Choose the Best Tungsten for Tig Welding Mild Steel

Customer’s Choice: the Best Rated Tungsten for Tig Welding Mild Steel

38 users answered this survey. Please help us improve this review!

TIG welding is one of the most popular methods for joining mild steel because it can be done with a low cost and availability. This article discusses the different types of tungsten and provides tips on how to select the right one for you.

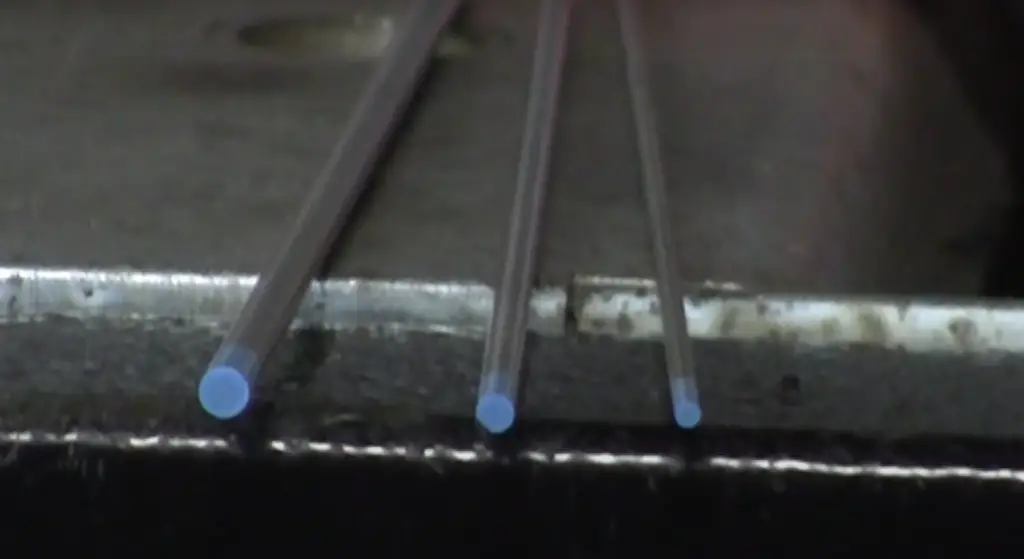

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Blue)

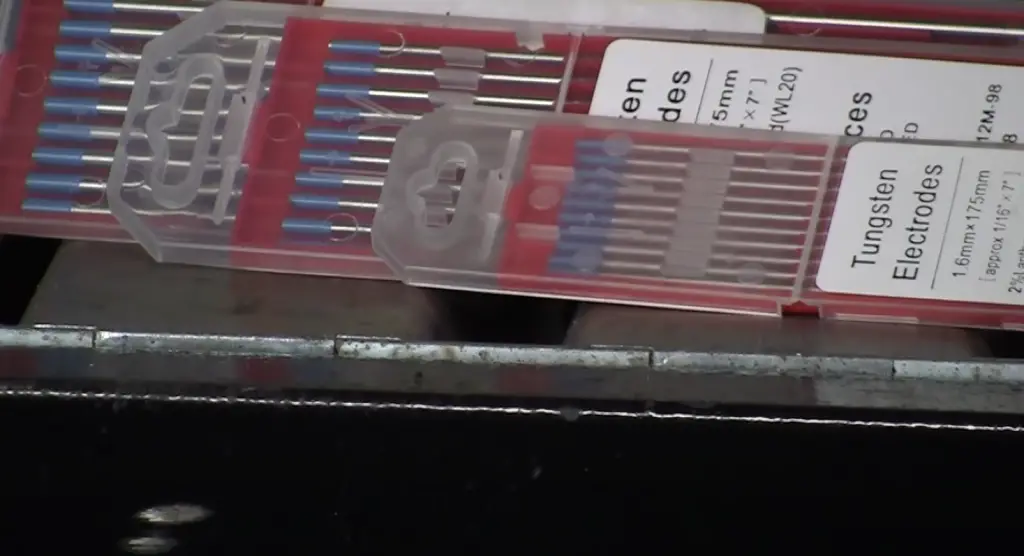

The best tungsten electrodes for Tig welding mild steel have a low working temperature and good arc stability. They’re made by one of the most well-known companies in this industry with high quality products. The electrodes come in boxes so you can see that they are built tough.

