Choose the Best Paint for Aluminum Screen Enclosure

Customer’s Choice: the Best Rated Paints for Aluminum Screen Enclosures

347 users answered this survey. Please help us improve this review!

If you’re looking for the best paint to use on your aluminum screen enclosure, you’ve come to the right place. In this article, we’ll discuss the different types of paints that are available and why each one might be a good choice for your project. We’ll also provide some tips on how to choose the right paint for your needs. So whether you’re just getting started with your project or you’re ready to pick out your paint color, read on for all the information you need!

One of the most important things to consider when choosing a paint for your aluminum screen enclosure is what type of finish you want. There are three main types of finishes: glossy, semi-gloss, and flat. Each one has its own advantages and disadvantages, so it’s important to choose the right one for your project.

Glossy finishes are the most durable and easy to clean, but they can also be the most difficult to apply. If you’re not careful, you can end up with streaks or brush marks in your paint job.

Semi-gloss finishes are a good compromise between durability and ease of application, and they’re also easier to touch up if you make a mistake.

Flat finishes have the least amount of durability, but they’re the easiest to apply and touch up.

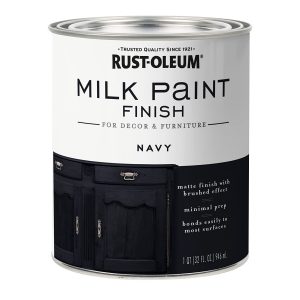

Rust-Oleum 331051 Milk Paint Finish, Quart

If you’re looking for a unique way to add some flair to your home decor, then Rust-Oleum 331051 Milk Paint Finish is the perfect product for you. This water-based formula dries to a lightly textured matte finish, and can be used to accent details on interior decor and furniture.

If you’re looking for a unique way to add some flair to your home decor, then Rust-Oleum 331051 Milk Paint Finish is the perfect product for you. This water-based formula dries to a lightly textured matte finish, and can be used to accent details on interior decor and furniture.

This paint is not recommended for surfaces that will get heavy wear, but it can give your projects an aged appearance with a bit of wear and tear.

So if you’re looking for an easy way to refresh old furniture or add some personality to your home, Rust-Oleum 331051 Milk Paint Finish is the perfect choice.

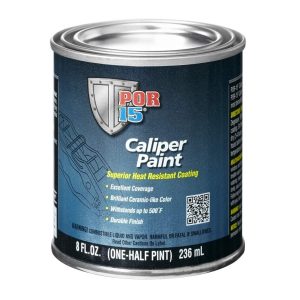

POR-15 Caliper Paint – 8 fl. Oz.- Superior Heat Resistant Coating – High Temperature Brake Caliper Paint

Are you looking for a tough and attractive coating for your car’s calipers? Look no further than POR-15 Red Caliper Paint! This formulated paint will resist the brake dust produced by harsh braking conditions, providing you with a long-lasting and good-looking finish.

Are you looking for a tough and attractive coating for your car’s calipers? Look no further than POR-15 Red Caliper Paint! This formulated paint will resist the brake dust produced by harsh braking conditions, providing you with a long-lasting and good-looking finish.

However, if you want this to look well and last, take your time and be prepared.

So if you’re looking for a top quality caliper paint that won’t let you down, go with POR-15 Caliper Paint.

Krylon, Black I00807 Chalkboard Aerosol Spray Paint

Introducing Krylon Black I00807 Chalkboard Aerosol Spray Paint! This easy-to-use spray paint creates a tough, slate-like chalkboard surface that is perfect for writing and drawing. The durable, long-lasting finish resists smudging and fading, making it ideal for surfaces that get a lot of use.

Introducing Krylon Black I00807 Chalkboard Aerosol Spray Paint! This easy-to-use spray paint creates a tough, slate-like chalkboard surface that is perfect for writing and drawing. The durable, long-lasting finish resists smudging and fading, making it ideal for surfaces that get a lot of use.

You may need to use a wet cloth or sponge to remove the chalk completely. But overall, this is a great product that can help you get creative with your home decorating or school projects.

Rutland Products, Black Rutland 1200-Degree F Brush-On Flat Stove Paint

Looking to update your stove or grill? Rutland Products has you covered with their Black Rutland 1200-Degree F Brush-On Flat Stove Paint. This paint adheres to steel, cast iron, aluminum, brick, and most other metals, making it a great option for a range of projects.

