environment clean and safe. [3]

Adjustable settings on a miter saw allow for repeatable cuts of identical angles, lengths, widths, or depths in a material. This ensures accuracy when joining two pieces of wood together. Other features such as laser guides make it even easier to replicate previous cuts over again with precision.

Miter saws come in various sizes and models designed for specific tasks like crosscutting, beveling, mitering and compound cutting. They can also be used for other applications like sanding, routing, marking and drilling depending on the accessories attached to them. [4]

What Are the Features and Possibilities of a Miter Saw?

A miter saw is a versatile tool that can be used for making accurate crosscuts, miters, and angled cuts in wood. It is an essential tool for any woodworking project, whether it be building furniture or trimming out a window frame.

Miter saws are designed with precision-machined parts that make it easy to adjust the blade angle for precise cutting results. This makes them ideal for cutting at precise angles and lengths, which can be difficult to achieve with hand tools such as a handsaw or coping saw.

Some models even include special features such as sliding blade mechanisms and laser guides for more accurate cutting.Miter saws can also be used to make quick and precise cuts in a variety of materials, including wood, plastic, aluminum, and even steel. Many models feature adjustable speed settings so you can customize your cutting speeds according to the material you are working with. Some miter saws also come with dust collection systems to help keep the work area clean.

It also performs the broaching function. Broaching is a process of cutting or forming shapes in metal parts. It requires a specialized tool called a broach, which is usually mounted on the miter saw itself. The broach cuts into the material at an angle, creating a variety of shapes and sizes depending on the project.

Another awesome thing is that there’s a laser. It’s a great feature for a miter saw because it makes it easier to make accurate and precise cuts. The laser projects the exact line of cut across the material, making sure that all your cuts are aligned perfectly.

Miter saws can handle a variety of tasks with ease and precision. Whether you’re cutting large boards or small trim pieces, there is a miter saw that will fit your needs. With their adjustable settings, laser guides, and specialized features, these tools can help you produce professional-looking results in no time at all. [5]

Advantages of Applying a Miter Saw

A miter saw is one of the most efficient and accurate ways to cut wood. With a range of features, these tools offer many benefits when it comes to cutting wood.

One major advantage is accuracy.

This makes it easier to create high-quality projects that look professional and aesthetically pleasing. [6]Another benefit is its speed. These tools allow you to quickly make multiple cuts in just minutes, saving time and effort on projects such as door frames or picture frames where angled cuts are necessary. The dust collection system helps reduce cleanup time after cutting pieces.

After all, miter saws are relatively safe tools when used correctly. With the built-in guards and safety features, it is much less likely for an operator to suffer from injury or damage. These powerful yet precise tools can produce excellent results in no time at all! [7]

In What Spheres Apply A Tool?

It is a versatile power tool that can be used for cutting different types of materials such as wood, metal, plastic, and other materials. It’s commonly used in carpentry and woodworking projects to make precise angled cuts.

Miter saws are also frequently used in the construction industry for making accurate trim cuts on windows and door frames. It’s also great for making picture frames and intricate molding cutouts.

In addition to being great for cutting large pieces of lumber into smaller parts or making precise angles, miter saws can also be used to drill holes through thick materials like plywood.

If you’re looking to tackle any type of DIY project that requires cutting or drilling material, then a miter saw should be the first tool to consider. This powerful and versatile tool makes quick work of any job. With the right blade, you’ll be able to cut through thick materials with ease and accuracy. Give it a try and see just how much of an impact it can have on your projects. [8]

What to Keep in Mind When Picking a Miter Saw?

When it comes to picking the right equipment for your needs, there are several factors to focus on.

- The first is the size of the saw and what type of projects you plan on doing with it. If you are planning on using a miter saw for crown molding or trimming long boards, then you will want to go with a larger saw that has more power and higher RPMs than a smaller saw.

- You also need to think about what kind of features you need in a miter saw. Some popular options include laser guides, dust collection systems, adjustable angles and speeds, and soft start motors. Each of these features can add convenience and accuracy when cutting different materials.

