Choose the Best Metal Lathe Under $1000

Customer’s Choice: the Best Rated Metal Lathes Under $1000

19 users answered this survey. Please help us improve this review!

Metal lathes are a staple of any workshop. They can be used for a variety of tasks, from simple hobby projects to more advanced manufacturing. In this comprehensive guide, we will take a look at some of the best metal lathes under $1000 on the market today. We will answer some common questions and provide product reviews and useful tips to help you choose the right one for your needs. So whether you are a beginner just starting out or an experienced machinist looking for an upgrade, read on to find the perfect metal lathe for you!

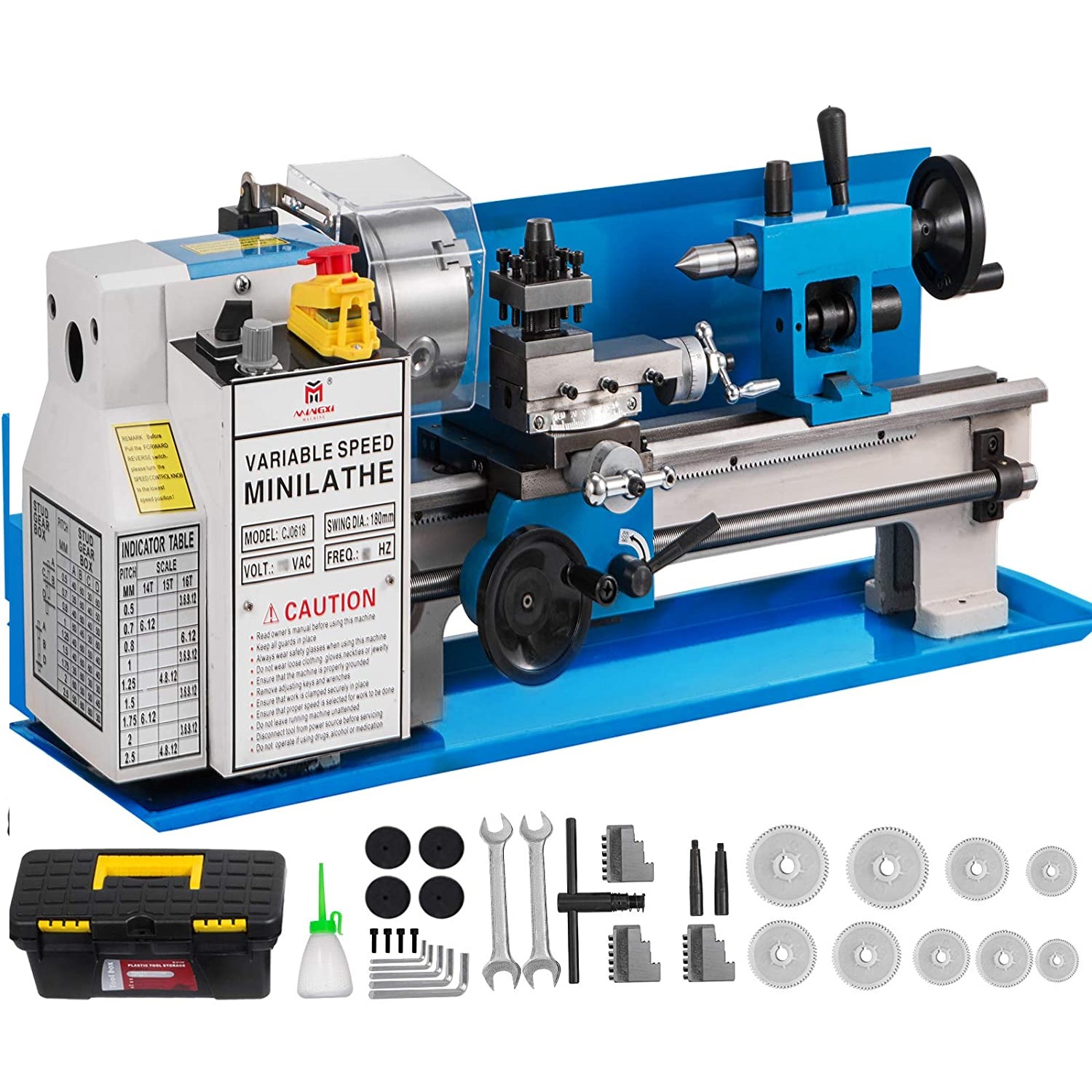

BestEquip Metal Lathe 7″ x 14″,Mini Metal Lathe

Looking for a versatile mini metal lathe that you can use for all sorts of projects? Look no further than the BestEquip Metal Lathe! This machine is perfect for hobbyists and beginners, with a variable speed range between 0 and 2500 RPM.

Looking for a versatile mini metal lathe that you can use for all sorts of projects? Look no further than the BestEquip Metal Lathe! This machine is perfect for hobbyists and beginners, with a variable speed range between 0 and 2500 RPM.

All things considered, this mini metal Lathe is a great choice for those who are looking for an affordable and reliable lathe. However, there are some things you should know before purchasing this particular model. First, it comes with no tool holders. This means you’ll need to find a place to store your tools when not in use. Additionally, the speed control is rough and the instructions are vague. As a result, this lathe may not be ideal for those who are new to using such equipment. Finally, the machine can be quite noisy and it’s poorly aligned, which can lead to low tolerance levels. Despite these drawbacks, the BestEquip Metal Lathe 7″ x 14″, is still a good choice for a starter and those on a budget.

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe

Precision is key when it comes to choosing the right mini metal lathe, and that’s exactly what you’ll get with the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe.

Precision is key when it comes to choosing the right mini metal lathe, and that’s exactly what you’ll get with the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe.

