If you are fond of doing DIY projects at home or you work with metal, you definitely understand how difficult cutting corrugated metal may be. It requires a lot of patience, skills, and techniques. However, with the right tools, it can be done with ease. In this blog post, we will be sharing some tips and tricks that you need to know to work with corrugated metal like a pro. Whether you are a DIY enthusiast or a professional, this guide is for you.

TOP 3 Best Ways of Cutting Corrugated Metal

The first and most important step in working with corrugated metal is to choose the suitable tools. Top 3 of them are a circular saw, snips, and an angle grinder. Before starting to work with the corrugated metal sheet, it is essential to clean the surface thoroughly, removing any dirt or debris that could interfere with the machine’s functioning. You will also want to use the right cutting blade for the project.

Cutting with a circular saw

After you have installed the circular saw, it’s time to start cutting the corrugated metal. You should rest the metal sheet on a sturdy and flat surface, and secure it tightly with clamps to prevent it from moving. Use a steady hand to run the saw through the marked line, using moderate pressure to push the blade through the metal, and don’t force it too hard.When you’re working with a circular saw, safety should be a top priority. You should not forget about necessary personal protective gear, for example a dust mask and safety glasses. It is important to ensure that the blade is sharp enough and properly installed before beginning to cut. Also, keep your fingers away from the blade, and avoid cutting in wet conditions to maintain optimum safety.

Cutting with Snips

The first step in working with corrugated metal with snips is selecting the right type of snips. They can be of different sizes, shapes and designs, and it is essential to choose the most suitable ones for the job. There are three types of snips that you can use: straight-cut, left-cut, and right-cut. The straight-cut ones are the most popular type and are ideal if you need to cut a straight line. However, left-cut and right-cut snips are a perfect choice if you need to cut curves or angles.

It can sometimes be dangerous to cut corrugated metal, especially if you do not observe safety precautions. Wear protective clothing, such as gloves, goggles, and ear protection, to avoid injury from metal shards or noise. When using snips, hold them securely and do not place your hands near the cutting edge. Also, ensure that you dispose of the waste metal safely to avoid injuring yourself or others.

Cutting with an angle grinder

When you are cutting corrugated metal with the help of an angle grinder, it’s important to use the right technique. Start by positioning the blade near the edge of the metal, then slowly angle it into the metal. As you cut, keep the angle grinder moving steadily and don’t apply too much pressure. This action will not let the blade get stuck or overheat.[2]

How to Cut Corrugated Roofing: Handy Tips

Installing corrugated roofing panels is a great chance to add extra protection and aesthetic charm to your home. At first it may seem intimidating, but cutting corrugated roofing panels is easier than it looks, just try to use the following advice!

Step 1: Before cutting your corrugated roofing panel, you must measure and mark the panel correctly. Ensuring that your measurements are accurate will prevent you from wasting material.

Step 2:Use a measuring tape to mark your panel with chalk or other marking tools. This step will also make the cut clean and exact.

Step 3: When you start cutting, always follow the marked lines, move the saw or cutting tool slowly and gently, and avoid too much pressure on the sheet. This will help you get a perfect cut without damaging the panel’s corrugated shape.

Step 4: Always cut away from your body and wear safety gear to prevent injuries. Even if you have created a clean cut, there may still be some rough or sharp edges. You can smooth out these edges by using a metal file. This step will make sure that there are no rough edges that can cause injury, and it will improve the final result by making it look professional.

Ways to Cut Corrugated Metal Roofing Panels

Installing a corrugated metal roof on your home or shed can be a great way to upgrade your property’s exterior. However, cutting such roofing panels can be a daunting task. From the jagged edges to the potential for injury, you want to make sure you are taking the proper precautions.[1]

