Choose the Best Tungsten for Stainless Steel

Customer’s Choice: the Best Rated Tungsten for Stainless Steel

110 users answered this survey. Please help us improve this review!

Expanded tungsten is a popular choice among those looking to use metal for stainless steel applications, but not all types work well. We’ll answer any questions you may have about how it works and help get the right product if needed.

Midwest Tungsten Service TIG Welding Tungsten Electrodes (Red)

Tungsten is a great choice for those who want to weld stainless steel with the thoriated tungstens. It is affordable and it also provides high-quality results.

Tungsten is a great choice for those who want to weld stainless steel with the thoriated tungstens. It is affordable and it also provides high-quality results.

Be careful, it can be splitting sometimes, and the quality of the packing is low.[1]

WeldingCity 10-pk Premium TIG Welding Tungsten Electrode

At a diameter of just over three thirty-seconds of an inch and seven inches in length, these are one of the smaller options on the market.

At a diameter of just over three thirty-seconds of an inch and seven inches in length, these are one of the smaller options on the market.

They are made with high-quality, lanthanated powder. The sharp points make it easier to start an arc and there are fewer welding defects because the material is of a higher quality and lasts longer than most other materials on the market today.

Be aware that it does not handle AC current, and be careful as it consumes at a faster rate than 2% lanthanated electrodes. They get beat up quick, running under 140 amps. But despite all that, this is still the electrode of choice for discerning welders who know that only the best will do. When you need a tough, dependable welding electrode that won’t let you down, go with WeldingCity. [2]

Midwest Tungsten Service TIG Welding Tungsten Electrodes (Green)

The 99% concentration of these high grade metals ensure that your weld joint will be strong and durable. They also produce a low burn off rate which means you won’t have to replace them as often!

The 99% concentration of these high grade metals ensure that your weld joint will be strong and durable. They also produce a low burn off rate which means you won’t have to replace them as often!

Welders sometimes have trouble joining two types of metal because the metals can have different melting temperatures. Even though tungsten has a high melting point, it can still be used to weld metals with much lower melting points, like stainless steel.

The tungsten electrode is also known for being able to create very thin and precise welds. This is important when working on projects that require a high level of detail.

They are made from pure tungsten so that your arc will be good and you won’t have to worry about the burn rate as much as you would with other products on the market. This AC unit also does a great job in many other settings, such as power plants across the nation. You can trust that this is efficient and knows exactly where every gram of energy goes.

If you’re looking for a perfect weld every time, then Midwest TIG Welding’s tungsten electrodes are what you need. These rods are of high quality and come in the package. However, if they are not taken care of properly, they may cause problems. That is why it is important to check carefully inside each package before using them, so you don’t damage the contents or break them easily during transport. [3]

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Gold)

You can use these gold-colored tungsten electrodes for welding stainless steel.

You can use these gold-colored tungsten electrodes for welding stainless steel.

They’re made of 99% pure, high-quality material that can perform well in both AC and DC applications with low burn off rates for optimal performance on your project! If you need an excellent welder’s tool or just want something special as decoration then this is it – call them today before they run out.

Midwest TIG Welding’s tungsten electrodes are perfect for welders who want a consistent and high-quality result every time. The kit comes with everything you need to move your things. But before you use the rods, you need to check them carefully. This is so that you don’t damage yourself or the breakable items during transport. [4]

GYS 10 Pcs Tungsten Electrodes For AC/DC Yellow

The GYS tungsten electrodes are perfect for AC/DC welding of steel and stainless steel. The diameter is only 0.045 inches, making it the perfect size for welding in tight spaces. The yellow color makes it easy to see, even in low light conditions.

The GYS tungsten electrodes are perfect for AC/DC welding of steel and stainless steel. The diameter is only 0.045 inches, making it the perfect size for welding in tight spaces. The yellow color makes it easy to see, even in low light conditions.

If you’re looking for the best tungsten electrode, the GYS 045330 is a great option. It’s made from durable materials, it’s compatible with both AC and DC current. Plus, it’s a great value for the price.[5]