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. Sometimes you can get what you pay for. This lathe is a prime example of that. It’s cheaply made, difficult to set up, and won’t handle tougher projects because of the lack of power. But if you’re looking for something to do basic milling work on a budget, it could be a decent option. Just be prepared to deal with customer support when it inevitably falls apart.

Sherline 3.5″ x 8″ lathe, inch Metal Lathe

The Sherline 3.5″ x 8″ lathe is the perfect choice for anyone who wants to get into modeling! It’s compatible with a variety of accessories, and comes with a 48 page manual that will guide you through everything you need to know.

The Sherline 3.5″ x 8″ lathe is the perfect choice for anyone who wants to get into modeling! It’s compatible with a variety of accessories, and comes with a 48 page manual that will guide you through everything you need to know.

This lathe machine is perfect for anyone looking to get creative with metalworking, but be warned: its bore size of only .405 inches means it’s not suited for larger projects. And it’s not only the bore, the whole construction is small. So if you’re looking to turn some small pieces of metal into works of art, the Sherline 3.5″ x 8″ lathe is the perfect tool for you!

Mophorn Metal Lathe 7 x 12 Inch

If it’s a versatile metal lathe that you’re looking for, check out the Mophorn Metal Lathe 7 x 12 Inch. This sturdy machine is perfect for a wide range of applications, from light duty tasks to more heavy duty projects.

If it’s a versatile metal lathe that you’re looking for, check out the Mophorn Metal Lathe 7 x 12 Inch. This sturdy machine is perfect for a wide range of applications, from light duty tasks to more heavy duty projects.

The Mophorn Metal Lathe is a great option for those in the market for a cheap lathe. However, there are a few things you should know before making your purchase. First, the lathe is hard to fine tune and requires a lot of adjustments. Additionally, the tailstock is of poor quality and the tool holder may need to be replaced. Finally, your product can come with a few missing parts. Despite these drawbacks, the Mophorn Metal Lathe is still a great choice for those looking for a budget-friendly machine.

ele ELEOPTION Mini Metal Lathe Machine

Looking for a great metal lathe for hobby work? Look no further than the ele ELEOPTION Mini Metal Lathe Machine! This compact and lightweight lathe is perfect for working with soft wood, aluminum and plastic, and is ideal for anyone who wants to get started in metalworking.