Looking to update your stove or grill? Rutland Products has you covered with their Black Rutland 1200-Degree F Brush-On Flat Stove Paint. This paint adheres to steel, cast iron, aluminum, brick, and most other metals, making it a great option for a range of projects.

Although the paint does have a strong smell while it is being applied, this will dissipate within a few hours, so it’s not something you need to worry about long-term. The only downside to this product is its price point, which is higher than some of its competitors.

However, we believe that the quality of the paint more than justifies the cost.

POR-15 High Temperature Paint

Looking for a high-temperature paint that can withstand the extreme heat? Look no further than POR-15 High Temperature Paint! This tough and durable paint is capable of withstanding temperatures of up to 1200°F / 648.8°C, making it ideal for protecting metal surfaces that are subject to extreme heat.

Looking for a high-temperature paint that can withstand the extreme heat? Look no further than POR-15 High Temperature Paint! This tough and durable paint is capable of withstanding temperatures of up to 1200°F / 648.8°C, making it ideal for protecting metal surfaces that are subject to extreme heat.

It also has a strong smell that will linger long after the paint has dried, so be sure to apply it in a well-ventilated area. Despite its high price, POR-15 High Temperature Paint is worth the investment for anyone who wants the best possible protection for their metal surfaces.

Buyer’s Guide

Picking Paint for Aluminum Screen Enclosures

Aluminum screen enclosures are a great way to enjoy the outdoors without being bothered by insects. But what kind of paint should you use on aluminum screen enclosures? The best paints for aluminum screen enclosures are usually either oil-based or acrylic. Here’s a look at some of the best paints for aluminum screen enclosures and why they’re so good.

It’s also important to pick a paint that’s right for the climate in your area.

Finally, make sure to follow the manufacturer’s instructions for applying the paint. If you don’t, you could end up with a poor-quality finish that won’t last very long.

Types of Paint for Aluminum Screen Enclosures

Oil-based paints

Oil-based paints are great for aluminum screen enclosures because they provide a durable finish that can withstand the elements.

Pros of oil-based paints:

- Durable;

- Can withstand the elements;

- Smooth application and excellent coverage;

- You can use oil-based paints to stained, chalky or dirty surface;

- Oil paint performs better at concealing minute flaws or mildly damaged areas;

- According to some professionals, oil-based paint has considerably richer color than water-based paint;

Cons oil-based paints:

- May require more than one coat;

- May require a primer;

- Can be difficult to apply;

- Can yellow over time;

- Not touchable in small areas without leaving visible marks;

- High VOC (Volatile Organic Compound) level; [1]

Acrylic paints

Acrylic paints are also a good choice for aluminum screen enclosures because they resist fading and chalking.

Pros of acrylic paints:

- Also provide a durable finish;

- Withstand the elements;

- Resist fading, chalking, and yellow;

- Non-toxic;

- Low VOC level;

- Water can be used to dilute acrylic paints;

- Flexible and strong

Cons of acrylic paints:

- Some color bleed may occur while painting with wet acrylics over dry ones;

- A rapid drying time;

- Meaning you need to work quickly;

- It’s hard to remove from nails or clothing once dried.[2]

Self-Etching Primer

A rust-prevention coating called self-etching primer etches and primes in one application. This type of primer is ideal for new projects, as well as repairing old paint jobs. It’s perfect for aluminum screen enclosures because it adheres well to metal and provides excellent corrosion resistance.

Pros:

- Aids in the adhesion of paint to the surface;

- Helps the paint to last longer;

- Resists fading and chalking.

- Adheres well to metal;

Cons:

- May require more than one coat;

- Can be difficult to apply. [3]

With these tips in mind, you should be able to find the best paint for your aluminum screen enclosures.

6 steps to Painting Aluminum Screen Enclosures

If you have an aluminum screen enclosure, you know that it’s important to keep it looking good. Paint can help protect the metal from the elements and make it easier to clean. But not all paints are created equal. Here are six things to consider when choosing a paint for your aluminum screen enclosure.

