Choose the Best Primer for Aluminum

Customer’s Choice: the Best Rated Primers for Aluminum

1154 users answered this survey. Please help us improve this review!

The best primer for aluminum is a question that we`ve all asked ourselves at one point or another. If you are looking to improve the look and feel of your car, then it would be wise to take some time and research what primers work well with your type of metal. There are many different types of primer available on the market which can make this task difficult, but don’t worry! We’ve compiled a list below that will help narrow down your search.

Dupli-Color – FP101 Scratch Filler & Primer

Dupli-Color’s filler primer has a high-build auto type that can fill deep scratches and minor surface flaws.

Dupli-Color’s filler primer has a high-build auto type that can fill deep scratches and minor surface flaws.VHT SP307 High Performance Self-Etch Primer

VHT’s Self-Etch primer is a high-performance product that etches and primers in one easy step. It has excellent adhesion and is ideal for small repairs. It may be used on all of today’s car finishes except for paints.

VHT’s Self-Etch primer is a high-performance product that etches and primers in one easy step. It has excellent adhesion and is ideal for small repairs. It may be used on all of today’s car finishes except for paints.Fiberglass, bare steel, aluminum, stainless steel, and plastic are all suitable applications.

Moeller 025472 Zinc Chromate Primer Green Made by Moeller

This is a high-quality product. It’s simple to apply and dries fast. The problem is twofold: first, this may only contain a limited amount of paint. Empties rapidly. Second, it’s quite costly for a rattle can primer.

This is a high-quality product. It’s simple to apply and dries fast. The problem is twofold: first, this may only contain a limited amount of paint. Empties rapidly. Second, it’s quite costly for a rattle can primer.I went through two cans in just a few days, and I was waiting for another to arrive. It’s straightforward to consume when it’s half the price for more primer than the Moeller variety.

Rust-Oleum 8781502 Stops Rust Flat Aluminum Primer

Water-based acrylic produces a durable protective coating with excellent rust prevention. It is both weather and corrosion resistant, and it is formulated for aluminum galvanized metal.Dries to the touch in 1-2 hours and covers up to 55-90 square feet.

Water-based acrylic produces a durable protective coating with excellent rust prevention. It is both weather and corrosion resistant, and it is formulated for aluminum galvanized metal.Dries to the touch in 1-2 hours and covers up to 55-90 square feet.

Prime is a foundation for good sticking and durability, and it withstands demanding, heavy-use situations. nCreates a flat gray finish that can be covered with a wide range of topcoats.

12 oz. Self Etching Primer Spray Paint

This is fantastic stuff. I’ve used a lot of this primer in the past. It’s usually the last thing to go. I’m very particular with the finish I want. The surface has to be perfect before any paint goes on.

This is fantastic stuff. I’ve used a lot of this primer in the past. It’s usually the last thing to go. I’m very particular with the finish I want. The surface has to be perfect before any paint goes on.Buyer’s guide

Comparison of Indicators for Choosing Primer for Aluminum

When selecting a primer for aluminum surfaces, it is important to consider various indicators to ensure proper adhesion, protection, and longevity of the coating. This table presents a comparison of key factors to consider when choosing a primer for aluminum, providing valuable information for making an informed decision.

| Indicator | Description |

|---|---|

| Corrosion Resistance | The ability of the primer to protect aluminum from corrosion. |

| Adhesion | The strength of bond between the primer and aluminum surface. |

| Drying Time | The time required for the primer to dry and cure completely. |

| Compatibility | The suitability of the primer for the specific type of aluminum alloy. |

| Flexibility | The ability of the primer to withstand expansion and contraction of the aluminum surface without cracking. |

| Application Method | The recommended application method for the primer (spray, brush, or roller). |

| Coverage | The area that can be covered by a specified amount of primer. |

| Durability | The longevity and resistance of the primer to wear, chipping, and peeling. |

| VOC Content | The level of volatile organic compounds emitted by the primer. |

Explanation:

- Corrosion Resistance: This indicator determines the primer’s ability to provide effective protection against corrosion, safeguarding the aluminum surface from environmental elements and enhancing its durability.

- Adhesion: This factor reflects the strength of the bond between the primer and the aluminum surface, ensuring a solid foundation for subsequent paint or coating layers.

- Drying Time: The drying time indicates how long it takes for the primer to dry and cure completely, allowing for timely completion of the coating process and subsequent steps.

- Compatibility: This indicator signifies the primer’s compatibility with specific types of aluminum alloys, ensuring optimal adhesion and performance on the chosen material.

- Flexibility: The flexibility of the primer refers to its ability to accommodate the expansion and contraction of the aluminum surface without developing cracks or compromising its protective properties.

