Does Metal Expand When Heated?

When metal is heated, its molecules begin to vibrate and move faster. This causes the metal to expand. However, how much expansion occurs depends on the type of metal and how hot it gets. In this blog post, we’ll investigate the intricate details of how different metals react to heat and what causes them to expand. So if you’ve ever wondered whether your favorite metal bracelet or ring will get bigger when you wear it in the summer sun, read on!

The Effect of Heat on Different Metals

When heated, different metals will expand at varying rates. Generally, metals with a higher rate of thermal expansion are more susceptible to changes in temperature and have an increased chance of warping or bending when exposed to heat. In comparison to metals, such as aluminum and copper, which expand significantly when exposed to heat, stainless steel and titanium have substantially lower thermal expansion coefficients. The amount that metal will expand can also be affected by the thickness of the metal as thicker pieces will generally contract less than thinner pieces when heated up.

It is essential to consider this when selecting metals for projects such as piping systems or constructing structures, since some varieties may be unsuitable due to their propensity for rapidly expanding in specific temperatures. For example, for pipes carrying hot water, stainless steel or titanium may be a better choice than aluminum as the latter will expand much more when heated.

In conclusion, it is clear that different metals react differently to heat and have varying levels of thermal expansion coefficients. This should be taken into account when selecting materials for projects such as piping systems or building structures where metal is used in order to ensure that the chosen material can withstand the temperatures it will be exposed to without warping or bending excessively. Knowing which metal is best suited for a particular application can help prevent any unexpected issues later on down the line. [1]

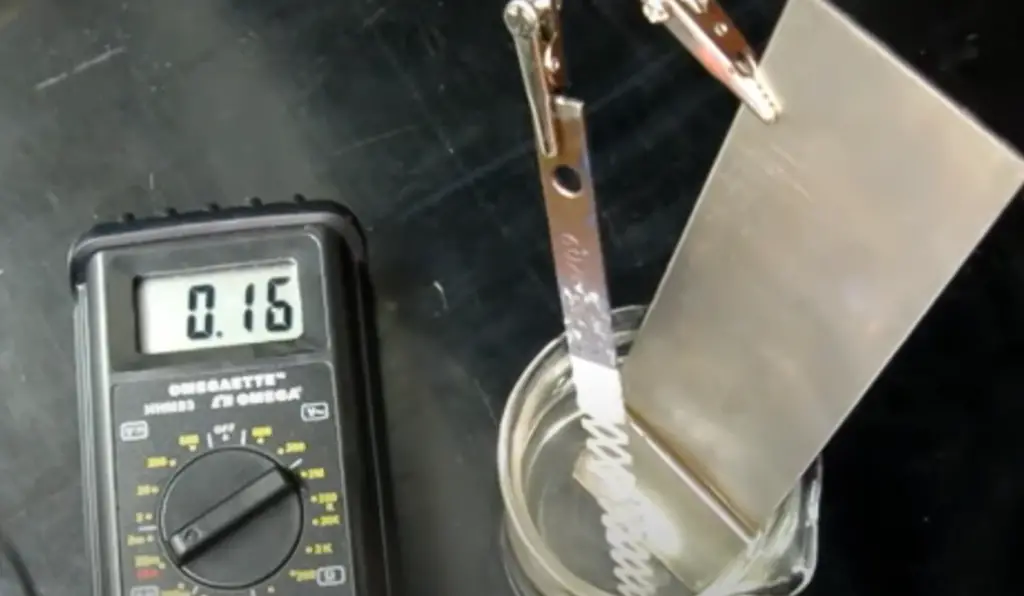

Electrical Resistance

Metal expands slightly when heated, but its electrical resistance also increases. This is because the increased temperature causes electrons to move more quickly through the metal, creating a higher electric current in the material. As a result, the electric field within the metal becomes stronger and the energy required to push an electron through it is greater.

The increase in electric resistance creates heat that warms up surrounding areas of the metal, causing further expansion. Ultimately, this means that heating up metal will cause not only physical expansion of the material itself but also increased electrical resistance.