Buyer’s Guide

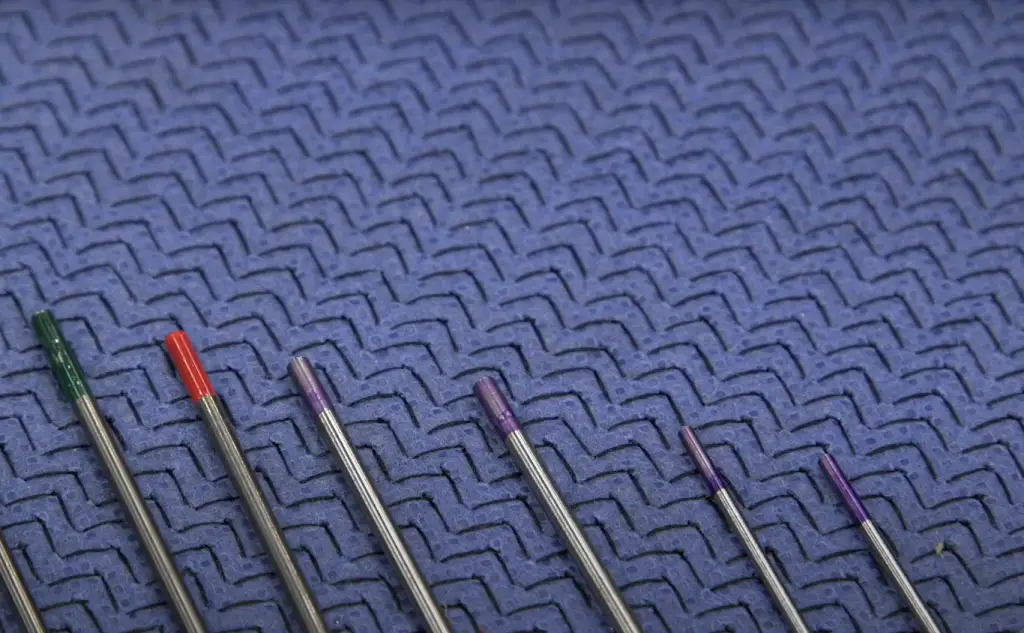

Types of Tungsten Electrodes

There are three main types of electrodes: pure tighten, thorium-togensnd zirconium – each with its own unique benefits and drawbacks. Depending on the application you use them for, one type may be better or worse than the others.

Thorium-tungsten is the most common type of electrode. It has a higher melting point than pure tungsten, which makes it ideal for use in high temperatures. However, it also has a higher rate of arc wander than pure tungsten.

Pure Tungsten is a great choice for those who need to weld at low temperatures or in applications where durability isn’t as important.

Thorium-Tungsten is more wear resistant than pure and has a higher melting point. However, it’s also more expensive and can be more difficult to work with.

Zirconium-Tungsten is a strong and durable metal that can resist the most challenging conditions. This metal has a high melting point, which makes it perfect for welding. If there are gaps between joints or cracks on materials, this metal can be used without compromising their safety. This is because the metal does not overheat from the friction caused by contact heat generation when held too long at close proximity against each other.

In general, pure tungsten or thorium-tungsten will work fine. [6]

Tungsten Applications

Tungsten is a mineral that is found on Earth. It can only be mined from certain places where it is mixed with other minerals. People have found tungsten since 1800 BC.

Tungsten is a metal that is very hard and resistant to wear. Tungsten is a very useful element because it has a high melting point. This means that it is perfect for making tools that need to be very strong and for making electrical wiring.

Tungsten’s unique properties make it perfect for a number of applications. Here are just a few:

- Tungsten is often used in jewelry (in rings and watches). It is strong and resistant to wear.

- Tungsten is used in making electrical wiring. It can handle very high temperatures.

- Tungsten is used to make tools that need to be very strong, such as drill bits and saw blades.

- Tungsten is used in making light bulbs. It has a very high melting point.

- Which Tungsten Electrode is Best for Your Application?

Tungsten is a versatile metal that can be used for a variety of purposes.

Stainless steel has many various types. The most common welding process used to make this type of metal is GTAW (TIG) or MIG welds. It depends on the properties you need in the final product. There’s also the SS400, which uses an air arc but doesn’t require any filler rod.

There are two types of batteries – those made from stainless steel, and those made from carbon. The carbon batteries use cobalt and manganese dioxide.