Looking for a great metal lathe for hobby work? Look no further than the ele ELEOPTION Mini Metal Lathe Machine! This compact and lightweight lathe is perfect for working with soft wood, aluminum and plastic, and is ideal for anyone who wants to get started in metalworking.

However, ele ELEOPTION Mini Metal Lathe Machine is a terrible choice for anyone working with metal. It has poor precision and no speed control. Threading is also not possible with this machine. Additionally, the power supply is weak and needs replacement right out of the box, and the machine has vibration issues.

Buyers Guide

Metal Lathes and Their Role in Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large-scale structures. The term “metalworking” can refer to a wide range of activities, from large-scale manufacturing to small-scale art and jewelry making. Metal lathes are one of the most common tools used in metalworking, and they come in a wide variety of sizes and types, for example there are smaller mini lathes and bigger, sturdier machines.

Lathes are used to shape metal by rotating it against a cutting tool. This is done by holding the workpiece in place while it rotates on a spindle, and then moving the cutting tool along the workpiece to remove material.

Metal lathes are some of the most important tools in any metalworker’s arsenal. They are versatile machines that can be used for a wide variety of tasks, from shaping and cutting metal to creating smooth, precise finishes on surfaces. [1],[2]

What Metal Lathes Are There?

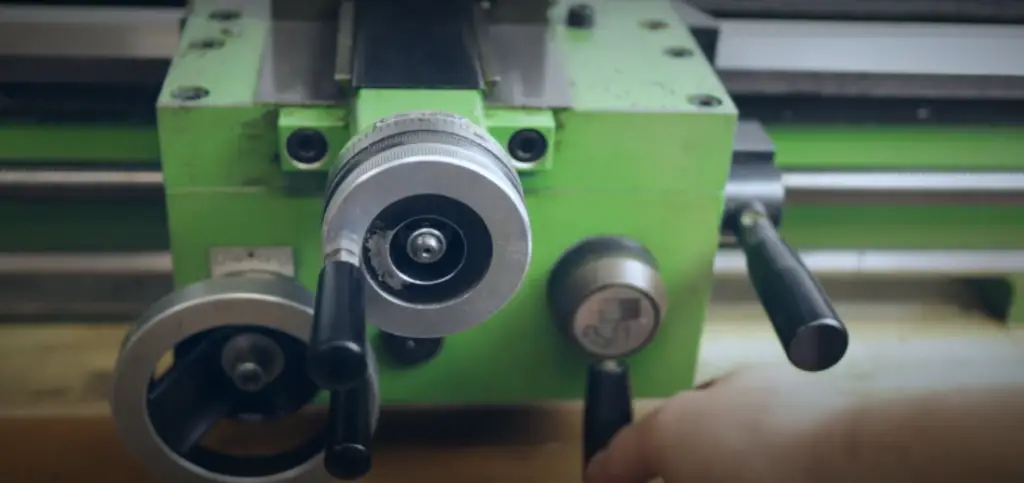

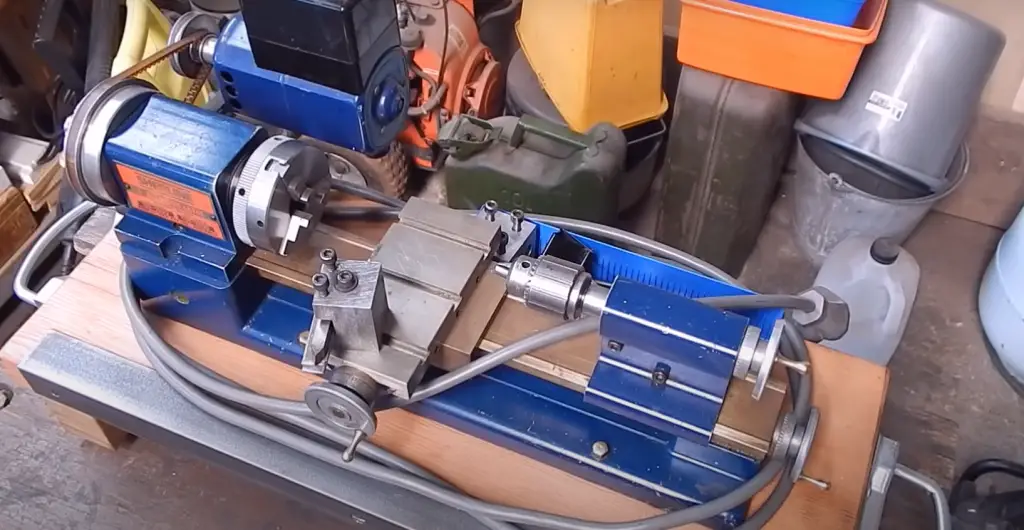

Metal lathes come in a variety of types. The most common type for DIYers is a benchtop lathe. These lathes are small and light enough to be placed on a workbench, making them perfect for small projects.

There are automated lathes as well. This kind of a machine doesn’t require manual control as it is computer-operated. The machine can be set to repeat the same task over and over again, making it perfect for mass production.

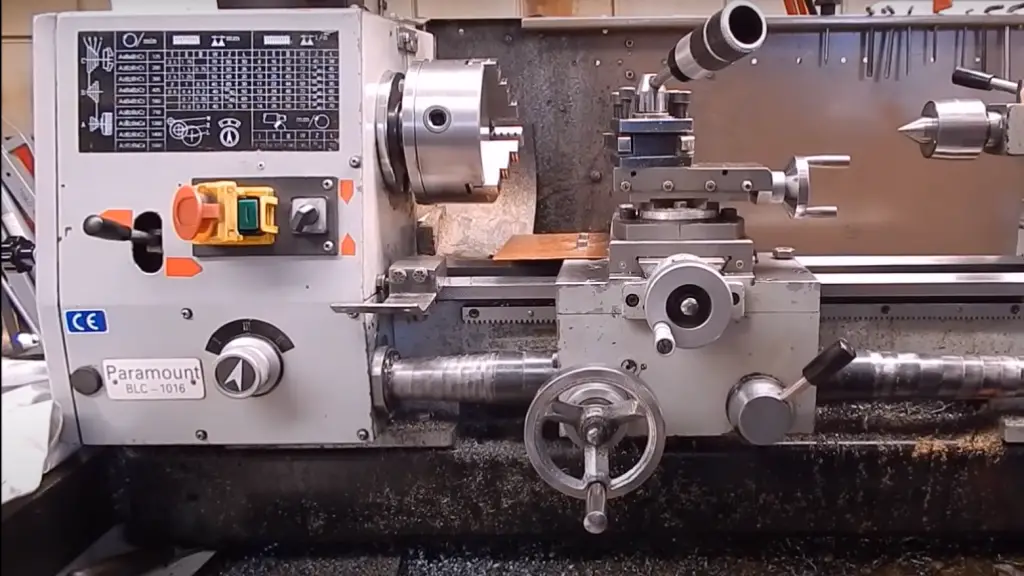

The last type of metal lathe is the engine lathe. This is the largest and most powerful type of metal lathe, and it is typically used in industrial settings. Engine lathes can handle very large projects, and they often have a number of specialized features that make them ideal for certain types of work. [3]

Benefits of Using Metal Lathes

Metal lathes offer a number of advantages over other types of machines.

They are durable and long-lasting

Metal lathes are built to last. They are made of heavy-duty materials that can withstand years of use. This makes them a wise investment for any shop or garage.

