Non-ferrous metals encompass a diverse range of metallic elements that do not contain a significant amount of iron, unlike steel and iron themselves. These metals possess distinctive characteristics such as lightweight composition, high conductivity, non-magnetic properties, and exceptional resistance to corrosion. These unique properties make these metals highly desirable and well-suited for various applications across industries including aerospace, construction, and electronics. In this comprehensive document, we will delve deep into the fascinating realm of it, exploring their intricate properties, different types, versatile uses, and much more. Get ready to embark on an enlightening journey through the captivating world of these amazing metals!

Non-Ferrous Metals in Ancient History

Non-ferrous metals have played a significant and fascinating role throughout human history. Copper, a versatile non-ferrous metal, captured the attention of early civilizations due to its remarkable malleability and abundance in nature. This exceptional metal, widely accessible and easily shaped, became the earliest material to be utilized by humans, sparking a revolution in craftsmanship and innovation.

The Bronze Age, aptly named after the Copper alloy Bronze, is evidence of the profound impact of base metals on the transformation of human society. The emergence of bronze, a groundbreaking fusion of copper and tin, revolutionized the manufacturing of tools, weapons, and artwork. It propelled societies forward, igniting a new era of progress and ingenuity that forever altered the course of history.

In addition to Copper, another non-ferrous metal that holds a place of prominence is Gold. This precious metal not only mesmerized ancient cultures with its captivating beauty but also held practical and symbolic significance. Gold adorned not only the bodies of the elite in exquisite jewelry and ornate decorations but also served as a medium of exchange, a form of currency that facilitated trade and commerce. Its allure and timeless allure continue to captivate us to this day.

The use of these remarkable non-ferrous metals in ancient times laid the foundation for the development of advanced metallurgical techniques, pushing the boundaries of human knowledge and craftsmanship. These early pioneers set the stage for the remarkable technological advancements and achievements that we marvel at in the modern world. The legacy of non-ferrous metals lives on, forever intertwined with our progress as a society.[1]

