How Much Does a Metal 3D Printer Cost?

3D printing technology has come a long way in recent years, and one of the most exciting developments is the ability to print metal objects. Metal 3D printers are now available for both commercial and personal use, but what do they actually cost? In this blog post, we’ll take a look at the different factors that affect the price of a metal 3D printer so you can make an informed decision about whether or not this technology is right for you.

What Is a 3D Printer?

Transform your digital designs into tangible, three-dimensional objects with a 3D printer. To begin 3D printing, one must first create a design using computer-aided design (CAD) software and then convert it into an appropriate format for the printer’s understanding.

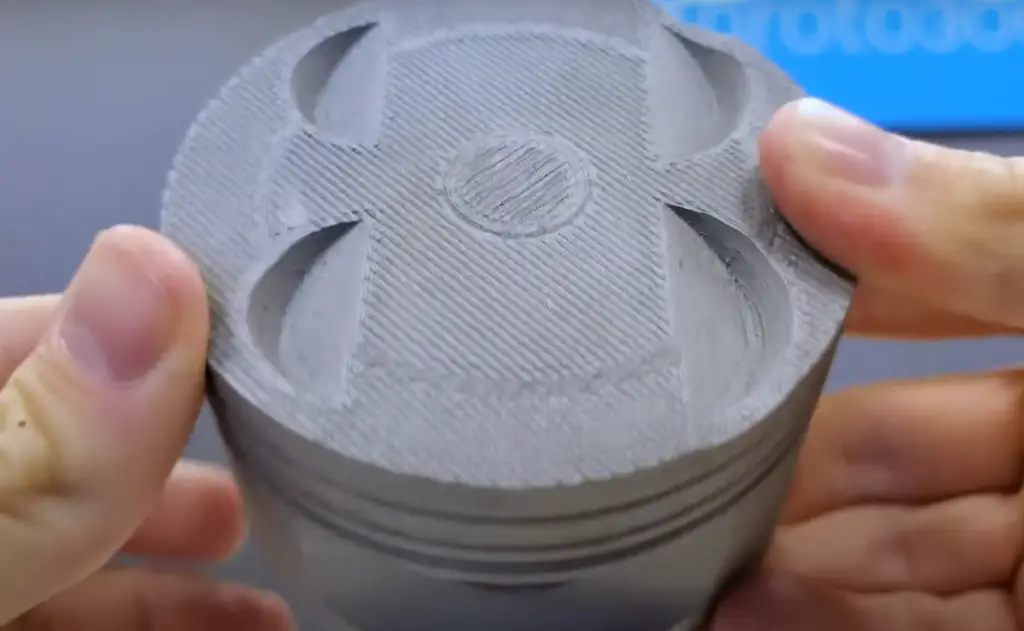

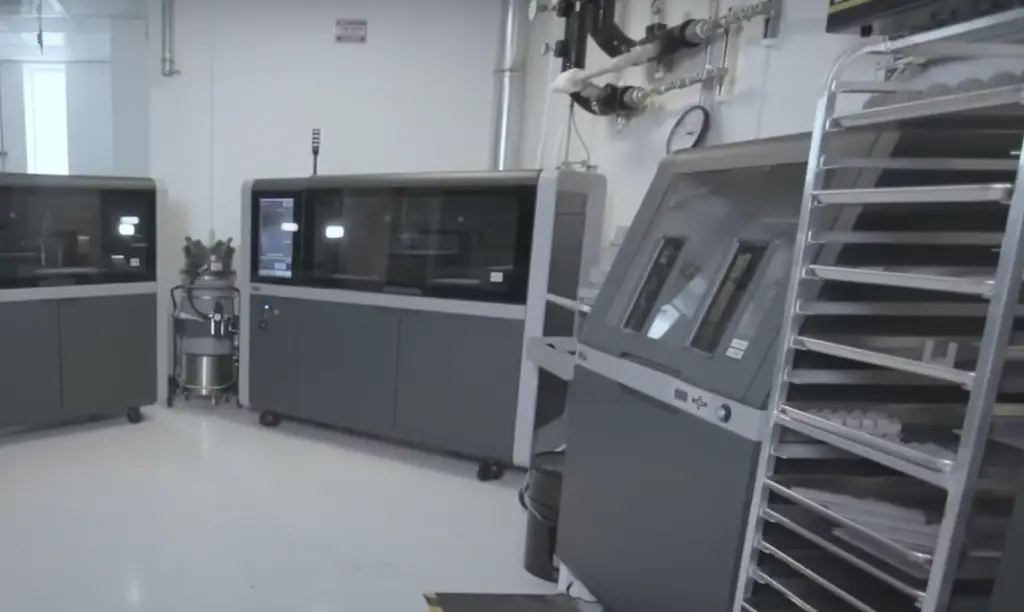

The resulting object is printed layer by layer from plastic, metal, or other materials depending on the type of 3D printer being used. Metal 3D printers are becoming increasingly popular for industrial applications due to their ability to quickly and accurately create complex parts with high levels of detail and accuracy. [1]