Thermal Expansion

Thermal expansion is the increase in size and volume of a material due to increased temperature. This phenomenon affects all materials, including metal, but different metals have different coefficients of thermal expansion (CTE). Generally speaking, metals with high CTE values will expand more than those with low CTE values when exposed to elevated temperatures.

For example, steel has a relatively high coefficient of thermal expansion compared to other metals such as aluminum or copper. As such, heated steel will expand at a faster rate than these other materials when subjected to the same amount of heat.

The degree of thermal expansion also depends on how quickly a material is heated up; if it is done too quickly, the metal may expand in an uneven manner and could potentially cause strain and damage to the structure of the material. Therefore, it is important to be mindful of the rate at which a metal is heated when using it in manufacturing or engineering purposes. [3]

Structure

When heated, most metals expand, but the rate of expansion varies depending on the metal. For example, steel expands more than copper when exposed to heat.

This measurement helps engineers calculate how materials will react over time and in different conditions.The way a metal responds when heated depends on its structure and atomic makeup. Metals with high melting points tend to have tight-knit structures that resist expanding too quickly due to their strong intermolecular forces; softer metals like aluminum or lead may expand more easily due to their looser atomic structure. Furthermore, the rate of expansion may be affected by environmental factors such as air pressure or humidity.

Magnetism

When heated, metal expands as its particles vibrate more rapidly and move further apart. This expansion occurs in all metals except ferromagnetic metals such as iron and steel that are strongly attracted to magnets. These types of metals do not expand when heated due to their magnetic properties; instead, the temperature of the metal causes it to become less magnetized. As a result, ferromagnetic metals do not experience an increase in size with increasing temperatures. When these materials are cooled, however, they return to their original magnetic state and contract back to their original size.

Heat Treatment

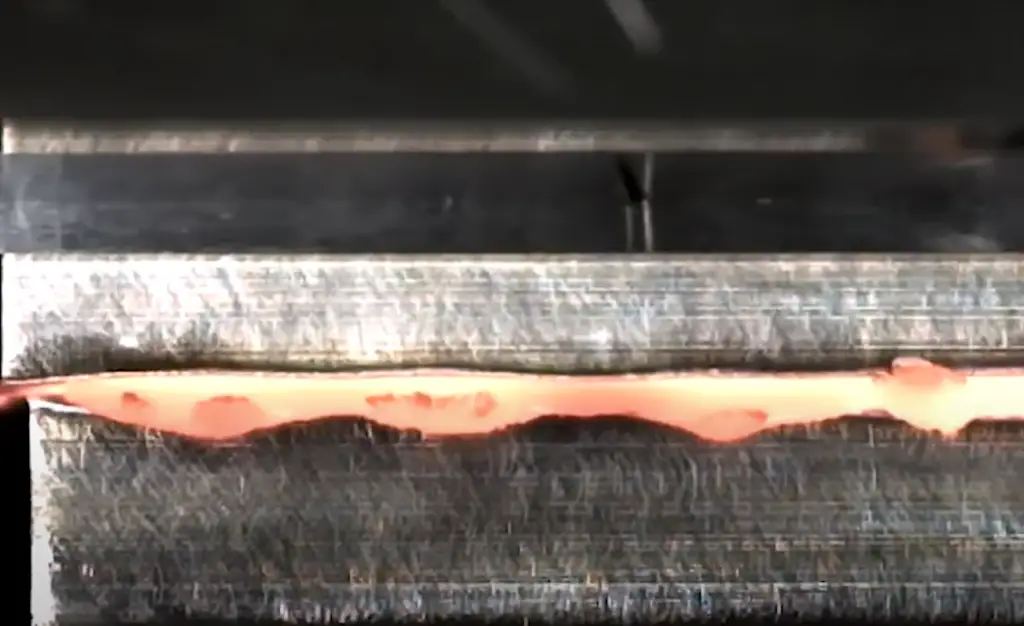

Heat treatment of metals is a common practice in industries, including the automotive and aerospace sectors. Heat treatment of metals involves heating and cooling them to change their physical and mechanical properties. It can improve ductility, strength, hardness, wear resistance, corrosion resistance and other characteristics.

