Choose the Best Grinding Wheel for Tungsten

Customer’s Choice: the Best Rated Grinding Wheels for Tungsten

187 users answered this survey. Please help us improve this review!

This guide will help you be more creative with your projects. We’ll cover all types of wheel designs and explain how they can improve any workflow or tool application scheme. The wheel designs will help you control accuracy in whatever type(s) of machine/equipment you have available. We can take our protective gear off now. We know which one fits best after reading through these pages carefully.

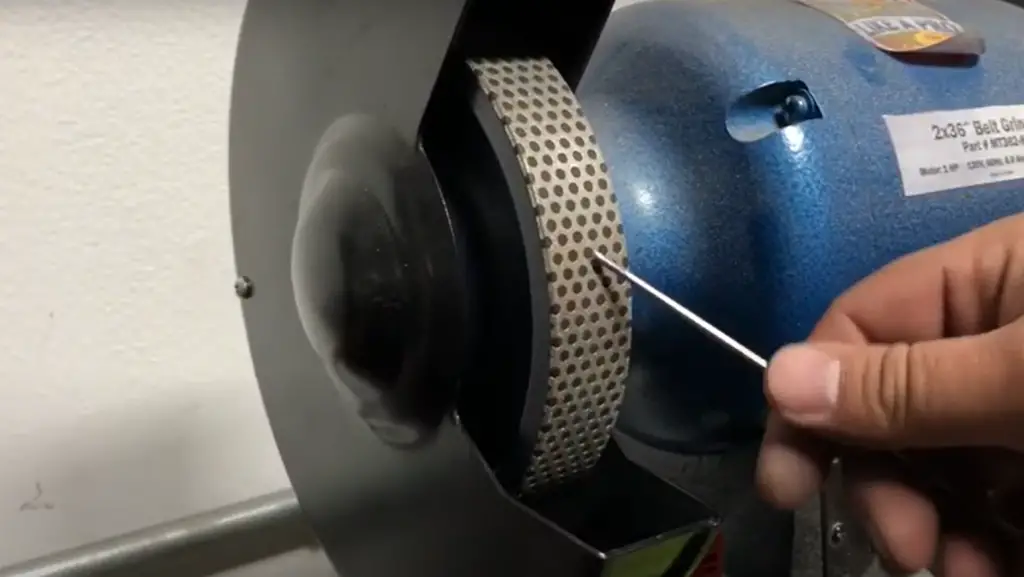

Tungsten Electrode Sharpener Grinder

It is a machine that sharpens your tungsten electrodes. The diamond wheel is used to sharpen the tungsten electrode points.The machine is small, lightweight and easy to use.

It is a machine that sharpens your tungsten electrodes. The diamond wheel is used to sharpen the tungsten electrode points.The machine is small, lightweight and easy to use.

The grinding disks are not very flat, so you’ll experience some vibration and a non-uniform grind. Plus, it doesn’t come with the rotary tool, so you’ll have to buy that separately. [1]

Enkay Diamond Wheel, Carded

This wheel is made of durable diamond-coated steel, so it can stand up to even the toughest materials. The Enkay Diamond Wheel is also carded, so it’s easy to find and purchase.

This wheel is made of durable diamond-coated steel, so it can stand up to even the toughest materials. The Enkay Diamond Wheel is also carded, so it’s easy to find and purchase.

The Enkay Diamond Wheel is a powerful tool that can help you get the job done quickly and efficiently. However, you need to be careful when using it, as disks can explode if you put side loads on them. Additionally, the screw can be too long, so you’ll need to use washers to keep it in place. Finally, be aware that there is no tread inside the wheel, so the screw can slide in and out easily. With these precautions in mind, the Enkay Diamond Wheel is a great tool for those who need it. [2]

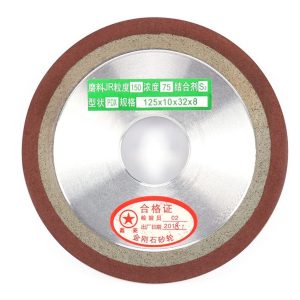

Diamond Grinding Wheel Grinding Circles for Tungsten Steel

This is a perfect choice for anyone who is looking to get into steel milling or sharpening tools. The 320 grit diamond coating is perfect for hard metals. The 25mm bore diameter makes it easy to fit onto most standard grinders.

This is a perfect choice for anyone who is looking to get into steel milling or sharpening tools. The 320 grit diamond coating is perfect for hard metals. The 25mm bore diameter makes it easy to fit onto most standard grinders.