The best tungsten electrodes for Tig welding mild steel have a low working temperature and good arc stability. They’re made by one of the most well-known companies in this industry with high quality products. The electrodes come in boxes so you can see that they are built tough.

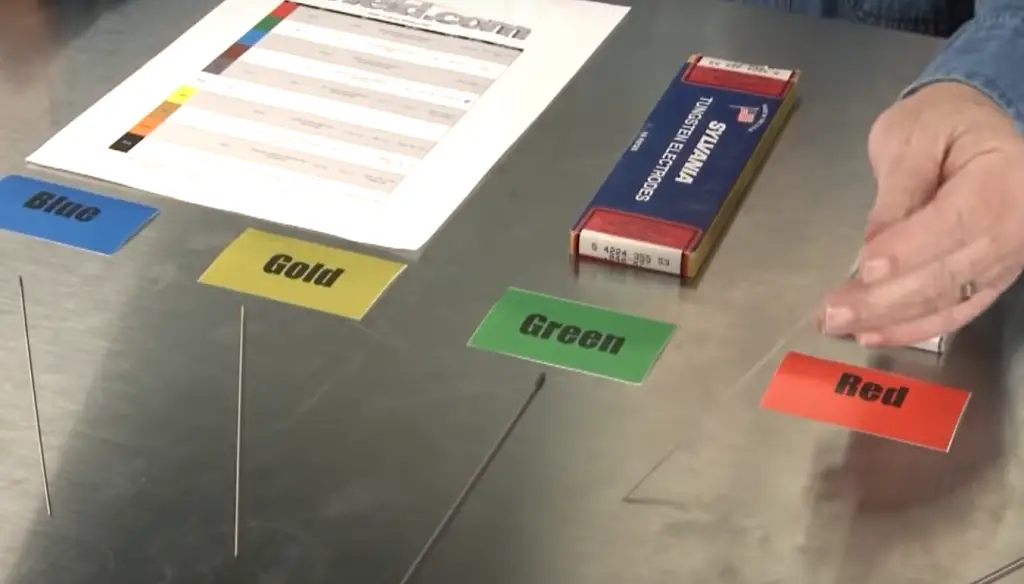

These tungsten electrodes are perfect for welding in all positions, so you can use them for Tig welding mild steel no matter what position it’s in. They’re also color coded according to international standards, which makes life a little easier when you’re trying to figure out which setting to use.

Be careful when using this product because the paint on its end can melt too easily and make a mess. However, if you follow these instructions carefully it will give good results from your TIG welder. [1]

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Red)

TIG welding with these tungsten electrodes is the perfect way to weld mild steel. These red thorium metal rods will offer your welder protection from arcs and are three inches long – perfect for any welding task! These cheap tools come pre-filled so you don’t have to worry about running out of ink anytime soon.

TIG welding with these tungsten electrodes is the perfect way to weld mild steel. These red thorium metal rods will offer your welder protection from arcs and are three inches long – perfect for any welding task! These cheap tools come pre-filled so you don’t have to worry about running out of ink anytime soon.

If you need a quality welding electrode that is affordable, Midwest TIG Welding Sticks is the best choice. [2]

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Gray)

These tungsten electrodes are ideal for TIG welding of mild steel and stainless steel. The electrodes are made of gray ceriated tungsten, which is a good all-purpose material for TIG welding. The package includes ten electrodes, each of which is one-sixteenth inch in diameter.

These tungsten electrodes are ideal for TIG welding of mild steel and stainless steel. The electrodes are made of gray ceriated tungsten, which is a good all-purpose material for TIG welding. The package includes ten electrodes, each of which is one-sixteenth inch in diameter.

They have been proven time and again as the best welding rod for a variety of different materials, from aluminum alloys to magnesium. In addition they adhere strictly by American Welding Society standards so you know your work will be in top condition!

Unfortunately, they’re not designed for use at 175-225 amps. The paint on the end of them melts easily and you’ll have a hard time getting good results from your TIG welder if that’s what you choose to use it with. [3]

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Gold)

These gold-colored rods help keep your workpiece clean. They will help keep the molten metal from getting contaminated. You can’t go wrong when using these rods! They come in small sizes that are easy to control and give precise results. You don’t have to guess how much stick out or filet you need anymore!

These gold-colored rods help keep your workpiece clean. They will help keep the molten metal from getting contaminated. You can’t go wrong when using these rods! They come in small sizes that are easy to control and give precise results. You don’t have to guess how much stick out or filet you need anymore!