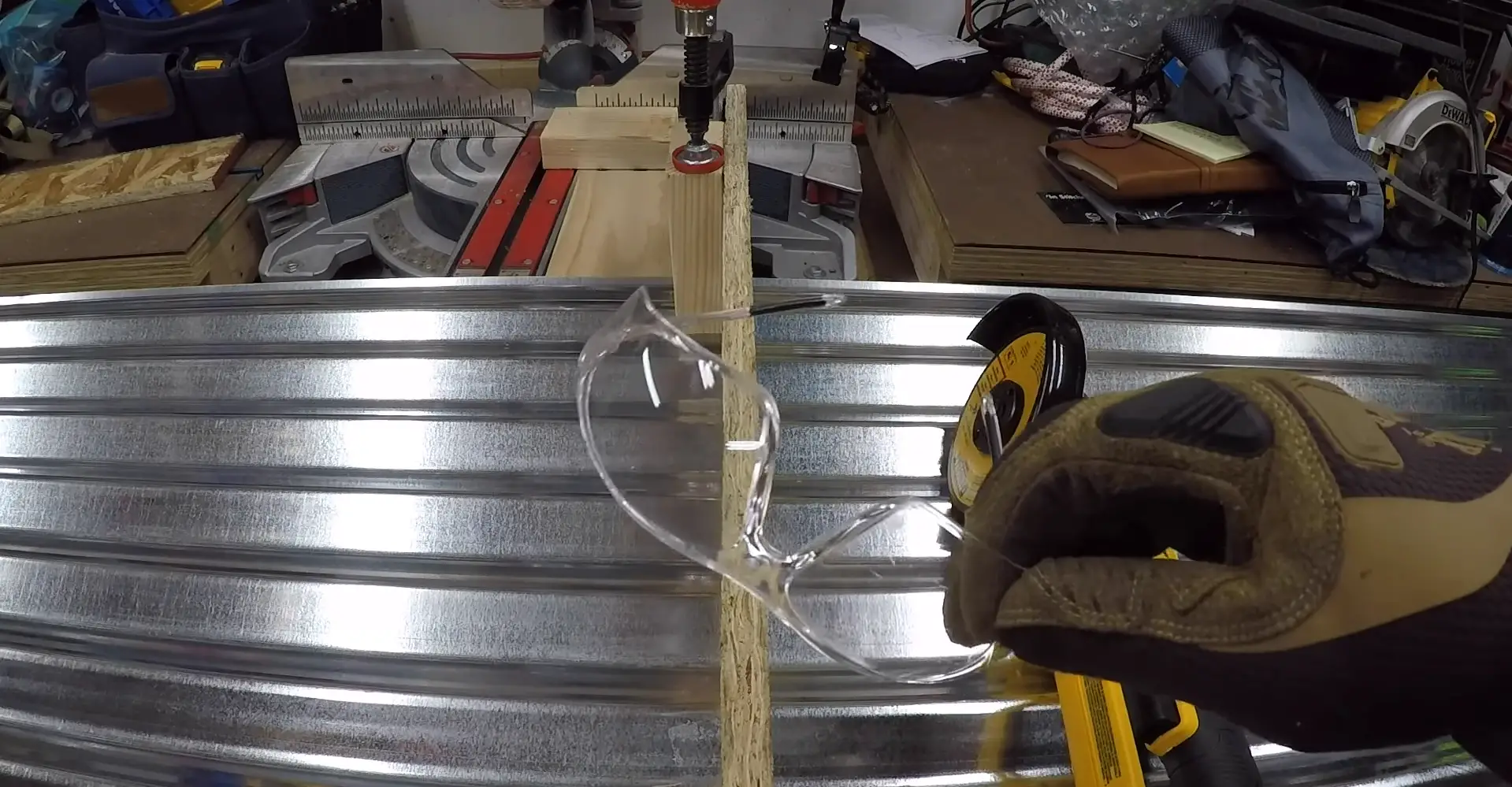

Step 1: Prepare the Safety Equipment

Before starting, check whether you have prepared all the necessary safety equipment. It’s essential to have a pair of heavy-duty work gloves to protect your hands from cuts and scrapes. Wear a dust mask to avoid inhaling shards of metal while cutting, as well as safety glasses with side shields to protect your eyes. Earplugs or earmuffs are also recommended to protect your hearing from the noise created by the cutting process.

Step 2: Leave it to the Professional

Corrugated metal roofing panels can be challenging to cut, especially if you aren’t used to handling metalworking tools. If you’re hesitant about cutting the panels yourself, consider leaving it to the professionals. A contractor specialized in metal roofing can provide you with the highest quality workmanship and ensure the job gets done correctly. [4]

The Perfect Saw to Use When Cutting Corrugated Sheet Metal Roofing

There are a variety of different equipment that can be used for this purpose, but some are more effective than others. You must choose the suitable saw for your project to ensure that you get ideal cuts and do not damage the panels or risk personal injury. So whether you choose an angle grinder, jigsaw, a circular saw, metal cutting shears, or oscillating tool, be sure to use the necessary safety equipment and follow all instructions for your specific tool. [3]

What are Tin Snips?