Non-Ferrous Metals and Casting

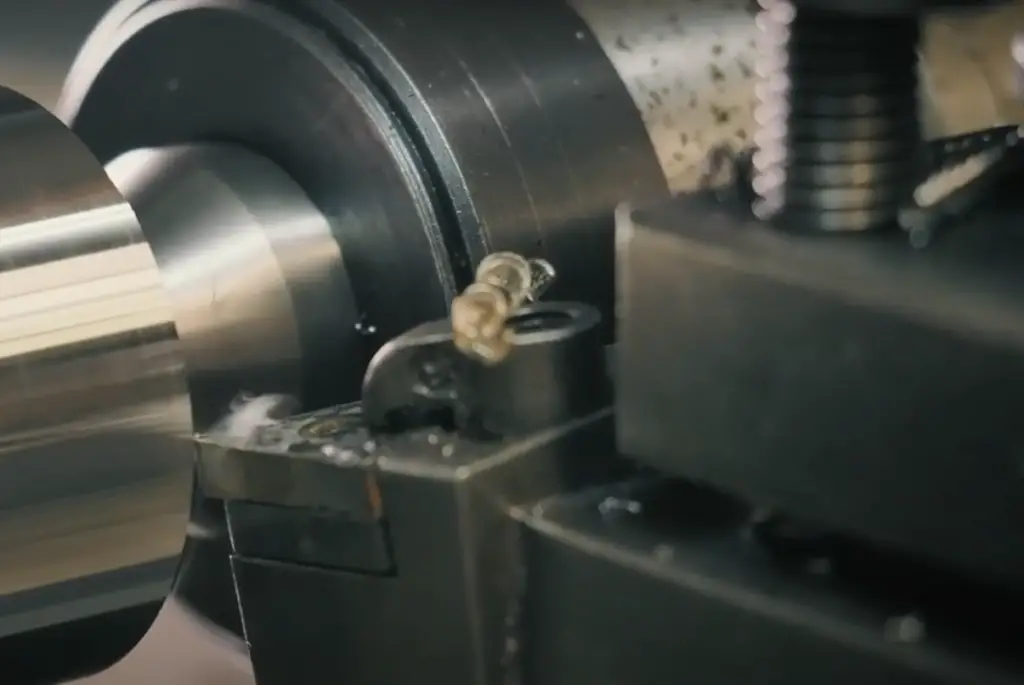

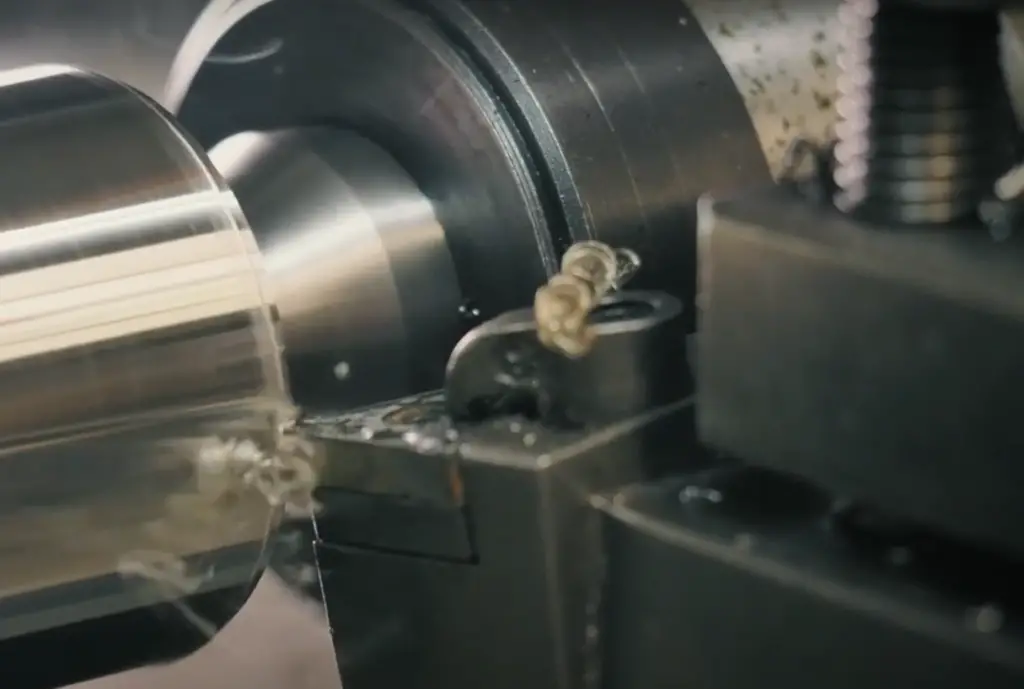

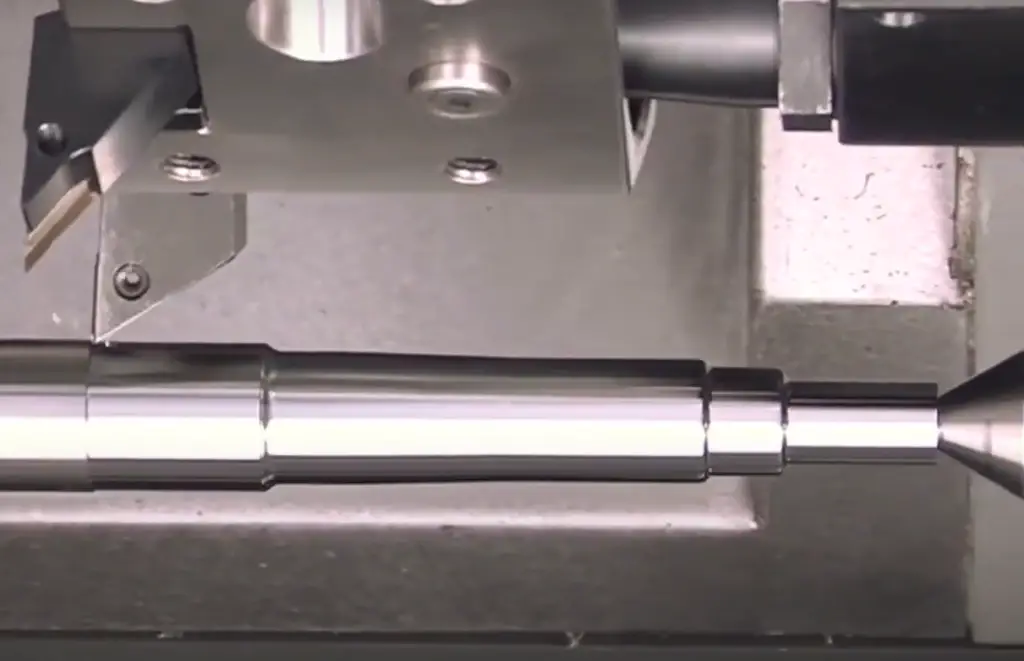

Casting is a fascinating and intricate manufacturing process that involves pouring liquid metal, such as Aluminum, Zinc, or Copper-based alloys, into a precisely designed mold. This form includes a precisely formed hollow cavity that enables the metal to flow and fill each intricate part. As the metal cools and solidifies, a solidified part, known as a casting, takes shape within the mold.