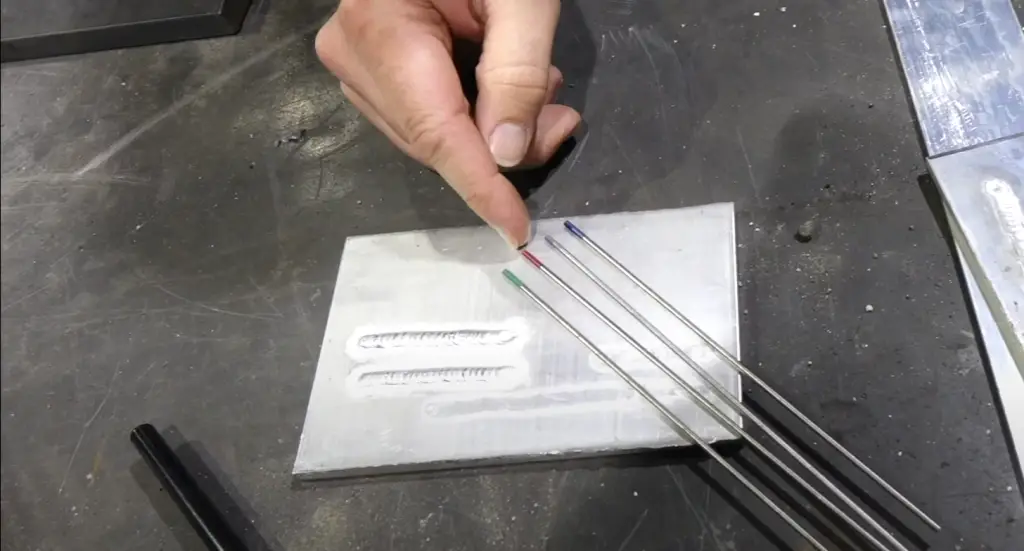

What Size Tungsten Is Ideal For TIG Welding?

The sweet spot for TIG welding lies between .040″-.0625″, or what’s commonly called “40-sixty.” Larger electrodes are harder to control than smaller ones. However, smaller electrodes may not provide enough heat to weld thicker materials properly. That said, there are some applications where a slightly smaller or larger electrode may be necessary.

This will help prevent the tungsten from puncturing through the material and ruining the weld. On the other hand, when welding thick materials (over ½”), it’s often necessary to use a larger electrode like .0625″ or even .09375″. This will help ensure that the weld puddle has enough time to form before the tungsten electrode melts.

It’s much easier to control a large electrode than a small one, and it’s also less likely to break. If you’re not sure which size to use, start with .040″-.0625″ and go from there. [8]

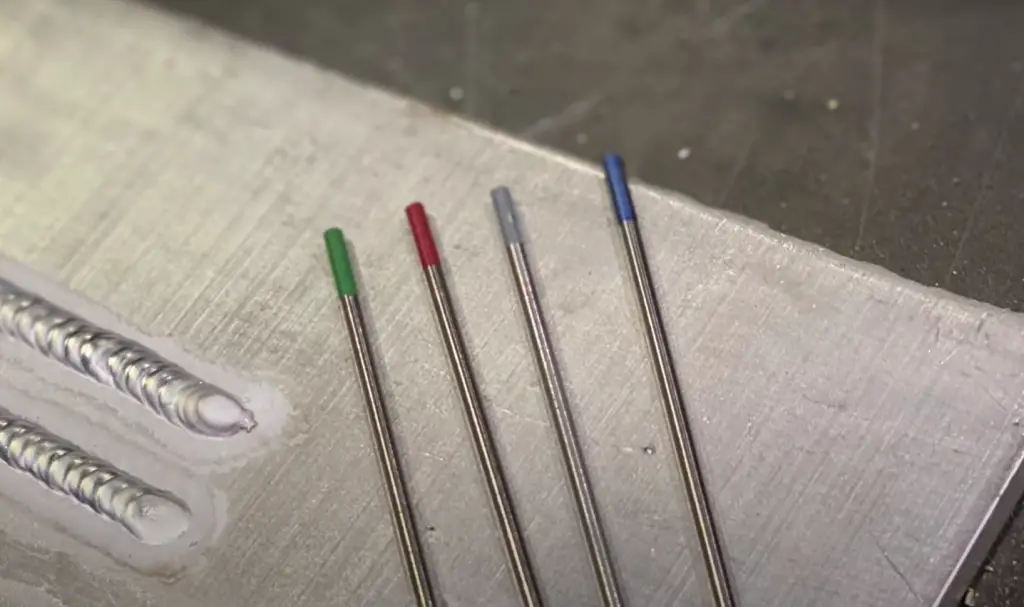

Which Is The Best Tungsten For TIG Welding Stainless Steel?

There are many factors to consider when choosing a tungsten for TIG welding stainless steel.

The most important factor is the alloy’s composition, as different alloys will have different properties that make them better or worse for specific applications.

The next factor is the diameter of the electrode, as a thicker electrode will be more durable but also more difficult to control. Finally, you must also consider the price of the tungsten, as some alloys can be quite expensive.