Annealing

Annealing is a process by which metal is heated, then slowly cooled to improve its toughness and ductility. The heat causes the molecules of the metal to move more freely, allowing them to expand and contract as necessary. This can help relieve internal stress and make the metal easier to work with. However, it should be noted that while annealing can cause some expansion, it won’t impact the overall size of the metal significantly – so if you need something larger or smaller than what you started with, you’ll need to look elsewhere!

Additionally, annealing isn’t appropriate for all kinds of metals – usually only ferrous and non-ferrous metals respond favorably. So if you’re looking for a way to increase the size of your metal, it’s best to do some research beforehand to make sure annealing is the right solution. [4]

Normalizing

It is another process used to modify the properties of metals. This involves heating a metal to a high temperature and then cooling it in still air. It increases the grain size and uniformity, resulting in greater strength and toughness.

Hardening

Heating and cooling causes changes to the structure of metals. When heated, metal expands, becoming softer and easier to shape. However, some metals can be hardened through a process called quenching. This involves rapidly cooling the metal in cold water or oil after it has been heated. This makes the metal harder and more resistant to wear and tear than before. Quenched metals are much less likely to deform or break under strain than unquenched ones.

By carefully controlling the heating and cooling process, gauges can be created that are strong enough for industrial use yet still have considerable ductility. Hardening is an important technique used in many industries including automotive, construction, aerospace and marine engineering sectors where strength is a priority. Hardened steel is also used to make tools, knives and other items that require a tough and durable material.

Tempering

Sometimes, a metal needs to be strengthened without becoming too hard. Tempering is the process of reheating and cooling a material to create specific characteristics in its structure. This can increase the strength of the metal while also making it more ductile and less brittle than before. This is achieved by heating the metal up to a certain temperature, then slowly cooling it down until it reaches room temperature. The size of the grains within the metal will depend on how quickly or slowly it’s cooled; slower cool-down gives larger grain sizes which help make the metal stronger but also more brittle.

Conversely, fast cooling creates smaller grains that are both tougher and more flexible than their larger counterparts. Carefully controlling this process allows engineers and manufacturers to produce metals with just the right balance of strength and flexibility. Tempered metal is used in products such as automotive parts, tools, kitchen utensils, aircraft components and building materials. [5]

How To Minimize The Effects Of Heat On The Measurement Of Metal Parts?

When working with metal parts, it is important to be aware of how heat and temperature can affect the accuracy of measurements. Metal expands when heated, so if a part is measured in an environment that is too warm or at temperatures that exceed the melting point for the material in question, then this will affect the measurement results. Here are some tips to keep in mind to minimize the effects of heat on your measurements:

- Use thermal compensation methods such as using infrared thermometers to measure surface temperature before making any measurements. This ensures that any expansion caused by heat has been accounted for prior to measuring.

- If possible, take measurements in an environment that has been cooled down slightly below room temperature as this will reduce the amount of thermal expansion that can occur.

- If measuring a part that is already hot, allow it time to cool off prior to taking measurements as this will ensure any expansion due to heat has been taken into account.

- Use special insulation techniques such as wrapping the part in plastic or foam and storing in a cooled environment for a period of time before taking measurements. This will reduce the amount of thermal energy absorbed by the material and help minimize thermal expansion.

By following these tips, you can be sure that your metal parts are measured accurately regardless of temperature changes or other external factors. Taking proper precautions when measuring metal parts ensures accuracy, saves time and money, and eliminates the risk of unintended consequences due to mis-measurement.

Factors In The Heat Expansion Of Metals

When metals are heated, they tend to expand. This phenomenon is known as thermal expansion and occurs because the molecules of the metal gain kinetic energy from being exposed to heat and begin to move freely. To understand how thermal expansion works, it is important to consider certain factors that can affect its magnitude.

The first factor is the type of metal being heated. Different types of metals respond differently when exposed to heat due to their different structures, compositions, and atomic masses. Metals with higher densities often have lower coefficients of thermal expansion, meaning they will expand less than lighter metals when exposed to comparable amounts of heat.