Base metals, famous for having unique properties, play a crucial role in the casting process. Take Aluminum, for example. Its lightness and outstanding anti-corrosion characteristics provide it with the best possible match for a large variety of uses, including automotive parts and aircraft components. On the other hand, zinc, with its excellent durability, is commonly used in die casting to create precision parts.

Furthermore, Copper-based alloys, renowned for their superior thermal conductivity, find extensive use in the casting of heat exchangers and boiler parts, ensuring efficient heat transfer.

The versatility and importance of metals in casting applications cannot be overstated. Their diverse qualities and broad range of potential uses make them indispensable in the ever-evolving manufacturing sector.[2]

Common Non-Ferrous Metals and Alloys

There is a wide variety of colored metals and grades of alloys that find applications across diverse industries. From lightweight Aluminum, commonly used in aerospace and automotive sectors, to corrosion-resistant Titanium, employed in medical and marine applications has special characteristics that render it fit for specific purposes.

The versatility and unique characteristics of these base alloys contribute to their widespread use and importance in various industrial sectors.

Copper

Copper is among the primary steels discovered and utilized by humans thousands of years ago, and continues to play a critical role in modern society as a crucial non-ferrous metal. Its remarkable reddish-brown color not only distinguishes it but also adds to its aesthetic appeal. Noted for its outstanding electrical conductivity, Copper remains a preferred choice for electrical wiring and a wide range of electronic devices, ensuring efficient power transmission and conductivity.

However, its significance goes beyond its electrical applications. Copper’s outstanding thermal conductivity, corrosion resistance, and remarkable malleability make it an ideal material for various heating and cooling systems, plumbing installations, and intricate metalwork projects. Its versatility is truly remarkable.

Interestingly, Copper also possesses antimicrobial properties, making it a valuable component in healthcare settings where reducing the risk of bacterial contamination is crucial. This unique attribute further amplifies its importance in safeguarding public health.

Moreover, Copper alloys, such as bronze and brass, expand the scope of its applications. From musical instruments that produce enchanting melodies to sturdy marine hardware that withstands the harsh conditions of the sea, copper alloys exhibit exceptional strength and durability. Additionally, these alloys are extensively used in crafting ornamental pieces, adding a touch of elegance to our surroundings.

As we continue to innovate and evolve, the role of copper in our technological and industrial landscapes remains paramount. Its diverse properties and applications make it an indispensable material that contributes to the advancement and progress of various sectors, from electronics to construction.

Aluminium

Aluminium, the third most abundant element on Earth, is a versatile non-ferrous metal that plays a significant role across various industries. With its silvery-white appearance and exceptional resistance to corrosion, Aluminium possesses both aesthetic appeal and durability, making it suitable for a wide array of applications. Its remarkable lightweight nature, coupled with its strength, positions it as the preferred choice in sectors such as aerospace and automotive, where reducing weight is critical for enhancing fuel efficiency. Furthermore, this metal boasts excellent thermal and electrical conductivity, second only to Copper, making it an indispensable component in electrical transmission lines. The malleability of Aluminium allows it to be easily worked into thin sheets, serving multiple purposes ranging from beverage cans to foil packaging. Notably, the recyclability of this metal adds another layer of value, as it can be recycled without compromising its original properties, thus contributing to a more sustainable and resource-efficient world. The versatility, durability, and recyclability of Aluminium make it an essential material that shapes industries and fosters a greener future.

Lead

Lead is a heavy, malleable, and ductile metal that has been used by humans for thousands of years. It is widely recognized for its bluish-white color when freshly cut, but gradually tarnishes to a dull grayish hue upon exposure to air. This versatile element, known for its high density and low melting point, finds its primary application in the production of batteries, especially automotive batteries.