Tin Snips are the tool, suitable for cutting metal sheets, which are soft and thin, like aluminum or copper. If you have a small project, this tool could be the right choice for you. But, if you need to cut thicker or harder metals or make curved or angled cuts, you should consider other options, for example, compound or aviation snips.

Compound Snips, Tin Snips, and Aviation Snips

Compound Snips are a combination of aviation snips and tin ones, that is why they are a versatile cutting tool suitable for various materials and applications. They feature a compound leverage mechanism that multiplies the cutting force, making them easier and more comfortable to use. With the help of these snips you will be able to cut different kinds of lines: angled, curved or straight, and come in different sizes and shapes. If you want a cutting tool that can handle different tasks and materials, compound snips will be a perfect choice. [4]

Aviation Snips are one of the most common tools for professionals, especially those in the aviation industry. Using these snips you will be able to cut sheet metal, plastics, and any other tough material. They come in three types, straight, left-cutting, and right-cutting.Compared to tin snips, aviation ones have a bit longer blades and their design helps you get exact and clean cuts. Aviation snips are the way to go, if you regularly deal with metal.

Aviation Snips: Color Coding

It is essential to understand the color-coding feature often displayed on the handles of the tools. The colors are not only for aesthetic purposes but they also have practical implications.

The system of color-coding is created to identify the kind of snip and its application specific to the handle. Often blue, green, and red colors are used to indicate the snips for right-cutting, left-cutting, and straight-cutting, respectively. The colors give users the ability to easily understand which tool to use, saving time and reducing the risk of error.

Straight Tin Snips VS Offset Snips?

Straight tin snips are the most popular among all the tin snips. They are called so because their blades are aligned in a straight line. Straight tin snips are created for cutting lines, trimming edges, or making small cuts.

One of the major advantages of this type of snips is the fact that they are really easy to maintain. But they are not ideal for cutting curves or tight angles.

One of the major advantages of offset snips is the fact that with their help you can cut sheet metal accurately. However, as a rule, such snips are more expensive than straight tin snips. They are also heavier and require more effort.

When you have to choose the suitable tin snips, it all comes down to your specific needs. If you’re working on a project that requires straight cuts, straight tin snips are the perfect choice. On the other hand, if curved cuts or cut complicated shapes are needed, then offset snips are the better choice.

It’s important to choose quality snips that are comfortable to use and that are made from durable materials. Cheap snips may be tempting, but they are more likely to break or become dull after a few uses.

Metal-Snipping Techniques and Tips

No matter which type of tin snips you choose, there are some tips you can follow to make your cutting tasks easier and more efficient.

Right-side Up

One of the most common mistakes people make when snipping metal sheets is cutting upside down. Snipping the top surface instead of the bottom can cause ragged edges or distortions, making the final product appear unprofessional. Therefore, before starting, ensure that the metal sheet’s surface with the finish or cleanest side faces upwards.

Consistency Matters

Consistency is vital when snipping metal, and this means that you shouldn’t stop and start while cutting. Snip continuously to maintain the same thickness and edge throughout the whole cut. Additionally, take your time to avoid any twisting or buckling of the metal. You can use clamps to keep it stable, especially when dealing with a large metal sheet.

Shorter Cuts are Better

When snipping metal, it is best to work with shorter cuts rather than long cuts. This is because short snips offer better control of the direction and the blade’s pressure. If you need to cut a long edge, mark the cut line and divide it into smaller sections, then work on each section individually. This makes it easier to snip the metal sheet without bending or distorting it.

Use the Best Snip

There are different types of Snips, each designed for a specific type of metal sheet. Choosing the best Snips for the task at hand makes snipping metal sheets a lot easier. For instance, if you are working on thin metal sheets of up to 24 gauge, then the straight Snips are best. Curved Snips, on the other hand, are more suitable for thicker metals since they provide better leverage and pressure control.

Alternate between Snips for Straighter Long Cuts

When snipping long metal sheets, alternate between straight Snips and curved Snips intermittently. This helps to maintain straightness in the length of the sheet and reduce bending or twisting. By alternating Snips, you can make progress more efficiently since you can use the best tool for any given cutting segment.

Make Rough Cuts and Finishing Cuts

When learning how to snip metal, it is essential to understand that making rough cuts is a crucial step. Rough cuts are not meant to provide a perfect edge, but rather just enough of a cut to reduce metal sheet size closer to the intended final size. Once all rough cuts are made, you should go back and make finishing cuts to achieve precision and clean edges.