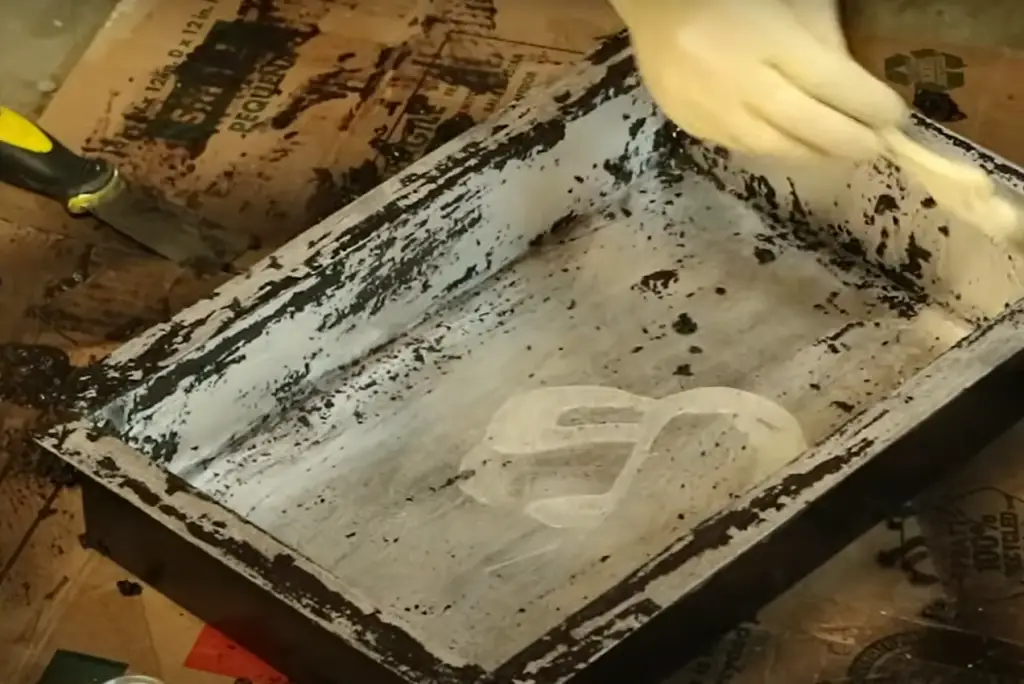

Sand down metal

You’ll want to sand down the metal screen before you start painting. This will help the paint to adhere better and create a smoother surface. Be sure to use a fine-grit sandpaper so you don’t damage the screen.

The fresh paint won’t adhere as well if the old paint is left in place. Additionally, the new paint will chip since the old paint is still flaking and rusting underneath. The aluminum should be completely smooth and rust-free after being sanded.

Wash and dry

After you’ve sanded the screen, wash it with soap and water to remove any dust or debris. Put on protective gloves depending on your preference. Work your way up and down with a fresh cloth. Then, dry it completely before you start painting.

Protection

Cover everything you don’t want to get paint on before you start painting. This includes the ground, any furniture, and any other surfaces. You can use a drop cloth or plastic sheeting to protect these areas.

Primer

Now that everything has been cleaned, protected, and sanded, you may begin painting. Using a self-etching primer as an undercoat can help you properly prepare the surface. You need as much grip as you can get since aluminum is a non-porous surface.

For this stage, use a brush or a sprayer. If you’re using a brush, look for one that’s designed for use with metal. This type of brush will have synthetic bristles that are less likely to shed.

Paint

Now it’s time to choose your paint color and type.

For the best results, use an acrylic latex paint specifically designed for metal surfaces. These paints are available in both a glossy and satin finish. Because of their endurance, oil-based paints won’t end up peeling on you. The only drawback is that they frequently only come in glossy finishes.

In terms of exterior paint, latex paint comes in second place. If you want more alternatives for the sort of finish and only have moderate seasons, this is a fantastic option. Start painting at the top and work your way down, moving from side to side. By doing so, you may line up the various areas and provide an even coat.

If you’re not sure which one to choose, test a small area first.

Seal

It’s finally time to complete your project! Just as crucial as priming the surface is sealing your freshly painted surface.

You can find sealants specifically designed for metal surfaces at most hardware stores.

Now that you know how to paint aluminum screen enclosures, you can keep yours looking great for years to come! Just follow these simple steps and choose the right products, and you’ll be well on your way.