How Much Does a Metal 3D Printer Cost?

If you’re looking to add a metal 3D printer to your business or home workshop, you’re probably wondering how much it will cost. The truth is, the price of a metal 3D printer can vary widely depending on the features and capabilities you need.

At the low end, you can find metal 3D printers that start around $5,000. These entry-level models are typically smaller in size and have fewer features than more expensive models. However, they can still be used to create high-quality metal parts and objects.

At the other end of the spectrum, there are industrial-grade metal 3D printers that can cost tens of thousands of dollars. These machines are larger and more powerful, with the ability to create complex metal parts and objects.

In general, you can expect to pay between $5,000 and $50,000 for a metal 3D printer. The exact price will depend on the features and capabilities you need.

Cost Drivers

Material

Material cost is one of the biggest drivers when it comes to metal 3D printing pricing. It depends on the type of metal being used and the size of the build. Generally, metals like titanium and stainless steel are more expensive than aluminum and cobalt-chrome alloys. Additionally, larger prints may require more material use, resulting in higher costs overall.

Design Software

3D printing requires complex software to design the components. Specialized CAD (computer-aided design) programs are necessary for designing the intricate parts that are suitable for 3D printing.

Additionally, certain 3D printer manufacturers may use proprietary software, which can drive up the cost of a metal 3D printing project if you don’t already have access to it.

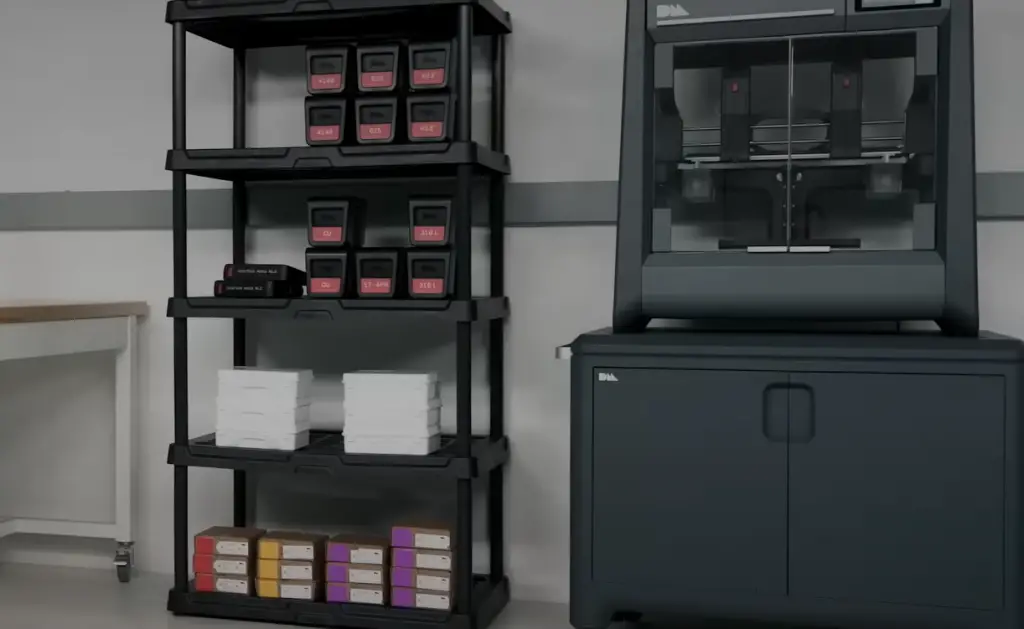

Set Up Costs

Many metal 3D printers require additional set-up costs outside of the machine itself. These include maintenance fees and additional hardware or supplies needed to get started. Some manufacturers also charge extra for training on how to use their specific machine, adding yet another expense factor when considering a metal 3D printing project. [2]

Labor

Another major cost driver is labor.