With that said, let’s take a look at three of the best tungstens for TIG welding stainless steel:

- thorium tungsten (ThW)

- cerium tungsten (CeW)

- lanthanated tungsten (LaW)

Thorium is a radioactive metal that is found in small amounts in many rocks and minerals. When thorium is combined with tungsten, it creates an alloy that is very strong and resistant to wear. It also has a high melting point, making it ideal for welding stainless steel.

Cerium is an alloy that contains between 60-80% tungsten and 20-40% cerium. This alloy is known for being easy to start and having good arc stability. Additionally, cerium tungsten produces less slag than other alloys, making it easier to weld stainless steel.

Lanthanated Tungsten is a material that can be found with between 55 and 85% tungsten, and between 15 and 45% lanthana. This alloy is known to be easy to start and have good arc stability. It also burns cool when heated up quickly by an electric lighter or flame light bulb. [8]

What Are Differences Between Red and Blues Tungsten?

The main difference between red and blue tungsten is the way they are made. Red tungsten is made by heating a powder mixture until it is solid. Blue tungsten is made by melting the metal and then quickly cooling it. This process makes blue tungsten a denser material, which is better for welding and other applications that need a high density.

Red tungsten is often the choice for those looking to save money. It’s also easy on your heating budget because it has a lower melting point than blue metal does. Red isn’t as strong or durable as other colors, but it can save you some money. If you need something that will last for a long time, then this might not be the best choice for you. But I think we can all agree that saving money makes life more enjoyable.

If you’re not sure which type of tungsten to choose, consult with a professional. They will be able to help you select the best tungsten for your application.

FAQ

Which Colored Tungsten Is Best For Welding Mild Steel?

Gold and green are the best colors. A welding shield can help you avoid heat buildup, which can impact the quality of your welds!

The higher melting point and the lack of reaction with the material are both benefits of this material. However, there are some factors that affect which welder should use them for welding this type of metal – like their preferences or what they’re working on at any given time!

What color tungsten is best for stainless?

If you are looking for something that is less visible, black tightsens are typically recommended. Green can also be a good option because it blends in better with certain clothing and under different lighting conditions.

For the best possible visibility, you can get tungsten in a bright white color. However, this can be more difficult to see against some darker metals, so it’s not always the best choice.

Can you use purple tungsten for stainless steel?

Purple tungsten carbides are some of the hardest and most durable materials out there, so they’re perfect for tough jobs like machining stainless steel. Another benefit of buying an impact driver is that it has a higher resistance to wear-and tear than other types of drivers. This means you’ll get a longer life from your tool!

What is 2% Lanthanated tungsten used for?

It produces less welding fumes than other types of tungsten, making it a safer option for welders. It can be worked on at greater temperatures without turning into harmful fumes. This makes it safer for enclosed spaces like your kitchen, where you might be cooking dinner.

What TIG rod is used for stainless steel?

The two most common types of TIG welding rods for stainless steel are ferritic and austenitic.

Ferritic stainless steel is less expensive than austenitic stainless steel and is better for welding at lower temperatures.

Austenitic stainless steel is more expensive but can be welded at higher temperatures.

Both types of saws have their pros and cons, which depend on the material you are cutting. It is important to know which type of saw is best for each situation before making your purchase decision.

Useful Video: TFS: Battle of the Tungsten Colors

Conclusion

Conclusion paragraph: So, what’s the best tungsten electrode for your application? Hopefully, this article has helped you narrow it down. Keep in mind that the ideal tungsten size and type will vary depending on the welding process and material being welded. If you still aren’t sure which electrode is right for you, or if you have any other questions about welding supplies or techniques, don’t hesitate to contact us. We are always happy to help our customers find the perfect products for their needs. Do you have any tips for choosing the best accordion bags?

References:

- https://www.amazon.com/Welding-Tungsten-Electrodes-Thoriated-10-Pack/dp/B013KZNLGG

- https://www.amazon.com/WeldingCity-Premium-Tungsten-Electrode-Lanthanated/dp/B007TNTRQO

- https://www.amazon.com/Welding-Tungsten-Electrodes-Green-10-Pack/dp/B013KZTNT0

- https://www.amazon.com/Welding-Tungsten-Electrodes-Lanthanated-10-Pack/dp/B013KV8EIK

- https://www.amazon.com/GYS-Tungsten-Electrodes-Stainless-045330/dp/B00G58KRPE

- https://www.weldstar.com/blog/tips-selecting-tungsten-electrodes/

- https://www.weldingempire.com/tungsten-electrodes/#:~:text=We%20recommend%20that%20beginners%20work,%2F32%202%25%20lanthanated%20tungsten.

- https://weldingleader.com/what-size-tungsten-is-ideal-for-tig-welding/