- Application Method: This factor indicates the recommended application method for the primer, such as spray, brush, or roller, ensuring ease of use and efficient coverage.

- Coverage: Coverage denotes the area that can be covered by a specified quantity of primer, helping to estimate the quantity needed for a particular project accurately.

- Durability: Durability assesses the longevity and resilience of the primer against wear, chipping, and peeling, ensuring a long-lasting and aesthetically pleasing finish.

- VOC Content: VOC content refers to the level of volatile organic compounds emitted by the primer, with lower VOC levels being more environmentally friendly and potentially healthier for users.

FAQ

What is the purpose of primer for aluminum?

The purpose of primer is to provide a surface that adheres well to the metal, and helps the paint or coating to adhere better. Primer will also help to seal the metal and protect it from corrosion.

There are many different types of primers available, so it can be tricky to choose the right one for your project. In this article, we will discuss the best primers for aluminum.

The first type of primer we will discuss is an etch primer. Etch primers are designed to adhere well to metal surfaces, and they form a barrier that helps to prevent corrosion. Etch Primers are usually used on uncoated metals, or on metals that have been previously coated with a rust-inhibiting paint.

Epoxy primers form a tough seal on metals and they provide excellent adhesion for most other types of coatings or paints.

Many metallic surfaces require more depth in order to achieve good coverage; one way to address this is with a thicker primer. A metallic base paint will give your surface an extra boost, but it can also be used as its own stand-alone topcoat if desired.

When it comes to primers for aluminum, any of the above-mentioned types will work well. Just be sure to follow the appropriate application instructions so that you get the best results possible. Happy painting!

What is the best primer for aluminum?

There are many reasons why you might need to find the best primer for aluminum. You`re probably about to paint your house, or maybe you`ve found some old aluminum siding in a barn and want to bring it back to its former glory! Whatever the reason, knowing what makes an effective primer is key.

There are a few things to consider when choosing the best primer for aluminum. One is the type of paint you will be using. There are two types: latex and oil-based. Latex paints work well with primers that have acrylic in them, while oil-based paints work better with alkyd or resin primers.

Will any primer work on aluminum?

No, only a few primers are designed to work specifically on aluminum. If you try to use a primer not meant for aluminum, it may not adhere properly and could cause corrosion.

What paint will stick to aluminum?

This is a question that many people have, and the answer can be a little bit tricky. In general, most paints will stick to aluminum as long as you use the right primer. There are a few primers specifically designed for aluminum, and these are your best bet if you want to ensure proper adhesion.

Why does paint peel off aluminum?

Paint peels off aluminum because the metal is a good conductor of heat. When the paint gets too hot, it separates from the metal surface.

Aluminum is also a good conductor of electricity. Paint can be stripped away when the metal gets too much exposure to electrical currents and short circuits happen.

What kind of paint should I use on aluminum?

Use an epoxy-based paint like Devcon or Everdur to avoid peeling problems with your material. These two options are non-conductive and provide a strong bond between the metal surface.

Epoxy paints can be found at most hardware stores, but you may need to get it from a specific supplier for industrial materials like aluminum.

How do I prime my project?

As with any painting project, always start by cleaning your material thoroughly before priming. If you are using a degreaser, make sure to rinse the surface with water and let it dry completely before applying primer.

If your material has been painted in the past, then use an aluminum cleaner to remove old paint residue from surfaces. Let this sit on your metal for at least 30 minutes before rinsing off thoroughly again.

How do you prepare aluminum for epoxy primers?

Before applying coatings, you’ll need to prepare the surface. Aluminum needs a detailed preparation process before receiving any epoxy primer or paint. First, clean your aluminum with soap and water to remove all dirt and oil. Then dry it off using a soft cloth so there is no moisture on the metal’s surface. Remove rust by wire brushing the surface to the extent possible. You can also use a rust-removing product like Evapo-Rust or Naval Jelly.

For best results, we recommend using epoxy primer on bare metal surfaces because of its durability and adhesion qualities; however, if you want to use a different type of primer, follow the manufacturer’s recommendations.

In addition, you should prime your metal before painting any objects that have been welded or cut so there won’t be any exposed bare metal which could cause rusting in the future.

Do you need to prime aluminum before painting?

If you do, then choose the best primer for aluminum that will give you great results. This is not an easy task because there are many primers out in the market and choosing one can be quite confusing.

Fortunately, we have compiled a list of the best primers for aluminum that you can use. Read on to find out more!

Aluminum is a very popular metal because it is strong and durable. However, it also has a tendency to corrode when exposed to certain elements, such as water and air. This is why it is important to prime aluminum before painting it.

Primers form a protective layer on the surface of the metal and help to prevent corrosion. They also provide a good base for the paint to adhere to, which means that your paint will look better and last longer.