These electrodes are the highest rated and most reviewed on Amazon, so you know you can trust their reliability and consistent performance.

This 10-pack of tungsten electrodes is good for welding different types of metals. They work with both AC and DC applications, so they’re perfect for any welding project – whether you’re a beginner, intermediate, or professional welder. You can use them to weld aluminum alloys, magnesium alloys, nickel alloys.[4]

Midwest Tungsten Service TIG Welding Tungsten Electrodes 10-Pack (Gray – 2% Ceriated Tungsten)

These are some of the best tungsten electrodes for TIG welding mild steel that you can find on the market. They are made of gray, ceriated tungsten. They have a diameter of 0.040 inches and come in a pack of ten.

These are some of the best tungsten electrodes for TIG welding mild steel that you can find on the market. They are made of gray, ceriated tungsten. They have a diameter of 0.040 inches and come in a pack of ten.

If you need a TIG welding electrode that is reliable and consistent, Midwest Tungsten has the perfect option for you.These electrodes have high ratings and reviews on Amazon, so you can be sure that you are getting a quality product. They’re also perfect for beginner, intermediate, and professional welders alike.

These electrodes can be used for both AC and DC applications. They are great for welding aluminum alloys, magnesium alloys, nickel alloys, copper alloys, titanium alloys, low-alloyed steels, and non-corroding steels. [5]

Buyer’s Guide

How It Works

Tungsten’s melting point is very high. It is used for welding tough or thick metal. Not only that, but this does not react with other elements, which means you won’t have any problems during your project!

Tungsten can be ground down to create points, which are very sharp. When you heat up the metal with this tailed element, it quickly creates a weld on contact.

Filler Rods for Tig Welding Mild Steel

When you want to weld mild steel with a welder, the right type of filler rod can make all the difference. There are other ways to weld quickly if you don’t have the type of steel that works best. You can use other types of steel, or you can use MIG joints.

These filler rods are designed specifically for welding mild steel, and they will provide you with excellent results. If you can’t find a low-carbon steel rod, you can also use a stainless steel rod. But it won’t work as well as the low-carbon steel rods.If we are welding 16 gauge mild steel, we would choose either 1-6 inches in length or 60/16 inch combination consisting of both ends being this type of machine thinker together with an appropriately sized core.[6]

Why Use TIG for Mild Steel ?

TIG welding is a popular method for joining mild steel. You can achieve high-quality results without much distortion or warping with the right tungsten. This type of work is easy enough that even beginning welders will have no trouble learning how to do it!

There are several types of mig deposition gasses available on the market. Each type has its advantages. It depends on what material it is used with. However, not all gas types work well against every kind of metal source. Make sure you know the strengths and weaknesses of a particular brand or type before investing money into it.

The tungsten should also be easy to work with and not too brittle.Types of Tungsten Electrodes

The tungsten can produce a strong and stable arc. It is easy to start because it has low ionization potentials. All you need to do is add some gas.

Thoriated electrodes have a high ionization potential.

This means that when you use them, there is less chance of an arc not developing and completing your weld faster! They also last longer, so they’ll be ready next time around without having to change out all your equipment like we do with cheaper types such as plain old “tungstens.”

The lower ionization potential of alloy A means it is more difficult to start up than pure metal, and this also causes it to wear out quickly. [7]How to Choose the Right Tungsten

Tungsten provides the best arc stability and weld quality. Pure tungers have been found to work better on thin materials than thorium-based rods. Thorium-based rods are better for working with thicker or rustier metals because they produce more heat. Selecting the right tungsten is a matter of understanding your project and selecting the best rod for the job.

FAQ

What is the difference between red and green tungsten?

Red tungsten is more reactive than green ones. They are better at welding aluminum/magnesium alloys but less stable when working with stainless steel or carbon steels.

Green tungsten is more expensive but it will result in less electrode contamination. Red is a color that has been used for a long time. People have used it for different things, like carpets or jewelry. The color often happens because of years of use. This can sometimes create interesting effects. Welding aluminum and magnesium can be a good way to make your blade; however, you need to be careful near stainless steel because both metals are vulnerable to corrosion.

How do you choose tungsten size?