- Remember about safety. Always wear protective gear, such as gloves and eye protection, and make sure the saw is properly secured to a stable surface before use. Make sure you read up on the proper techniques for making precise cuts with a miter saw so that you can avoid any unnecessary accidents.

- Another factor to consider when picking out a miter saw is the price range. It’s important to invest in a quality tool so that it will last longer and perform better – but don’t forget that there are also more budget friendly options available too! Do some research ahead of time and shop around for the best deal on your new saw.

Is Aluminum Good for Cutting with a Miter Saw?

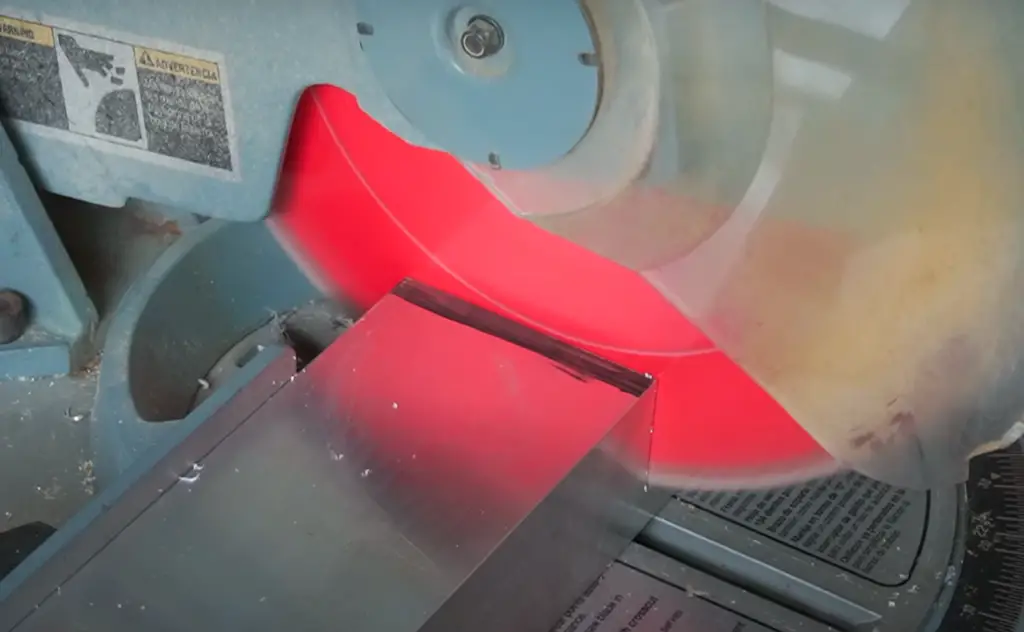

Aluminum can be cut with a miter saw, though it does require a few additional precautions. First, you should use a special miter blade that is specifically designed for cutting metals like aluminum.

You should also use cutting oil or wax as a lubricant when making cuts with your saw. To avoid warping or melting of the metal during cutting, follow these steps to decrease friction and heat build-up.

With the proper safety precautions in place, aluminum can be effectively cut with a miter saw. [9]Additionally, you should also use a clamp to secure the metal in place while making cuts with your saw. This will prevent it from shifting or slipping during the cutting process, resulting in more accurate results.

Remember to check your cuts for any rough edges that may need to be smoothed out before installing or using further. Following these tips can help you safely cut aluminum.

What Blades Are Required for Cutting Aluminum With A Miter Saw?

The necessary blade type will depend on what kind of aluminum you are working with. If you are working with soft or thin aluminum, then a standard 10-inch carbide tipped blade should be sufficient.

However, if you are dealing with thicker or harder aluminum, then a metal cutting blade may be necessary in order to get the job done right. It is also important to make sure that your miter saw has enough power and torque to handle the material thickness that you are dealing with. For cutting metal materials, it is advisable to use a slower feed rate to achieve optimal results. This will help ensure accuracy and reduce any chance of burning or warping the material during the cutting process. [10]

Step-by-Step Instruction for Cutting Aluminum

- Gather the materials. A miter saw, aluminum stock, protective equipment and any clamps you might need to secure the material while cutting.