It’s easy to use them

They are also relatively easy to operate and maintain. With proper care, a metal lathe will provide years of trouble-free service.

They are highly versatile

Another advantage of metal lathes is their versatility. They can be used for a wide range of tasks, from cutting and shaping metal to creating smooth, precise finishes on surfaces.

They are beginner-friendly

Metal lathes are also a good choice for beginners. They come with all the necessary features and accessories to get started, and they are relatively easy to learn how to use.

While metal lathes are relatively easy to use, one shouldn’t forget the basic safety precautions. Always wear gloves and eye protection when operating a lathe, and be sure to follow the manufacturer’s instructions carefully. Your clothing should be proper for the job as well.

Don’t forget to check if both the workpiece and tools are properly secured before starting the machine. Not doing so can result in serious injury. [1],[2],[4]

Is it Possible to Find a Good Metal Lathe under $1000?

When it comes to their price, things can get difficult. Metal lathes can be expensive, and it might not be easy to find one that fits your budget. Luckily, it’s still possible to find a quality product for less than $1000!

The short answer is yes, it is possible to find a good metal lathe under $1000. However, it is important to keep in mind that there is a wide range of quality and features available in this price range.

As with any tool, you get what you pay for. In general, the more you spend on a metal lathe, the better the quality and features will be. That said, there are some great options available for less than $1000.

So, let’s take a look at some options first and get into depth about how to choose a good machine later. [5]

Buyers Guide for the Best Metal Lathes Under $1000

Now that you know what to look for in a metal lathe, it’s time to choose the best one for your needs. Here is a buyer’s guide with some of the best metal lathes under $1000!

Consider Your Budget

The first thing you need to do is consider your budget. Metal lathes can be expensive, so it’s important to set a budget before you start shopping. Once you know how much you’re willing to spend, you can narrow down your options and choose the best lathe for your needs.

If you’re on a tight budget, there are still some great options available. Just don’t expect to get a lathe filled with all the bells and whistles. Sometimes, you have to sacrifice some features in order to stay within your budget. [6],[8]

Wattage

The next thing you need to consider is the wattage. This is important because it will determine how powerful the lathe is. If you’re only going to be working with small projects, then you don’t need a powerful lathe. However, if you’re planning on working with larger projects, then you’ll need more power.

The wattage will also determine how fast the lathe can spin.

Otherwise, you can choose a lower wattage and save some money.Usually, it’s recommended to choose a lathe with at least 600 watts. This will ensure that you have enough power for most projects. Anything less than that might not be enough power for some projects. [7],[9]