Moreover, due to its exceptional sound absorption properties, Lead is commonly utilized in the construction of sound barriers, ensuring a peaceful environment. In addition, its capability to provide effective shielding against radiation in medical and scientific facilities makes it a valuable protective material.

Despite its numerous uses, it is crucial to note that it is toxic and can have severe health consequences if not handled properly. In recent years, there has been a significant focus on reducing lead usage and exploring safer alternatives, particularly in residential and consumer products. However, it is worth mentioning that in certain industrial applications, the unique properties of lead still render it irreplaceable.

Zinc

Zinc, a versatile non-ferrous metal, finds itself in numerous industrial applications. Its anti-corrosion properties are widely recognized and make it exceptionally suitable for galvanizing steel and iron products, protecting them from the relentless grasp of rust. This remarkable attribute alone has propelled its extensive use in the construction and automotive sectors, significantly contributing to the longevity of structures and vehicles alike.

Moreover, Zinc plays a vital role in the realm of die casting, a widely employed manufacturing process that enables the production of precisely defined metal parts with smooth or textured surfaces. Its relatively low melting point and exceptional fluidity make it an ideal choice for this application, ensuring the creation of intricate and flawless components.

Beyond its prowess in corrosion protection and casting, Zinc continues to make its mark in the production of batteries, particularly in the zinc-carbon and alkaline varieties. While it may not possess the same durability as certain other metals, zinc’s protective capabilities and energy storage functionality solidify its prominent position in our everyday lives.

With its myriad of industrial uses and unique properties, zinc proves to be an indispensable element that enhances the durability, reliability, and functionality of various products and structures across different sectors.

Silver

Silver, a lustrous white metal with a captivating sheen, stands out among non-ferrous metals due to its exceptional properties. Renowned for its remarkable electrical and thermal conductivity, silver finds extensive use in an array of electrical applications, including the production of conductive pathways in electronic devices, ensuring seamless flow of energy. Beyond its technical prowess, it has been cherished for centuries for its exquisite beauty and timeless charm. Its enduring resistance to corrosion and tarnish renders it a favored choice in crafting exquisite jewelry and ornamental pieces that stand the test of time.

Moreover, silver’s remarkable photosensitive properties have made it an indispensable component in the realm of photography, finding its place in photographic films and the capturing of intricate details in x-rays. In recent years, the remarkable antimicrobial characteristics of silver have been harnessed in the development of innovative healthcare and hygiene products. From advanced wound dressings to antimicrobial fabrics, silver’s versatility in combating harmful microbes has revolutionized the field. Despite its relatively higher cost compared to other metals, the myriad applications of Silver across various industries ensure its sustained demand and enduring significance.

Gold

Gold, a lustrous yellow metal, holds a unique and fascinating role as a non-ferrous metal in both historical and modern contexts. Throughout human history, gold has been highly prized for its rarity, captivating beauty, and exceptional longevity. These remarkable qualities have led to its extensive use in ornamental objects, exquisite jewelry, and as a reliable store of wealth.

In the field of electronics, for instance, gold is utilized to manufacture connectors, switch and relay contacts, soldered joints, connecting wires, and connection strips, owing to its high electrical conductivity and remarkable resistance to oxidation.Notably, Gold’s significance extends to the medical field, where gold alloys find application in fillings, crowns, bridges, and orthodontic appliances. Furthermore, gold isotopes play a vital role as a radiation source in cancer treatment, underscoring its significance in the realm of healthcare.

Beyond its scientific and industrial applications, Gold continues to occupy a central position in the financial sector, serving as a standard for monetary exchange in numerous countries. Despite its relatively high cost, the unparalleled properties and enduring allure of gold ensure its continued relevance and influence across diverse domains.

In summary, Gold’s allure lies not only in its inherent beauty and rarity but also in its remarkable properties that make it indispensable in various fields. From its historical significance to its modern-day applications, gold remains an extraordinary metal that continues to captivate and impact our world in numerous ways.

Titanium

Titanium, a remarkable silver-colored metal renowned for its exceptional strength and low density, possesses an extensive range of applications. Due to its outstanding resistance to corrosion, even in the harsh conditions of salt water, it has become a preferred choice in industries such as marine, aerospace, and chemical processing. Notably, the exceptional strength-to-weight ratio of Titanium renders it an ideal material for components that necessitate enduring stress without burdening excess weight, particularly in the construction of aircraft structures.