It is designed to be used on hard materials like carbide and steel. It has a concentration of 75%, meaning it will work best on these types of surfaces. This diamond blade is perfect for quickly and easily cutting through hard and brittle carbide. Plus, the friendly design makes it easy to use even for beginners. [3]

Resin diamond wheel for tungsten carbide

This is a good wheel to use if you want the best results when grinding tungsten. The reason for this is that it provides an excellent balance between speed and durability. Additionally, it produces very little dust, meaning that your workspace will stay clean.

This is a good wheel to use if you want the best results when grinding tungsten. The reason for this is that it provides an excellent balance between speed and durability. Additionally, it produces very little dust, meaning that your workspace will stay clean.

This wheel is perfect for sharpening carbide tools. It has a medium grit of 150 and a single tapered design that makes it easy to control and maneuver. Plus, the resin bond ensures durability and a long lifespan. If you want a high-quality, durable diamond grinding wheel, the Resin Bond PDX Resin Diamond Wheel is the perfect option.

The resin diamond wheel is a good option for those looking to get the best results with their tungsten grinding. Just be sure to follow the above tips to ensure that you get the most out of it. [4]

6 inch Resin bond 12V2 flaring cup diamond wheel for tungsten carbide

It is designed for use on carbide and high speed steel, and it can be used wet or dry. This wheel has a diameter of six inches and a thickness of one inch.

It is designed for use on carbide and high speed steel, and it can be used wet or dry. This wheel has a diameter of six inches and a thickness of one inch.

It is perfect for getting a smooth, precise finish on your tungsten carbide projects because it is made of durable aluminum with a resin bond and high-quality diamond abrasive material. Plus, it will not heat up or damage your workpiece like some other grinding methods can. Use this top-of-the-line diamond wheel to get the perfect finish on your next tungsten carbide project! [5]

Buyer’s Guide

What is a grinding wheel?

A grinding wheel is a tool that is used to cut, polish, or grind different materials.

It can be used on things like metal, glass, ceramics, and plastic. There are many types of sandpaper.

The bond type determines the strength of the wheel and how it will be used. There are four types of bonds:

- Vitrified: The strongest and most common bond. It is made by firing a clay-like material in a kiln until it becomes hard like ceramic.

- Resinoid: Made by combining synthetic resins with fillers and then curing them under heat and pressure. They are typically used for high speed applications on metals, stone, glass, or plastics.

- Metal: A weaker bond that is used for low speed applications on ferrous metals.

- Electroplated: The weakest type of bond is used for very delicate work or when the abrasive needs to be constantly replenished (such as when polishing). [6]

What abrasives are available for grinding wheels?

The three types of grinding wheels are silicon carbide, ceramic aluminum oxide, zirconia alumina and aluminum oxide.

Silicon is harder than steel, but it can be used to sharpen hard metals. This is because silicon is a very hard material that can hold an edge well.

Alumina helps to sharpen softer metals like brass or bronze. Its small particles don’t scratch the surface too much before breaking down under pressure. However, if it chips away, water can get into the pores of the metal and cause corrosion over time if it is not protected with a film of oil.

For example, if you are going to grind a hard metal such as steel, you will need a special grinding wheel. You will need to use a harder material than your choice material – in this case, silicon carbide would work perfectly!

Its small particles will not scratch the surface too much before breaking down under pressure. If the metal is not protected with a film of oil, water can get into the pores of the metal and cause corrosion over time.The hardest type of grinding wheel is zirconia. It’s perfect for grinding harder metals like stainless steel or titanium. However, because its particles are larger in size than others, it can cause more surface area damage if not used carefully. [6]

Selecting the right grinding wheel

There are different types of grinding wheel to choose from! Some will sharpen blades, while others can polish your surface cleanly and efficiently.

The following factors should be considered, when choosing a grinder wheel:

- Material

- Size and shape of your object

- Personal preferences

If you’re still not sure which grinding wheel to choose, don’t hesitate to ask for help from a knowledgeable salesperson.

Be sure to follow all of the manufacturer’s instructions carefully. With a little practice, you’ll be able to achieve professional results at home. [6]

Reading the grinding wheel

The first thing you need to do is identify the material you will be working with.

Once you know what material you will be working with, you can start looking at different brands and models of grinding wheels. There are many different manufacturers out there, so it is important to do some research before making your final decision. You should read online reviews and compare prices in order to find the best deal possible.

Grinding wheel specifications can be confusing, but it is important to know what you are looking for. There are a few things you should consider when choosing a grinding wheel:

- The smaller the grit size, the longer your tool will last before you need to sharpen it or replace it.

- The hardness of the stone can determine if there are easier ways to cut it. This includes using less pressure to make the cut, which means that it will be done faster.

- Finally, think about how fast you want to go. Remember that anything faster than could cause some problems.

FAQ

How do you grind tungsten?