This can add up quickly with additional costs for labor and materials. Additionally, some metal 3D printers are so specialized that they require a highly trained operator, which may cost more than an ordinary print job.Features

Finally, the features and capabilities of metal 3D printers vary greatly. High-end models may offer additional functionality such as faster printing speeds, higher resolution, and more advanced features. This can also lead to a higher cost if you’re looking for these types of machines.

Post-Processing Cost

After a metal 3D printing job is complete, post-processing may be necessary. This includes additional steps such as sandblasting or heat treating. These processes can lead to additional cost drivers that need to be considered prior to starting the project.

Ultimately, the cost of a metal 3D printer depends on many factors, including material choice, design software costs, set up fees, labor expenses, and features desired.

Understanding all of these elements will help you determine the best machine for your project needs and budget.

By doing some research ahead of time and weighing all your options carefully, you can be sure to get the most value out of your metal 3D printing investment!

Which Metal 3D Printer Do I Need?

The type of metal 3D printer you need will depend on the scope and complexity of your project. If you’re just getting started, it might be wise to invest in a more affordable desktop machine, while larger projects may require an industrial-grade printer with greater capabilities. That said, whatever your budget and intended application, there are many options available that can meet your needs.

When shopping for a metal 3D printer, there are several key factors to consider: build volume (the maximum size of the objects you can print), material compatibility (what types of metals the printer can use), accuracy (how precise the prints are) and speed (how quickly objects can be printed). You should also think about features like automatic shutdown and heated platforms, which can save time and money.

As with any major investment, it’s important to do your research and find the printer that best fits your needs. You should also compare prices from different manufacturers and see what kind of support they provide – such as warranties or customer service – to ensure you get the most value for your money. With the right machine and a bit of practice, you can start turning out high-quality 3D printed metal parts in no time! [3]

Things to Consider Before 3D Printing Metal

When it comes to 3D printing metal, there are a few things you should keep in mind before making your purchase. The first thing to consider is the cost of the printer itself. Metal 3D printers can range in price from a few hundred dollars to several thousand dollars.

The next thing to consider is the cost of the metal filament or powder that you will need to use with the printer. Metal filaments and powders can be quite expensive, so you will need to factor that into your budget as well.

Finally, you will need to consider the cost of any post-processing that you might need to do on your prints. Some metals can be difficult to work with and may require special finishing techniques in order to get a smooth, polished finish. This can add to the overall cost of your project.

With all of these factors in mind, you should be able to get a ballpark estimate of how much it will cost to 3D print metal. The actual cost will vary depending on the specific printer and materials that you choose. However, by considering all of the factors mentioned above, you should be able to get a good idea of the total cost involved. [4]

Metal 3D Printing Services

Metal Powder Bed Fusion 3D Printing

Metal 3D printing services offer businesses the chance to access Metal Powder Bed Fusion (MPBF) 3D printing technology without investing in their own printer.

With these services, companies can manufacture parts on-demand and reduce lead times while also avoiding large upfront investments in equipment.

Directed Energy Deposition (DED) 3D Printing

Directed Energy Deposition (DED) 3D printing services are also available, allowing businesses to take advantage of the technology without investing in their own printer. DED 3D printers use a high-powered laser or electron beam to fuse powdered metal into the desired shape and size. Businesses can use these services to quickly create parts with intricate details for a variety of applications.

Binder Jetting 3D Printing Services

Binder 3D Printing.DED 3D printing services offer businesses the chance to access Directed Energy Deposition (DED) 3D printing technology without investing in their own printer.

Metal Filament Extrusion 3D Printing

Metal filament extrusion 3D printing services are also available, allowing businesses to access the technology without making a large upfront investment. In this process, metal powder is mixed with plastic to create a filament that can be used for 3D printing. Metal filaments are ideal for creating complex parts in a variety of materials and alloys.

Pros and Cons of a 3D Metal Printer

Pros of a 3D Metal Printer

- Durability: Metal is typically much stronger than plastic and can be used to create large, durable parts and objects.

- Quality: The quality of metal-printed materials can be quite high, with the ability to print intricate shapes and thin walls.

- Versatility: With the right kind of metal alloy, almost any shape or size imaginable can be printed in 3D.

Cons of a 3D Metal Printer

- Expense: A metal 3D printer is significantly more expensive than a plastic 3D printer. The cost of the equipment, as well as materials such as filament, metals powders, and other specialized supplies, can add up quickly.