Within the medical field, Titanium’s remarkable biocompatibility allows for its utilization in surgical instruments, dental implant devices, and artificial joints. Moreover, owing to its exceptional resistance to extreme temperatures, titanium finds application in the manufacturing of racing and sports car parts.

Despite the relatively higher cost associated with its extraction and processing, the unique properties of Titanium make it an invaluable non-ferrous metal in a wide array of high-performance applications, catering to diverse industries.

Alloys

Alloys are a fascinating and essential part of the non-ferrous metal category. They are meticulously crafted to combine the beneficial properties of multiple metals, resulting in superior performance characteristics. These remarkable materials are created by blending two or more metallic elements into a harmonious mixture. Each alloy exhibits a unique set of characteristics, depending on the elements involved. These properties can be tailored and optimized to meet the specific requirements of various industrial applications.

One notable example of an alloy is Bronze, which is primarily composed of Copper and Tin. Renowned for its hardness and durability, Bronze has been employed since ancient times for crafting weapons, tools, and statues. Another commonly used alloy is Brass, a combination of copper and zinc. Appreciated for its corrosion resistance and excellent acoustic properties, Brass finds its ideal applications in musical instruments and decorative items.

In the realm of precious metals, White Gold emerges as an intriguing alloy. It is crafted by blending gold with elements like Palladium or Nickel, and often Copper or Zinc, resulting in a distinctive silvery color. White Gold serves as an enchanting alternative to pure gold and is primarily used in the creation of exquisite jewelry. Another significant alloy deserving recognition is Stainless Steel. Although technically classified as a ferrous metal due to its iron content, Stainless Steel boasts exceptional corrosion resistance. This remarkable property is achieved by introducing a significant proportion of chromium into the alloy’s composition.

In the realm of high-performance metals, Titanium alloys stand out as extraordinary materials. These alloys can include elements such as aluminum and vanadium, resulting in a combination that exhibits remarkable strength and lightness. Due to these exceptional properties, Titanium alloys are extensively utilized in aerospace and medical applications.

As our technological needs continue to evolve, the science of alloys remains a critical area of exploration. Researchers and scientists constantly push the boundaries of what these combinations of non-ferrous metals can achieve, unlocking new possibilities and applications for these remarkable materials.

What’s The Difference Between Ferrous and Non-Ferrous Metal?

The primary distinction between ferrous and non-ferrous metals lies in their Iron content. Ferrous metals, such as steel and wrought Iron, contain a significant amount of iron, which lends them certain characteristic properties. Due to the presence of Iron, these metals are generally quite strong but are also prone to rust when exposed to moisture, as iron oxidizes in the presence of oxygen and water.

On the other hand, non-ferrous metals do not contain Iron, making them more resistant to corrosion. They are typically more malleable and can be shaped and formed with greater ease compared to ferrous metals. Some examples of non-ferrous metals, as mentioned earlier, include zinc, silver, gold, and titanium. These metals are widely used in various industries, ranging from electronics to healthcare, due to their distinctive properties.

In addition to their individual applications, non-ferrous metals are often combined to create alloys.

This flexibility allows engineers and designers to tailor the properties of the material to meet specific requirements.When considering whether to use ferrous or non-ferrous metals, the choice depends significantly on the requirements of the application in question. Factors such as strength, corrosion resistance, and malleability play a crucial role in determining the most suitable metal for the job. By understanding the differences between ferrous and non-ferrous metals, one can make informed decisions when selecting materials for various applications.[3],[4]

Properties of Non-Ferrous Metals

Resistance to Rust & Corrosion

One of the standout characteristics of non-ferrous metals is their exceptional resistance to rust and corrosion. Unlike ferrous metals, which contain iron and are thus prone to rust when exposed to air and moisture, non-ferrous metals generally do not oxidize or rust in the same manner. This is primarily because non-ferrous metals, such as aluminum, copper, and zinc, lack the iron content that would react with oxygen to form rust.

This remarkable resistance to corrosion makes non-ferrous metals particularly suitable for applications that are exposed to harsh environments and challenging weather conditions. For example, in marine hardware, non-ferrous metals like copper and its alloys, such as brass and bronze, are preferred due to their excellent resistance to seawater corrosion.