There are many primers available in the market, but not all of them are suitable for aluminum. The best primers for aluminum are those that have been specifically designed to work with this metal.

Can aluminum be painted black?

Yes, aluminum can be painted black. There are a few different ways to do this, but the most common is to use anodizing. Anodizing is a process that coats the metal with a layer of oxide, which makes it resistant to corrosion and scratches. It also gives it a dark color that can vary from black to very dark green.

If you’re looking for a black paint that will stick well to aluminum, we recommend using an automotive-grade primer. This type of primer is designed to adhere to difficult surfaces like metal and plastic, and it will give your paint job a lasting finish.

Can you paint aluminum wrap that is chipping?

Yes, it is possible to paint aluminum that is chipped. You just need a primer and some patience while using an oil based exterior paint.

You will be sure to get the best results when you use a high quality spray gun and don`t rush through this job. Aluminum can chip or peel if you try to apply too much pressure.

Make sure to use a primer that is specifically designed for metal surfaces. A good option would be an epoxy-based primer. This type of primer will form a protective layer on the aluminum and help to prevent future chipping or peeling.

Once the primer has dried, you can start painting with your oil based exterior paint.

You should apply thin layers of paint at a time and let each layer dry before adding another one. This will help ensure your final product looks good when finished!

Can you paint aluminum with hammerite?

Primers for aluminum can be a little confusing. You may ask, “Can you paint aluminum with hammerite?” The answer is yes! There are even some specific primers that work best on metal surfaces as well as other things like wood and plastic. In this blog post we will go over the best primer options available for aluminum surfaces.

One of the best primers for aluminum is actually a spray paint primer. Krylon makes a great one called Fusion that can be used on both indoor and outdoor projects. It dries quickly and doesn’t require any sanding between coats, making it a perfect choice for quick touch-ups or small projects.

How do I remove peeling paint from aluminum?

There are a few ways to remove peeling paint from aluminum. You can use a chemical stripper, or you can use a heat gun.

If you’re using a chemical stripper, be sure to read the instructions carefully and wear the appropriate safety gear.

If you’re using a heat gun, be very careful not to damage the aluminum. Start by heating the paint until it’s soft, then use a scraper to remove the paint.

Once the paint is removed, you’ll need to clean and polish the aluminum. Use a mild detergent and a soft cloth to clean it, then apply a polishing compound to give it a shine.

Does epoxy paint stick to aluminum?

Epoxy paint sticks to aluminum with an epoxy primer. And, depending on the porosity of your surface and how well it is prepped, you may only need one coat or as many as three coats if there are major imperfections in your metal surface. A good product for all-purpose priming aluminum surfaces like those used in boatbuilding is Pettit’s EZ-Prime. It dries fast, sands easily and has a built-in corrosion inhibitor to keep your metal looking good for years to come.

If you are painting over an existing coat of paint on aluminum, make sure that the old paint is in sound condition and adheres well to the surface. And if the old paint’s gloss is high, you will need to clean it with a deck sander and heavy duty cleaner before applying primer.

In addition to being used for aluminum boats, EZ-Prime also works well as an all purpose metal priming compound that can be applied by brush or roller over bare metal, galvanized metal, or aluminum that has been previously painted. For the best results on boats and other watercraft, use a brush to get into all the nooks and crannies for a good coat of primer.

How does primer protect aluminum surfaces?

Primer for aluminum surfaces provides a protective barrier that helps prevent corrosion and oxidation. It creates a strong bond between the aluminum substrate and the paint, ensuring better adhesion and durability of the paint coating. The primer acts as a foundation, promoting long-lasting paint performance and enhancing the overall appearance of the aluminum surface.

What are the key components of a primer for aluminum?

Primer for aluminum typically contains essential components such as corrosion inhibitors, adhesion promoters, and resins. Corrosion inhibitors prevent the formation of rust or corrosion on the aluminum surface, while adhesion promoters help the primer adhere securely to the metal substrate. Resins provide the necessary strength and durability to the primer, ensuring it can withstand environmental conditions and provide a stable base for the paint.

How should I prepare the aluminum surface before applying a primer?

Before applying a primer, it is crucial to prepare the aluminum surface properly. Start by cleaning the surface using a mild detergent and water to remove any dirt, grease, or contaminants. Next, lightly sand the surface with fine-grit sandpaper to create a rough texture, which improves the adhesion of the primer. Finally, wipe the surface clean with a lint-free cloth to remove any dust or residue before applying the primer.

Can I use a self-etching primer for aluminum?