- Complexity: Metal 3D printers are generally more complex to operate than their plastic counterparts. The process of sintering metal powder can be complicated and time-consuming, and often requires specialized knowledge and training.

- Health and Safety Risks:Metal 3D printing can release harmful particles into the air, which can pose serious health risks if inhaled. It is important to take precautions when operating a metal 3D printer, such as wearing a respirator or working in a well-ventilated area.

In conclusion, a metal 3D printer can be an expensive yet worthwhile investment for those looking to create high-quality, durable objects. However, it’s important to consider the potential risks and costs associated with operating such a device before taking the plunge. With proper safety protocols in place, and knowledge of how to use the machine properly, a metal 3D printer can prove to be a valuable asset for any business or individual. [5]

Which Metals Can You 3D Print?

Metal 3D printing is revolutionizing the way things are made. From medical implants to aerospace components, engineers and manufacturers are using metal 3D printers to create parts quickly and cost-effectively, opening up new possibilities for complex geometries and designs that were not previously possible. But which metals can you 3D print?

The answer depends on the type of metal 3D printer being used. The most common types of metal 3D printers are Direct Metal Laser Sintering (DMLS) machines, Electron Beam Melting (EBM) machines and Selective Laser Melting (SLM). These technologies use lasers or electron beams to melt metallic powders into a desired shape layer by layer. Each technology has its own set of advantages and disadvantages, but they generally work with similar metals.

Aluminum, stainless steel, cobalt chrome, and titanium are the most common metals used in 3D printing.

Stainless steel is stronger than aluminum and resistant to corrosion, making it a popular choice for industrial applications. Cobalt chrome is harder than other metals and can withstand high temperatures and harsh environments, making it the perfect choice for medical implants or aerospace components. Titanium is strong yet lightweight, allowing engineers to design complex parts that weigh less but still have excellent strength properties.Metal 3D printing offers manufacturers many benefits such as shorter lead times, improved efficiency and cost savings. As the technology continues to evolve, more metals will become available for 3D printing — opening up an exciting new world of possibilities!

Applications For Metal AM Systems

Metal AM systems are used for a variety of applications in various industries. Many companies have implemented metal 3D printers to create complex parts and components for products, including aerospace, automotive, medical, and consumer goods.

The aerospace industry is one of the largest adopters of metal AM technology due to the complexity of certain aircraft engine components. These components often involve intricate internal structures that can be manufactured quickly with metal 3D printing processes like direct energy deposition (DED). Metal 3D printed parts are also used in aircraft frames and fuel systems.

The automotive industry uses metal 3D printing primarily for prototyping and tooling applications because of its speed, accuracy, and cost efficiency compared to traditional manufacturing techniques. This technology enables companies to reduce the time and cost associated with creating prototypes, as well as manufacture components for production-ready cars.

The medical industry is also using metal 3D printing for a range of applications, including orthopedic implants, dental devices, and prosthetics. Metal 3D printing can produce complex parts quickly and accurately with minimal waste. Additionally, many medical device manufacturers are utilizing AM technology to create customized products that meet patient-specific needs.

Finally, consumer goods companies have adopted metal 3D printing to quickly create intricate parts that would be difficult or impossible to make with traditional techniques.

In conclusion, metal 3D printing technology is being utilized in a wide range of industries to create complex parts and components quickly and cost-effectively. Companies are able to realize significant time and cost savings by implementing metal AM systems into their production processes. Ultimately, this technology helps companies develop new products faster and more efficiently than ever before. [6]

FAQ

How much does it cost to 3D metal print?

The price of metal 3D printing can vary depending on the printer you use, as well as the metal you’re printing with. In terms of printers, industrial-grade machines can cost anywhere from $100,000 to over $1 million. However, there are also lower-cost options available for around $10,000. As for metals, the price will depend on the type and quantity you need. In general, aluminum is the cheapest metal to print with, while titanium is the most expensive.

What are some common uses for metal 3D printing?

Metal 3D printing is often used for prototyping and small-scale production runs. It’s also commonly used to create customized parts or ones that would be too difficult or expensive to produce using traditional methods. Common applications include medical implants, aerospace parts, and automotive components. Additionally, 3D metal printing can be used for intricate art pieces and jewelry.

What is the process of metal 3D printing?