Moreover, the corrosion resistance of non-ferrous metals contributes significantly to their longevity and durability. By lowering maintenance costs and extending the lifespan of products and structures made from these metals, non-ferrous metals become an invaluable resource in a wide variety of industries and applications.

The unique property of non-ferrous metals, along with their other beneficial characteristics, underscores their importance and versatility in various industries. Whether it be in construction, transportation, or electronics, non-ferrous metals continue to play a vital role, providing reliable and durable solutions that withstand the test of time and environmental challenges.

Magnetic Properties

Most non-ferrous metals, which lack iron content, are typically not magnetic. This property is highly significant in various applications, particularly in fields like electronics, where magnetic fields could potentially disrupt the functionality of devices. For instance, wiring utilized in the telecommunications sector is commonly crafted from non-magnetic, non-ferrous metals such as Copper or Aluminium.

Nevertheless, it is worth noting that there are exceptions to this general rule. Some alloys, such as Nickel-Aluminium, defy expectations by exhibiting magnetic properties despite being classified as non-ferrous. This intriguing characteristic highlights the remarkable versatility of non-ferrous metals and their alloys across a wide range of applications. Even in cases where specific attributes like magnetism are required, these metals continue to excel.

The overall non-magnetic nature of non-ferrous metals significantly contributes to their value in diverse industries. This unique attribute ensures their reliability and effectiveness in various environments, making them highly sought-after materials.

Weight

Non-ferrous metals, known for their relatively low weight, are highly valued in various industries. Their lightweight nature is particularly advantageous in sectors where weight plays a crucial role, such as aerospace and automotive design. For example, Aluminum exhibits a remarkable combination of lightweight properties and a high strength-to-weight ratio, making it an excellent choice for aircraft construction, car body panels, and other transportation applications that prioritize fuel efficiency. Additionally, Titanium, another non-ferrous metal, possesses greater strength and slightly more weight than aluminum, yet it remains significantly lighter than steel. Consequently, Titanium finds extensive use in military aircraft and space vehicles, where both strength and low weight are essential. Moreover, the lightweight characteristics of non-ferrous metals make them highly desirable in the construction industry, particularly for structures that require both strength and lightness, such as bridges and high-rise buildings. This versatility and ability to meet specific requirements make non-ferrous metals an indispensable choice for numerous industries

Cost

The cost of non-ferrous metals can indeed be a significant factor in their application. Due to their unique properties and the intricate processes involved in their extraction and refinement, non-ferrous metals generally tend to be more expensive compared to their ferrous counterparts. Precious metals like gold, silver, and copper, for instance, are highly sought after and therefore command higher prices in the market.

Moreover, the cost of non-ferrous metals can fluctuate based on various factors such as global supply and demand, geopolitical issues, and advancements in technology. These factors can impact the extraction and processing techniques employed, ultimately affecting the overall cost. However, despite their higher price tag, the exceptional characteristics of non-ferrous metals often justify their use in various applications where their unique properties are essential.

For example, the electronics industry heavily relies on non-ferrous metals such as gold and copper for their excellent electrical conductivity, corrosion resistance, and durability. These metals enable the production of high-quality electronic components that can efficiently transmit and store electrical signals. Similarly, the aerospace industry depends on lightweight metals like aluminum and titanium, despite their relatively higher cost, to meet stringent weight requirements while ensuring strength and durability. These metals play a crucial role in the construction of aircraft and spacecraft, contributing to enhanced fuel efficiency and overall performance.

Considering the complex dynamics of non-ferrous metal costs, it is essential for industries and businesses to carefully evaluate their unique requirements and cost-benefit analysis when choosing between ferrous and non-ferrous materials. While non-ferrous metals may come at a higher price, their exceptional properties and performance advantages make them indispensable in numerous critical applications.

Recycling

Non-ferrous metals, such as Aluminum, Copper, and Lead, are highly recyclable, adding tremendous value and contributing to sustainability efforts. What sets these metals apart is their remarkable ability to be recycled an infinite number of times without compromising their essential properties. This exceptional quality makes them exceptionally environmentally friendly, as recycling non-ferrous metals consumes far less energy and resources compared to the extraction and refinement of new metals.