Comparison of Indicators for Choosing Paint for Aluminum Screen Enclosures

Choosing the right paint for your aluminum screen enclosures is essential to achieve a long-lasting and visually appealing finish. This table presents a comparison of key indicators to consider when selecting paint for aluminum screen enclosures. The indicators include coverage, drying time, durability, and recommended applications.

| Indicator | Value |

|---|---|

| Coverage per Gallon (in square feet) | 400-500 |

| Drying Time (in hours) | 2-4 |

| Durability | Good |

| Recommended Applications | Residential, light-duty use |

Explanation to the table:

- Coverage per Gallon (in square feet): Indicates the approximate area that can be covered by one gallon of paint. This helps estimate the quantity of paint needed for your aluminum screen enclosures.

- Drying Time (in hours): Specifies the time required for the paint to dry completely before it is safe to touch or apply additional coats. Faster drying times may be preferred to reduce project duration.

- Durability: Reflects the paint’s ability to withstand various elements such as weather conditions, UV rays, and wear. A good durability rating ensures a long-lasting finish.

- Recommended Applications: Suggests the ideal usage scenarios for the paint. In this case, the paint is recommended for residential applications with light-duty use, indicating it is suitable for typical residential screen enclosures.

Please note that the values provided in the table are generic examples and may vary depending on the specific paint products available in the market. It is advisable to consult product labels, manufacturer instructions, and seek professional guidance to select the most appropriate paint for your aluminum screen enclosures.

FAQ

Can you paint an aluminum screen enclosure?

Yes! You can paint an aluminum screen enclosure with the right type of paint. Be sure to choose a paint that is specifically designed for metal surfaces, such as an oil-based enamel paint. You’ll also need to take special care to clean and prepare the surface before painting it.

In order to give the aluminum screen enclosure a great finish, we decided to spray paint it. Typically, one coat of paint is enough to cover the aluminum screen enclosure’s previous paint layer.

What kind of paint works best on aluminum?

The best paint for an aluminum screen enclosure is one that will protect the metal from the elements and keep it looking its best. There are several different types of paints that can be used on aluminum, but not all of them will provide the same level of protection. Oil-based enamel paint is a good option for an aluminum screen enclosure because it will stand up to the elements and provide a long-lasting finish.

What is the best paint for outside aluminum?

The best paint for outside aluminum is an oil-based enamel paint. This type of paint will provide a long-lasting finish that can withstand the elements.

Make sure there are no brush or roller markings left behind while applying paint. When you need to go up there again, any paint buildup from uneven rolls will be apparent. Then, finish it off with a sealer to shield it from dirt and peeling, just like you did with the other components of the enclosure.

How do you paint aluminum screen cages?

To paint an aluminum screen cage, you will need to clean the surface and then apply a primer before painting.

Why should you paint an aluminum screen enclosure?

Painting an aluminum screen enclosure can help to protect the metal from the elements and keep it looking its best. A fresh coat of paint will also make the enclosure more durable and easier to clean. Whether you’re painting a new screen enclosure or repainting an old one, be sure to choose a paint that is specifically designed for metal surfaces.

Will paint stay on aluminum?

Aluminum will retain its paint if it is properly primed. Using a primer will significantly slow down the oxidation of aluminum, which happens naturally over time. Even with a sealer, if new paint is sprayed or painted over existing paint, the foundation will still be insufficient to prevent chipping.

Can You Paint a Screen?

To use screens, you’ll need things like hard, nonporous surfaces because they take paint poorly. An acidic primer will aid in establishing long-lasting adherence. Tiny mesh holes in a wire screen are easily cleaned with primer and paint.

Can You Paint an Aluminum Screen Porch?

Aluminum screen porches are a great way to enjoy the outdoors without worrying about pests. But can you paint an aluminum screen porch?

Yes, you can! Just like any other type of surface, painting your aluminum screen porch is a great way to add extra protection and style.

Gloss finish latex paint is the best kind to use on aluminum surfaces. With the gloss surface, you can clean the porch more quickly. For aluminum-containing surfaces, latex enamel works best. On a dry day, apply latex paint, and then wait for it to dry completely before adding another coat.

Can You Paint Fiberglass Screens?

Yes, you can paint fiberglass screens! Just like any other type of surface, painting your fiberglass screen is a great way to add extra protection and style.

By painting your window screens with a little paint and gentle pressure, you can transform them into works of art. Those who are unfamiliar with this art form may find it to be rather puzzling. Even though you might not be able to view the design via the screen, if there is any backdrop shade or darkness, the painting can still be seen.

Can You Paint A Pool Screen Enclosure?