Yes, self-etching primers are suitable for use on aluminum surfaces. These primers contain acid-based compounds that chemically etch the metal, creating a strong bond between the primer and the aluminum. Self-etching primers are particularly effective in promoting adhesion and preventing corrosion on aluminum surfaces. However, it is important to follow the manufacturer’s instructions and ensure proper surface preparation for optimal results.

How long does it take for the primer to dry before applying paint?

The drying time of the primer before applying paint can vary depending on factors such as temperature, humidity, and the specific primer product used. It is essential to refer to the manufacturer’s instructions for the recommended drying time. In general, most primers for aluminum surfaces require at least 30 minutes to a few hours to dry completely. However, it is advisable to allow the primer to cure for a full 24 hours before applying paint to ensure proper adhesion and longevity of the paint coating.

Can I apply multiple coats of primer on aluminum?

Applying multiple coats of primer on aluminum surfaces is generally unnecessary and may not provide significant benefits. A single, well-applied coat of primer should be sufficient to achieve proper adhesion and protection for the aluminum substrate. Excessive primer buildup can lead to uneven paint application and potentially affect the final appearance. If you feel that additional primer is required, consult the manufacturer’s guidelines or seek professional advice.

Do I need to sand the primer before applying paint?

Sanding the primer before applying paint is not typically necessary. However, if the primer surface is rough or shows imperfections, you may lightly sand it using fine-grit sandpaper to create a smoother surface for the paint. Be cautious not to sand through the primer and expose the bare aluminum. After sanding, wipe the surface clean with a lint-free cloth to remove any dust or debris before proceeding with the paint application.

Can I paint over an existing primer on aluminum?

Yes, you can paint over an existing primer on aluminum surfaces. If the existing primer is still in good condition and provides a suitable base, there is no need to remove it before applying a new coat of paint. However, it is important to ensure that the existing primer is clean, free of defects, and properly adhered to the aluminum surface. If the primer is damaged or compromised, it is advisable to remove it and reapply a fresh coat of primer before painting.

What type of paint is recommended for use over aluminum primer?

Once the primer has dried or cured, you can use various types of paint suitable for aluminum surfaces. Common options include acrylic, enamel, or epoxy-based paints. It is important to select a paint that is specifically formulated for metal applications and offers good adhesion and durability. Consult the paint manufacturer’s recommendations and instructions to ensure compatibility with the primer and desired finish on the aluminum surface.

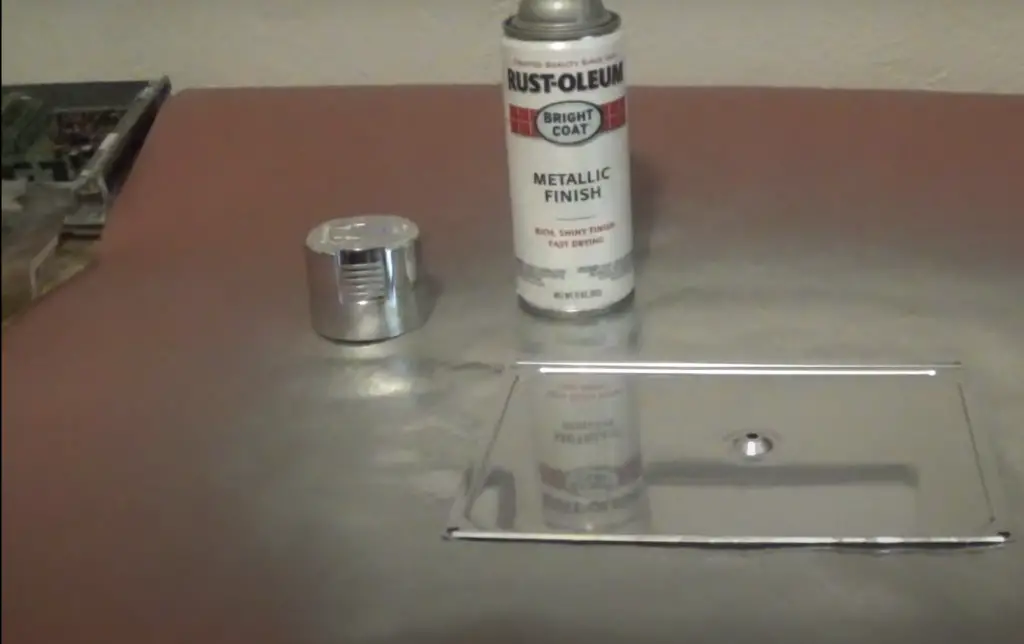

Useful Video: Painting Aluminum, Spray Can Primers Compared

Conclusion

A primer is a great way to protect your aluminum from corrosion and wear. It also helps the paint stick better so it will last longer. There are several brands of primers on the market today but there are some that stand out among others because they do their job well, have fewer environmental concerns or come with additional benefits for you as a consumer.