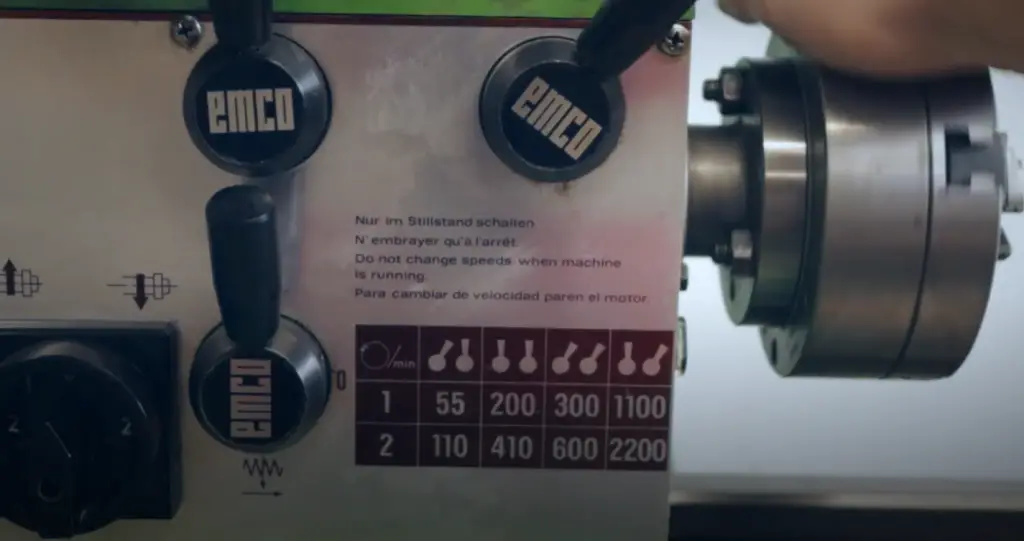

Spindle Speed

Another important consideration is the spindle speed. This is the speed at which the lathe can spin. The higher the spindle speed, the faster the lathe can work.

If you’re only going to be working with small projects, then you won’t need a high spindle speed. However, if you’re planning on working with larger projects, then you’ll need a faster spinning lathe.

Actually, most of the lathes in our list fit this criteria!

If you need a faster spinning lathe, then you’ll need to choose one with a higher RPM. Otherwise, you can choose a lower RPM and save some money. [7][9]

Functionality

Once you’ve considered your budget, it’s time to start thinking about functionality. What do you need your lathe to do? Are you looking for a specific feature? Make a list of must-haves before you start shopping. This will help you narrow down your options and find the best lathe for your needs.

There are many different features that metal lathes can offer, so it’s important to know what you need before you start shopping. If you’re not sure what you need, make a list of questions to ask yourself. This will help you figure out which features are most important to you.

But, since metalworking can be dangerous, you need to prioritize some safety features as well. A good metal lathe will have a number of safety features to help protect you from accidents. Look for a lathe with an emergency stop button, a power off switch, and a guard over the spindle. These are just a few of the most important safety features to look for in a metal lathe. [7],[9],[11]

Durability

Another important factor to consider is durability. Metal lathes are built to last, but some are better than others. Quality of the construction is important, as is the type of metal used. Some metals are more durable than others and can withstand more wear and tear.

Usually, you would want to choose a metal lathe that is made from cast iron. This material is very strong and durable, so it will last a long time. It is also resistant to vibration, which is important when you are using power tools.

Material of gears is also important. Steel gears are the best choice because they are strong and durable. Avoid plastic gears if you can because they are not as strong and can break easily.

Next come headstock bearings. These are what support the spindle and allow it to rotate. The best bearings are taper roller or ball bearings. Don’t go with regular bearings as they can wear out quickly.

A higher quality lathe that is well maintained can last decades. However, a lower quality lathe may only last a few years before it needs to be replaced.

Of course, how often you use the lathe also plays a role in how long it will last. If you use it every day, it will not last as long as if you only use it once in a while.

Regular maintenance is also important for prolonging the life of your metal lathe. Lubricate moving parts and clean off any dirt or debris to prevent wear and tear. Even cheaper lathes can last long if you take proper care of them! [5],[6],[7],[10]

Design of the lathe

Overall design is also essential to be considered when hunting for options. Designs can come in different shapes and sizes, but mostly depend on the features included with the lathe. Complicated design features can make the lathe more difficult to use, so if you’re a beginner, it’s best to choose a lathe with a simpler design. [8],[11]

Size of your workshop

The other factor you need to consider is the size of your workshop. Metal lathes come in a variety of sizes, so you need to make sure you choose one that will fit in your workspace. If you have a small workshop, then a mini metal lathe would be a good option for you.

If you have a larger workshop, then there are some full-size metal lathes that would be more suitable for your needs. You should also consider the type of projects you plan on using the lathe for. If you only plan on working with small pieces of metal, then a mini lathe would be sufficient. However, if you want to be able to work with larger pieces of metal, then a full-size lathe is essential for the job. Bigger lathes also have better precision rate and resist vibration better. [6],[8],[9],[11]

SOB and DBC

The next thing you need to consider is the Swing Over Bed and Distance Between Centers.