Don’t Strain on Heavy Metals

To snip metal appropriately, you need to have the right tool for the job. It may be tempting to use your household scissors or wire cutters to snip metals, but this can lead to broken or dull blades. Different metals have various thickness levels called gauges. Gauge is essential to consider because the thickness of the metal affects how quickly and how easily it gets snipped. Thicker metals sheets might require more force and pressure to cut through, while thinner ones will be easier to snip. Understanding the thickness of the material sheet will help you choose the ideal snipper blades or scissors to use.

Metal is Forgiving

Snipping metal sheets takes practice. If you are just starting, it might take you some time before you master the techniques involved. Do not get discouraged if it takes you more than one trial to achieve a clean snip. Starting with small projects as you work your way to the larger ones gives you motivation and confidence to pursue more complicated projects later.

Practice Makes Perfect

Cutting corrugated metal requires some practice to get it right. It gets easier through time once you master the techniques. Hence when starting on a project, consider doing some cuts with extra material to understand how the tools operate before engaging on the metal sheet.

FAQ

What is the best tool to cut corrugated metal?

The best tool for the job will depend on the thickness of the metal and the shape of the cuts you need to make.

If you’re working with thin sheet metal, tin snips are probably your best bet. They’re affordable, easy to use, and can make straight or curved cuts. For thicker metal or more complex shapes, a jigsaw or circular saw might be a better choice. These tools can make precise cuts quickly and easily. And if you need to make cuts in tight spaces or irregular shapes, an angle grinder with a metal-cutting blade is your best bet. It’s powerful, versatile, and can make quick work of even the toughest cuts.

How do you cut corrugated metal roofing sheets?

If you’re using tin snips, simply follow the lines you marked and cut along the metal’s corrugations. For jigsaws and circular saws, be sure to use a metal-cutting blade, and follow the lines you marked as closely as possible.

How do you cut corrugated metal with a grinder?

If you’re using an angle grinder, clamp the metal down securely and use the grinder to make your cuts. Be sure to work slowly and carefully, and wear earplugs and a face shield to protect yourself from sparks.

Is corrugated metal easy to cut?

Cutting corrugated metal can be a challenge, but with the right tools and techniques, it’s a manageable task. Whether you’re using tin snips, a saw, or an angle grinder, be sure to wear protective gear and work slowly and carefully to ensure a clean, precise cut.

What is the best tool to cut metal by hand?

There are several hand tools available for cutting metal, and the best one for you entirely depends on the thickness of metal you’re trying to cut, the level of precision you need, and the price you’re willing to pay.

Is it OK to cut metal roofing with a grinder?

Cutting metal roofing with an angle grinder is an efficient and convenient method, especially for hard-to-reach areas and different types of roofing materials. However, safety should always come first when using this tool. Always wear protective gear, work in a well-ventilated area, and observe safety precautions.

Can I use an angle grinder to cut sheet metal?

The cutting of metal roofing is essential not only for installation but also for repairs, maintenance, and re-roofing. One of the cutting methods being utilized by professionals and DIYers is by using an angle grinder. A grinder can be used to cut different types of metal roofing materials like, corrugated metal, standing seam, ribbed panels, and others. You can also switch between grinding and cutting discs depending on the roofing job.

Useful Video: Cutting corrugated metal roofing with an grinder

Conclusions

Cutting corrugated metal can seem complicated, but with the right tools, technique, and safety precautions, it can be done safely and effectively. Always take careful measurements, choose the right tool for the job, and protect yourself with safety equipment. Whether you’re using tin snips, a saw, or an angle grinder, be sure to wear protective gear and work slowly and carefully to ensure a clean, precise cut. By following these simple steps, you’ll be able to tackle any corrugated metal project with confidence.

The more you practice and perfect your skills, the more likely you will be to cut corrugated metal quickly and efficiently. If you’re unsure about any part of the process, don’t hesitate to seek out advice or ask for help. Remember, taking the time to learn how to cut corrugated metal properly can make all the difference in your next project!

References:

- https://www.jlconline.com/how-to/roofing/cutting-metal-roofing_o

- https://www.wikihow.com/Cut-Corrugated-Metal

- https://www.roofingmegastore.co.uk/blog/how-to-cut-corrugated-roofing.html

- https://howlongdoesrooflast.com/best-way-to-cut-metal-roofing/