The size of the tungsten electrode will be based on how densely populated with metal it is. For example, if we are working on thin alloyed steels, a smaller wire can rust-free and keep its integrity. But if our weld joint is thicker than 3/32″ (2mm), then everything changes. For these heavier types of material, we need to use more energy so the weld joint turns out better overall.

You should think about things like the amperage and how long you weld for. You need to choose the size of your welding material based on how thick it needs to be in order to be safe and not break in high winds or when it gets wet. If any of these scenarios apply to you, then you’ll need a tungsten that is at least 12″ long and has an electrode diameter of at least .040″. This will give your weld the necessary strength.

How dangerous is thoriated tungsten?

Thoriated tungsten is a type of metal that can be used in jewelry and sparks. When you wear it, the sun’s UV rays hit this material which makes your piece glow.

Other types of materials might turn dull or lose their shine over time due to corrosion from moisture on skin; if ingested then had adverse effects such as serious digestive problems (can cause vomiting). Keep these materials away from children because they may believe that they are safe to play with, but they are not. If you have any signs or symptoms that may be related to thoriated tungsten exposure, seek medical attention immediately.

What color tungsten is best for mild steel?

There are a few different colors of tungsten that can be used for welding mild steel, but the two most common are green and yellow. The color you choose depends on what you want the weld to look like. Green tungsten is known for being more stable, while yellow tungsten is typically easier to start with.

If you’re just starting out, yellow tungsten is probably the best option. As you gain more experience, you may want to experiment with green tungsten to see if it gives you better results.

Make sure the tungsten is clean before welding. Any dirt or debris can cause problems with the weld.

What color tungsten is for what?

There are different colors of tungsten that exist and each has a specific purpose. The most common colors are green, yellow, brown, and gray. Green is used for general-purpose welding, yellow is used for stainless steel welding, brown is used for cast iron welding, and gray is used for aluminum welding.

The color of tungsten you choose is important because it will determine how well your welds turn out. If you use the wrong color, your welds may not be as strong or may not look as good.

- Green: General-purpose welding.

- Yellow: Stainless steel welding.

- Brown: Cast iron welding.

What is E3 tungsten used for?

E-Series tungsten electrode is used to weld carbon steel, stainless steel and nickel alloys. E-series has a low ionization potential, which makes it ideal for AC welding. It also works well in DC welding applications.

E-series tungsten electrodes are available in many different sizes and shapes. The most common are:

- E-WL-15 (red)

- E-WL-20 (green)

- E-WL-25 (blue)

The “E” stands for electrode. The number following the “E” denotes the % of lanthanum oxide present in the electrode. For example, an E-WL-15 electrode has 15% lanthanum oxide.

The “WL” stands for welding lanthanum. The number following the “WL” denotes the % of thorium oxide present in the electrode. For example, an E-WL-15 electrode has 0.80% thorium oxide.

Lanthanum and thorium oxides are used to increase the arc stability of the electrode. They also help to reduce welding spatter.

How do you pick tungsten?

Picking the right tungsten for welding can be tricky, but there are some key factors you need to consider.

The first thing you need to know is what type of metal you are using. Different metals have different densities, so you need to use different amounts of amperage depending on the metal. For example, thicker metals require more current.

When choosing a welding type, think about the thickness of the materials you will be welding. Thin materials can be welded with a lower-powered welder, while thicker materials will require a more powerful welder.

Useful Video: TIG Welding Mild Steel

Conclusion

Mild steel can be welded with a TIG welder by using the right type of tungsten electrode. The most important thing to remember is that you must use the correct filler rods for the job. Make sure to experiment with different types of electrodes and rods to find what works best for you. With a little practice, you’ll be able to create beautiful welds on mild steel using a TIG welder.

References:

- https://www.amazon.com/Welding-Tungsten-Electrodes-Lanthanated-10-Pack/dp/B013KZ2BIA

- https://www.amazon.com/Welding-Tungsten-Electrodes-Thoriated-10-Pack/dp/B013KZLBGI

- https://www.amazon.com/Welding-Tungsten-Electrodes-Ceriated-10-Pack/dp/B013KWPFR2

- https://www.amazon.com/Welding-Tungsten-Electrodes-Lanthanated-10-Pack/dp/B013KUSWYM

- https://www.amazon.com/Welding-Tungsten-Electrodes-Ceriated-10-Pack/dp/B07946N5P1

- https://weldguru.com/tig-filler-rods/

- https://www.jasic.co.uk/post/tig-tungsten-electrode-types