These two measurements will determine the size and shape of the projects you can create.

Swing Over Bed is the measurement from the center of the spindle to the bed. The Distance Between Centers is the measurement from the center of the spindle to the tailstock.

SOB is important because it determines the largest diameter project you can create. DBC is important because it determines the longest project you can make.

If you’re not sure what size projects you’ll be working on, it’s best to err on the side of caution and choose a lathe with a larger SOB and DBC. That way, you’ll have more flexibility and won’t have to upgrade to a larger lathe down the road.

Both the SOB and DBC are important considerations when choosing a metal lathe. You need to make sure that the lathe has enough space to accommodate the projects you want to create. [7],[9],[11]

Warranty

When you’re shopping for a metal lathe, it’s important to check the warranty. Some companies offer better warranties than others, so it’s worth checking before you make your purchase. A good warranty will cover any defects or problems that occur within a certain period of time.

Some manufacturers also offer extended warranties for an additional cost. These warranties are usually worth the extra money, since they’ll give you peace of mind in case something goes wrong with your lathe.

Once you’ve considered your budget and checked the warranty, it’s time to choose the best metal lathe for your needs! [8],[9]

FAQ

What size lathe do I need?

The size of lathe you need will depend on the projects you plan to use it for. If you’re primarily working on small projects, a mini lathe might be a good option for you. If you’re looking to tackle larger projects, a full-size lathe will be more suitable.

Keep in mind that the size of your workpieces will also dictate the size of lathe you need. Make sure to choose a lathe that can accommodate the largest piece you anticipate working with.

Finally, consider the space you have available in your shop or garage. Larger lathes can take up quite a bit of room, so if space is limited, make sure to pick accordingly.

When was the metal lathe invented?

Lathes have existed already during the Bronze age. The first lathes were turned by hand, powered by treadmills or windlasses operated manually. However, the prototype of a metal lathe we know now was created by Jacques de Vaucanson around 1751.

Today, there are many different types of lathes available on the market, from small benchtop models to large floor-standing models. Metal lathes can be used for a wide variety of projects, from creating intricate detailed workpieces to making large parts such as engine blocks or railway wheels. They are still an important part of many manufacturing processes and are used to create everything from car parts to medical implants.

Can a lathe reproduce itself?

A lathe can indeed be used to create another lathe. They are used to create the majority of parts for other lathes including the bed, carriage, and headstock.

What are 3 things you could make on the metal lathe?

Some things that you could make on a metal lathe are knives, bowls, and mechanical details. However, there are many more items that you could create depending on your creativity and the size of the lathe.

Useful Video: Best Metal Lathe Under 1000: Top Products In Your Budget

Conclusion

So, which is the best metal lathe for you? It depends on your needs and budget. We’ve provided a few different options depending on what you’re looking for. If you need something more heavy-duty that can handle bigger projects, go for the engine or automated metal lathes. If you have a smaller workshop and are working with a tighter budget, the benchtop or mini metal lathes might be a better fit. And no matter which model you choose, make sure to read the warranty information carefully so you know what is and isn’t covered. Happy turning!

References:

- https://www.ametals.com/post/what-is-a-lathe-and-how-does-it-work

- https://machinefanatic.com/what-does-a-lathe-do/

- https://machineryfuture.weebly.com/knowledge/lathe-machine-04

- https://littlemachineshop.com/images/gallery/info/MiniLatheUsersGuide.pdf

- https://tooltango.com/lathe/metal/under-1000/

- https://homemakerchic.com/best-metal-mini-lathe/

- https://handymansworld.net/best-mini-metal-lathes/

- https://www.architecturelab.net/best-metal-lathe/

- https://www.electronicshub.org/best-metal-lathes/

- https://www.sharpen-up.com/best-metal-lathe-money-top-5-reviewed/

- https://workgearz.com/best-metal-lathe-under-1000/