These versatile metals can be found in a wide range of everyday products and infrastructure, making them easily accessible for recycling. When these metals reach the end of their useful life, they can be collected, processed, and reintroduced into the manufacturing cycle. This not only reduces the demand for virgin metals but also significantly decreases the amount of waste sent to landfills, minimizing the environmental burden.

It is worth noting that the recycling of non-ferrous metals plays a pivotal role in the global economy. It not only creates job opportunities and generates revenue but also contributes to energy conservation. For instance, recycling aluminum alone can save up to an impressive 95% of the energy required to produce the metal from raw materials. These incredible statistics highlight the immense benefits of non-ferrous metal recycling.

Despite these remarkable advantages, the full potential of recycling non-ferrous metals has yet to be fully realized. Increasing the recycling rates of these metals is a crucial strategy for promoting sustainable development and mitigating the environmental impacts associated with metal extraction and usage.

FAQ

What Is Ferrous Vs Non-Ferrous?

Ferrous and non-ferrous metals are classifications that denote the presence or absence of Iron in their composition. Ferrous metals, as the name implies, contain Iron. They are known for their exceptional strength and durability, making them an ideal choice for applications that require robust materials. However, due to their iron content, ferrous metals are prone to rusting, which can impact their longevity if not properly protected. Common examples of ferrous metals include carbon steel, alloy steel, cast Iron, and wrought Iron. These metals are widely used in industries such as construction and automotive due to their high tensile strength and ability to withstand heavy loads.

On the other hand, non-ferrous metals do not contain Iron in their composition. They are noted for their wide range of properties, including light weight, higher resistance to rust and corrosion, and excellent electrical and thermal conductivity. Non-ferrous metals, such as copper, aluminum, lead, zinc, nickel, titanium, and precious metals like gold and silver, offer versatility in various applications. These metals find extensive use in industries including electronics, aerospace, telecommunications, and more.

The choice between ferrous and non-ferrous metals often depends on the specific requirements of the application in question. While ferrous metals offer exceptional strength and durability, non-ferrous metals provide added benefits such as versatility in weight, corrosion resistance, and conductivity. Understanding the properties and characteristics of these two different types of metals is crucial when selecting the appropriate material for a given application. Taking into account factors such as load-bearing capacity, environmental conditions, and desired functionality is key to making an informed decision.

Why Are Metals Non-Ferrous?

The classification of metals as non-ferrous is primarily based on their lack of Iron content. Iron, being a ferrous element, is commonly found in many metals and imparts specific properties like magnetism and high tensile strength. However, it also renders them susceptible to rust and corrosion. On the other hand, non-ferrous metals are completely devoid of iron. This absence of iron gives rise to a range of unique properties in non-ferrous metals, including resistance to rust and corrosion, lighter weight, and enhanced electrical and thermal conductivity. These exceptional characteristics make non-ferrous metals highly suitable for a wide array of applications across various industries, such as aerospace, automobile, electronics, and telecommunications.

Additionally, the extraction processes for non-ferrous metals are often more complex compared to ferrous metals. This complexity contributes to their higher cost. However, the benefits they offer, such as superior performance and longevity, often justify their use even at a higher price point. By opting for non-ferrous metals, industries can ensure the durability, efficiency, and reliability of their products, making them a preferred choice in many applications.

What Are 5 Types Of Non Ferrous Metals?

- Aluminum: Lightweight and highly malleable, aluminum is used in a vast range of applications, from beverage cans to aircraft structures. It is renowned for its excellent corrosion resistance and high thermal and electrical conductivity.

- Copper: Known for its exceptional electrical conductivity, copper is typically employed in the manufacturing of electrical wires. It’s also used in plumbing, roofing, and in the production of various alloys like bronze and brass.

- Lead: Highly dense and soft, lead is used in a variety of applications, including batteries, radiation shields, and weights. It is also used in the production of solder and pewter.

- Zinc: Primarily used as a protective coating for iron and steel (galvanization), zinc also finds use in the production of alloys like brass and bronze, and in batteries.

- Titanium: Noted for its strength-to-weight ratio and corrosion resistance, titanium is often used in aerospace applications, medical devices, and jewelry. Its resistance to seawater corrosion also makes it ideal for use in marine applications.

Is Gold A Non-Ferrous Metal?

Yes, Gold, a precious metal, is classified as a non-ferrous metal due to its absence of Iron. Renowned for its captivating luster, gold exhibits exceptional properties such as malleability, ductility, and resistance to corrosion.