The basic process of metal 3D printing involves melting a metal powder with an electron beam or laser in order to build up a part layer by layer. This process is known as Direct Metal Laser Sintering (DMLS). After each subsequent layer has been printed, the object is then sintered together into a single solid form. Depending on the size of your project, this process can take anywhere from several hours to several days.

Are there any safety concerns when using a metal 3D printer?

Since metal 3D printers use high-powered lasers, there is always a risk of fire. It’s important to have a fire extinguisher on hand when using one of these machines. Additionally, you should wear protective gear, such as gloves and goggles, to avoid coming into contact with the laser beam or hot metal powder.

Is 3D printing metal cost effective?

The cost of metal 3D printing can vary greatly depending on the materials used and the complexity of the design. Generally, metal 3D printing is most cost effective when relatively simple parts are needed in high volumes. For complex designs or low volume production, traditional fabrication methods may be more cost effective. In terms of raw materials, metals such as steel and aluminum are among the least expensive materials that can be used for 3D printing. In addition, many industrial-grade metal powders are now available which offer a significant cost savings over using virgin metals.

The other major factor influencing the cost effectiveness of 3D printing with metal is speed. Metal 3D printers operate much slower than those designed for plastic filaments and the cost of printing is generally tied to print time. As such, metal 3D printers are best suited for applications which involve relatively low-volume production or prototyping. In summary, while the cost of 3D printing with metal can be significant, it is often a worthwhile investment in certain cases where speed and complexity are important factors. By selecting the appropriate materials and understanding the limitations of metal 3D printing, businesses can make informed decisions about their projects and ensure they find the most cost effective solution for their needs.

Can you get a metal 3D printer?

Yes, metal 3D printers are widely available for purchase. They can be found in a variety of shapes and sizes, with prices ranging from several thousand dollars to tens of thousands depending on the capabilities and size of the machine. In addition to dedicated metal 3D printing machines, some plastic 3D printers can also be modified to work with metal filaments or powders.

What metals can not be 3D printed?

Most metals can be 3D printed, but there are some limitations. Generally speaking, softer metals such as gold and silver are not suitable for 3D printing due to the difficulty in controlling their properties during the printing process. Metals which require high temperatures for melting or processing are also difficult to use with 3D printers, as many machines cannot reach these temperatures. Additionally, certain alloys may be difficult to print depending on their composition and the type of 3D printer being used. It is important to review the capabilities of a given machine before attempting to print with any metal material.

Is metal 3D printing toxic?

Metal 3D printing can be a safe and non-toxic endeavor, provided that proper safety protocols are followed. In terms of health risks, the primary concern is exposure to airborne particles from metal powders or fumes produced during the printing process. To mitigate these risks, operators should wear protective clothing and use appropriate ventilation when working with metal 3D printers. Additionally, it is important to regularly clean and maintain the machine in order to reduce any potential hazards.

What are the disadvantages of 3D metal printing?

3D metal printing has several significant disadvantages. Firstly, the process is much slower than traditional methods of fabrication and as such, it is not suitable for large-scale production runs. Additionally, due to the complexity of working with metals, 3D printers are limited in terms of size and shape which can be printed. Finally, 3D printing with metals typically requires a greater degree of expertise and experience compared to plastic 3D printing.

Useful Video:How Much Does Metal 3D Printing cost? Here are Some Examples.

Conclusion

The cost of a metal 3D printer can vary dramatically depending on the size, capabilities and features it offers. Smaller desktop models may start at around $5,000 whilst larger industrial models can cost upwards of $100,000. The cost is an investment that should be weighed against the benefits that such a machine can offer in terms of time savings and production costs. As technology develops and more affordable solutions become available, so too does the potential for increased accessibility to this type of printing technology for businesses and individuals alike. Ultimately, it can be concluded that metal 3D printing is an evolving technology that has the potential to revolutionize the way products are created and manufactured. To take full advantage of its capabilities, businesses need to consider their needs and budget carefully when selecting a machine that best suits their individual requirements.

References:

- https://all3dp.com/2/how-much-does-a-metal-3d-printer-cost/

- https://www.aniwaa.com/buyers-guide/3d-printers/best-metal-3d-printer/

- https://jiga.io/resource-center/3d-printing/metal-3d-printer-cost-expensive/

- https://www.3dnatives.com/en/iro3d-lowers-cost-3d-metal-printing-machine-271120185/

- https://layers.app/blog/how-much-does-it-cost-to-3d-print-metal-parts/

- https://www.xometry.com/resources/3d-printing/metal-3d-printer-cost/