You bet you can! In fact, painting your pool screen enclosure is a great way to add a pop of color and personality to your backyard oasis. Painting your pool surround is a more affordable option than starting from scratch. While saving you thousands of dollars, our Direct-to-metal paints will bring back the sparkle to your pool enclosure.

What are the necessary steps to prepare an aluminum screen enclosure for painting?

Before painting an aluminum screen enclosure, you need to follow these steps for proper preparation:

a) Clean the surface: Remove any dirt, dust, or debris from the enclosure using a mild detergent and water solution. Rinse thoroughly and allow it to dry completely.

b) Remove old paint or coatings: If there are any existing paint or coatings on the aluminum, use a paint stripper or sandpaper to remove them. Ensure that the surface is smooth and free from any loose paint.

c) Repair any damages: Inspect the enclosure for any dents, scratches, or holes. Use a suitable filler or putty to repair these imperfections and sand them down for a smooth finish.

d) Prime the surface: Apply a suitable primer specifically designed for aluminum surfaces. This will promote adhesion and help the paint to adhere better.

e) Mask and protect: Cover any areas that you don’t want to paint, such as glass panels or nearby structures, using painter’s tape and plastic sheets.

What type of paint should I use for painting an aluminum screen enclosure?

For painting an aluminum screen enclosure, it is recommended to use a high-quality exterior-grade paint that is specifically formulated for metal surfaces. Look for paints labeled as “aluminum paint” or “metal paint” to ensure they adhere well and provide long-lasting protection.

Choose a paint that is designed for outdoor use and offers excellent weather resistance, UV protection, and durability. Additionally, opt for a paint with good coverage and a finish that suits your preference, such as satin, semi-gloss, or gloss.

How do I apply paint to an aluminum screen enclosure?

Here’s a step-by-step guide to applying paint on an aluminum screen enclosure:

a) Stir the paint: Thoroughly mix the paint before application to ensure consistent color and texture.

b) Use a brush or roller: Choose a high-quality brush or roller that is suitable for the type of paint you are using. Start by applying paint to the corners and edges using a brush and then use a roller to cover larger areas.

c) Apply multiple coats: Apply the paint in thin, even coats rather than trying to achieve full coverage in a single coat. Allow each coat to dry completely before applying the next one.

d) Follow the manufacturer’s instructions: Pay attention to the recommended drying times between coats and the number of coats suggested by the paint manufacturer.

e) Touch up and finish: After the final coat, inspect the painted surface for any missed spots or imperfections. Touch up these areas as necessary and let the paint cure according to the manufacturer’s instructions.

Should I use a primer before painting an aluminum screen enclosure?

Using a primer before painting an aluminum screen enclosure is highly recommended. Primers create a smooth and uniform surface, enhance paint adhesion, and provide better durability.

Choose a primer that is specifically formulated for use on metal surfaces, such as aluminum. Apply the primer according to the manufacturer’s instructions, ensuring complete coverage of the aluminum surface. Once the primer has dried, you can proceed with applying the paint.

How long does the paint on an aluminum screen enclosure typically last?

The longevity of paint on an aluminum screen enclosure can vary depending on several factors, including the quality of the paint used, the climate conditions, and the level of maintenance.

Generally, a well-applied high-quality paint on an aluminum screen enclosure can last for several years. With proper care and maintenance, such as regular cleaning and touch-ups as needed, you can extend the lifespan of the paint and maintain its appearance for an extended period.

Keep in mind that exposure to harsh weather conditions, such as intense sunlight, heavy rain, or extreme temperature changes, can impact the paint’s durability. Regular inspection and maintenance will help identify any areas that require repainting or touch-ups.

Useful Video: Painting Aluminium Windows

Conclusion

Painting your aluminum screen enclosure can be a great way to improve its appearance and protect it from the elements. But what type of paint should you use? We’ve compiled a list of the best paints for aluminum screen enclosures, so you can choose the right one for your needs. Whether you’re looking for a durable paint that will stand up to weathering or a beautiful finish that will enhance your home’s curb appeal, we have you covered. So what are you waiting for? Start browsing our selection of the best paints for aluminum screen enclosures today!

References:

- https://www.networx.com/article/oil-based-paint

- https://outlinesart.com/articles/advantages-and-disadvantages-of-acrylic-paints/

- https://dfarq.homeip.net/self-etching-primer/