- Set up your workspace by making sure that the miter saw is on a stable surface and all other items are within easy reach.

- Put on safety goggles and gloves to protect yourself from flying debris or sharp edges during cutting.

- Measure the size of the cut you need and mark it with a pencil or marker on the aluminum stock.

- Secure the aluminum in place with clamps if necessary. Place it firmly against the fence of your miter saw so that only the section you want to cut extends beyond it.

- Power up your miter saw and set the speed according to the type of cut you’re making.

- Line up the blade with the marks you made on the aluminum stock and turn on the miter saw motor. Apply moderate pressure to the aluminum while cutting, but be sure not to push too hard or it may cause binding in the blade. When making cuts, keep your hands well away from the blade, and always make sure the material is securely clamped down before attempting to make any cuts.

- Use slow and steady movements, and never force the blade through the material as this can cause kickback which could lead to serious injuries.

- Finish cutting when you reach your desired height for that section, then turn off the power supply and allow the blade to stop spinning before releasing any pressure from the aluminum stock.

- Finally, always unplug the saw before attempting to change blades or do any maintenance.

- Remove any debris from around your workspace or on top of your miter saw blades before returning your protective equipment and tools back into their proper places.

- Inspect the cut to make sure it meets your expectations, then you’re finished! [11]

FAQs

Can a miter saw cut aluminum?

You must use a special blade, as standard woodcutting blades will not work on metal. Plus, take care to ensure the aluminum is properly secured before attempting any cuts.

Is it OK to cut metal with a miter saw?

Yes, it is possible. However, the saw must be equipped with a specialized blade. Regular wood blades will not work and may become damaged if used to cut metal. It is also important to use the proper techniques when cutting metal with a miter saw.

What are the disadvantages of a miter saw?

The main disadvantage of a miter saw is that it can be difficult to make precise cuts. The blade must be set at exactly the right angle and depth for the cut to be accurate, and this can take some time to get used to.

Additionally, because the saw uses a spinning circular blade, there is increased risk of kickback which could lead to injury if proper safety precautions are not followed. Finally, miter saws tend to have more limited cutting capacities than other types of saws making them less suitable for larger projects or thicker materials.

What kind of saw do you use to cut aluminum?

When cutting aluminum, it is best to use a specialized saw such as an abrasive chop saw. This type of saw utilizes an abrasive wheel which runs at high speeds and provides a clean cut with minimal vibrations. It is crucial to apply the proper blade and speed settings for each material in order to avoid damaging the blade and get the best results. You can also try miter saws, but these tend to be more suited for making cross cuts in thin sheets of aluminum rather than thicker materials.

Useful Video: How to Cut Aluminum with a Mitresaw

Conclusion

To sum up, a miter saw is an important tool for any woodworker or DIY enthusiast. Its advantages include accuracy in cutting angles and easy use; the convenience of a lightweight portable saw allows for it to be taken to virtually any jobsite. To increase safety while working with a miter saw, professional grade protective equipment such as goggles or a dust mask should always be used. With all these tips in mind, you can make sure that your next project goes off without a hitch! So why not get started today? Pick up that aluminum miter saw and let your creativity flow!

References:

- https://www.cncmasters.com/how-to-properly-cut-aluminum-sheets-and-plates/

- https://www.mouldingrep.com/2022/11/28/what-is-a-mitre-saw/

- https://www.sgs-engineering.com/help-advice/which-mitre-saw-do-i-need/

- https://www.einhell.de/en/blog/workshop/the-mitre-saw-in-use/

- https://www.einhell.de/en/blog/workshop/mitre-saws-in-practical-test/

- https://www.thisoldhouse.com/tools/21014925/miter-saws

- https://www.urdesignmag.com/technology/2020/01/30/handy-benefits-and-usage-of-a-miter-saw/

- https://www.thespruce.com/how-to-use-a-miter-saw-5215560

- https://www.bobvila.com/articles/how-to-use-a-miter-saw/

- https://benchmarkabrasives.com/blogs/news/can-you-cut-aluminum-with-a-wood-blade

- https://www.protoolreviews.com/how-to-use-a-miter-saw/