This noble metal’s outstanding electrical conductivity makes it highly sought after in the electronics industry, where it is extensively used. Additionally, Gold finds application in the production of exquisite jewelry, coinage, and even in dentistry and medicine. Its remarkable ability to reflect electromagnetic radiation contributes to its usage in aeronautical applications. Despite its relatively high cost, the unique and invaluable characteristics of Gold render it indispensable across a multitude of industries.

What Are 3 Differences Between Ferrous And Non Ferrous Metals?

One of the most definitive differences between ferrous and non-ferrous metals lies in the presence of Iron. Ferrous metals, containing it, exhibit exceptional strength and durability, making them suitable for various applications. On the other hand, non-ferrous metals lack iron, which imparts properties such as lightweightness and corrosion resistance.

Speaking of corrosion resistance, this is another crucial distinction between the two types of metals. Due to their iron content, ferrous metals are prone to rust when exposed to moisture or oxygen. In contrast, non-ferrous metals exhibit remarkable resistance to rust and corrosion, making them highly suitable for applications in harsh weather conditions or corrosive environments.

Moreover, when it comes to weight and density, ferrous metals tend to be heavier and denser. This characteristic makes them an ideal choice for applications that require high strength, such as construction and automotive industries. Conversely, non-ferrous metals are generally lighter, making them perfect for industries like aerospace and electronics, where weight plays a critical role.

In summary, the presence of Iron, corrosion resistance, and weight characteristics are key factors that differentiate ferrous and non-ferrous metals, offering unique advantages for various industries and applications.

How Do You Identify Non-Ferrous Metals?

Identifying non-ferrous metals involves several methods, each with its own unique characteristics and indications. The most commonly used methods include visual inspection, magnet test, and spark test.

During visual inspection, non-ferrous metals like copper, brass, and aluminum can be easily recognized by their distinctive colors. For example, copper exhibits a reddish-brown hue, while aluminum has a dull silver color. This visual distinction aids in quickly identifying these metals.

The magnet test is another effective method. Since non-ferrous metals are not magnetic, a simple test involves checking if a magnet sticks to the metal. If the magnet does not stick, it is likely a non-ferrous metal. This straightforward technique helps differentiate non-ferrous metals from their ferrous counterparts.

Additionally, the spark test can provide valuable insights. By subjecting the metal to a grinder, different metals produce sparks with varying characteristics. Ferrous metals produce long, white sparks, whereas non-ferrous metals like copper and aluminum do not produce sparks. However, it is important to exercise caution when conducting this test due to safety considerations.

It is crucial to note that these methods serve as general guidelines, and there may be exceptions. In certain scenarios, more advanced techniques such as chemical analysis or spectroscopy might be necessary for accurate identification. If you are uncertain, it is always recommended to consult a professional for expert advice and assistance in identifying non-ferrous metals.

Useful Video: Ferrous & Non-Ferrous Metals | Piping Analysis

Conclusion

Non-ferrous metals, which are metals that do not contain iron, possess a remarkable set of properties that set them apart. These properties include exceptional resistance to corrosion, lightweight composition, and outstanding electrical and thermal conductivity. These unique characteristics make non-ferrous metals highly desirable for a wide range of applications across multiple industries, including aerospace, automobile manufacturing, electronics, and telecommunications.

While the extraction processes for non-ferrous metals can be intricate and costly, the benefits they offer are truly invaluable. Identifying these metals can be achieved through various methods, ranging from simple visual inspection to more advanced techniques like chemical analysis. As the use of non-ferrous metals continues to evolve and expand, understanding their properties and applications remains crucial in driving technological progress and fostering innovation.

By harnessing the potential of non-ferrous metals, we can unlock new possibilities and pave the way for groundbreaking advancements in various fields. Whether it’s improving the efficiency of electronic devices or enhancing the performance of aerospace components, the versatility and reliability of non-ferrous metals play a vital role in shaping the future of technology.

References:

- https://www.twi-global.com/technical-knowledge/faqs/what-metals-are-non-ferrous

- https://www.cabww.com/casting-and-forgings/non-ferrous-castings

- https://www.twi-global.com/technical-knowledge/faqs/ferrous-vs-non-ferrous-metals

- https://www.slrecyclingltd.co.uk/what-is-the-difference-between-ferrous-non-ferrous-metals/