Another factor is the temperature at which the metal is heated. Generally speaking, heat causes greater expansions in metals at higher temperatures. If the temperature of a metal is increased from its initial temperature, it will expand in proportion to the change in temperature. Furthermore, certain metals can reach a point where further increases in temperature result in no further expansion.

Finally, the rate at which heat is applied to the metal can also influence its thermal expansion. Metals often experience less expansion when heated slowly than when heated rapidly due to differences in how the molecules of each metal absorb and release heat energy over time. [6]

FAQ

Does metal expand in cold?

No, metal typically contracts when cooled. This is because the atoms become denser and closer together as they lose energy with decreasing temperature. The contraction of metals when cooled is known as thermal expansion. However, some metals like Bismuth can expand slightly when cooled.

Does metal expand in heat?

Yes, most metals will expand when heated due to thermal expansion. As the atoms gain energy from increasing temperatures, they vibrate faster and move away from each other, resulting in an increase in volume and length of the material. The amount of thermal expansion varies depending on the type of metal being heated.

How much will a metal expand from heat?

The amount of expansion will depend on the material, temperature, and other factors. Generally speaking, most metals expand when heated. As a metal is heated, its particles begin to vibrate and move farther apart from each other, increasing the overall volume of the metal. The amount of this expansion can range from very small (a few millionths of an inch) to several inches for certain materials. For example, steel expands about 0.000004 inches per degree Fahrenheit (0.000012 cm/°C). This means that if you heat one cubic inch of steel 100°F (38°C), it will increase in size by about 0.0004 inches (0.0012 cm). Other materials may expand much more or less depending on the type and composition. The amount of thermal expansion will also be different when a metal is heated from one side compared to when it is heated evenly throughout.

Which metal does not expand on heating?

Certain ceramics, such as quartz and alumina, do not expand when heated. While most metals will expand to some degree when heated, there are certain alloys that have been designed not to expand at all under extreme temperatures. These materials are often used in applications where thermal expansion is undesirable, such as turbine blades in jet engines or other components that must remain the same size under different temperatures.

How do you stretch metal with heat?

Stretching metal with heat, also known as hot working, is a process of using heat to make metal more malleable and easier to shape. This process can be used for various purposes such as forging tools, forming parts for machinery or art, or stretching metal into thin sheets. Hot working begins by heating the metal until it reaches its recrystallization temperature (the temperature at which the grains of the metal are reorganized). The heated metal is then placed in a hydraulic press where it is stretched between two dies. As pressure is applied, the metal stretches evenly along its length since all points on the surface are exposed to the same amount of pressure. The stretching continues until the desired length has been reached. The stretching of the metal affects its physical properties, such as its strength and hardness. Stretched metal typically has better ductility and improved tensile strength when compared to non-stretched metal.

Useful Video: Thermal Expansion Of Metals demo

Conclusion

In summary, metal does expand when heated. This phenomenon is known as thermal expansion and is caused by the increase in kinetic energy of the particles that make up the metal. Thermal expansion can be observed across different types of metals, including iron, aluminum, copper, and steel. As a result of this effect, materials may become distorted or deformed if they are not properly accounted for during construction or engineering processes. If you are working with metal and want to ensure accuracy, it is important to keep thermal expansion in mind when designing your project. It is also worth keeping an eye on your material’s temperature throughout any process involving heat transfer.

By understanding how metal expands when heated, you can reduce the risk of faulty products or structures due to thermal expansion. This knowledge also allows you to design and construct more efficient, reliable products in the future. Understanding how metal reacts to heat is an essential part of working with it effectively. With this information, you can ensure accuracy, safety, and effectiveness when working with metal materials.

References:

- https://www.metalsupermarkets.com/how-heating-metal-affects-its-properties/

- https://metalcutting.com/knowledge-center/heat-expansion-of-metals-and-the-summertime-blues/

- https://techiescientist.com/does-metal-expand-when-heated/

- https://homework.study.com/explanation/what-metal-expands-the-most-when-heated.html

- https://www.physlink.com/education/askexperts/ae40.cfm

- http://www4.hcmut.edu.vn/~huynhqlinh/olympicvl/tailieu/physlink_askexpert/ae40.cfm.htm