To get the best results when grinding tungsten, use a diamond wheel on your angle grinder. You will remove material quickly in such a way. Keep the iron at 15 degrees and move it back and forth with light pressure. Use two hands if needed. When using bench-based power tools, like grinders or drill presses, hold onto both pieces of metal so they don’t move. Apply just enough pressure for each individual task and then move to the next section. You should always be careful to avoid getting anything caught up beneath one edge of the tool.

Does it matter how you sharpen tungsten?

If you use the wrong wheel for your tungsten, you will face serious consequences. If you’re not careful, you could end up with welding defects or even explosions. If you are going to use a grinding tool, make sure that it is designed for tugs.

It’s easy to forget how dangerous it would be if we were using the wrong type of grinder when working with highly volatile substances like gasoline. If we were to use the wrong grinder, we could end up getting injured from things like burns.

Do I need a tungsten grinder?

Tungsten Grinders are an essential part of the process for working with tungstens. The grinding blades help to maintain the lifespan of the appliance and make it more convenient for you. This is not just true for this instance, but for other instances as well.

Tungsten is one of the hardest metals in existence, making it difficult to work with. A good quality tinger grinder can help you quickly sharpen and point your electrodes, saving you time!

When choosing between a desktop or hand held tungsten grinder, there are many things to consider. The type of power source you need depends on where and when you will use it most often. If you only need it for your home, an AC model would work well. But if you want more freedom, choose a model with battery capabilities. That way, you can charge it up anywhere without worrying about cords getting in the way.

There are two main types of metal mesh used in making grinders, expanded and unexpanded. The difference between these styles is that an expandable wheel can be reshaped to fit any curve or surface pattern easily. A fixed solid piece will never change its shape no matter how much pressure you put against it. This is because it doesn’t have anything holding the strands together except themselves alone. If someone wants something flat, they must choose between granite stones instead.

Tungsten grinding is an art that requires patience and finesse. You should consider what power source or type of wheel will work for tungsten in the long run to see if they meet your needs.

Can tungsten get contaminated from grinding it?

Tungsten is a popular bead-metal for commercial grinder applications because it attracts and holds onto iron particles. If you are using the wrong type of wheel or contaminated grinding material, then your tungsten may become stained with other metals like steel. This can cause clogging in machinery – never underestimate how important maintaining quality control on equipment is!

Tungsten is a type of metal that can be ground and polished to create jewelry, tools, and other objects. There is no one definitive answer to this question. It depends on what you are trying to make and your personal preference.

What will grind tungsten carbide?

Tungsten carbide is a very hard material that can be difficult to grind. However, diamond and cubic boron nitride (CBN) grinding wheels can be used to do the job. There are two types of accessories that are more expensive than other options, but they last much longer. This means you won’t need to buy new ones as often, which makes them worth considering for many people.

Tungsten carbide is a good material for making sharp tools because it can withstand higher temperatures than other metals. This means that it will stay sharper for longer and is less likely to break.

Abrasive cutoff wheels are a good choice for this type, but be aware that you will produce a lot of dust! Make sure to wear protective gear like gloves or a facemask when working with them so you don’t get injured.

Bonded abrasives are better than live stones because they can cut quickly. They can also last longer if used correctly.

Always read and follow the instructions carefully. Make sure you understand what is safe to do. To get the most out of this tool or any other tool in your garden, you need to know how to use it correctly.

Useful Video: Best Grinding Wheel!

Conclusion

A grinding wheel is a tool that can be used to shape and smooth metals. You should choose the right abrasive for the job. Grinding tungsten can be difficult but with the right tools and techniques it can be done quickly and easily.

The best type of grinding wheel for tungsten is an expanded metal grinding wheel. These wheels are made with a very fine mesh that will not get clogged up with tungsten. The crucible is also able to withstand the high temperatures that are generated when grinding tungsten.

When choosing a brand, it is important to read reviews and compare prices. Make sure that the wheel you choose is rated for the speed of your grinder.

References:

- https://www.amazon.com/ALUMINUM-Electrode-Sharpener-Multi-Angle-Connecting/dp/B07VWQ5553/

- https://www.amazon.com/Enkay-387-3C-3-Inch-Diamond-4-Inch/dp/B00CP628XO/

- https://www.amazon.com/Grinding-Wheel-Tungsten-Sharpener-Accessories/dp/B07DCJGJ74

- https://www.amazon.com/diamond-tungsten-carbide-grinding-Dia100Hole16mm/dp/B075ZQRTV3

- https://www.amazon.com/flaring-tungsten-grinding-sharpening-Dia150hole32/dp/B0761G9GY2

- https://www.nortonabrasives.com/en-gb/resources/expertise/which-grinding-wheel-should-i-choose