Choose the Best Benchtop Metal Lathe

Customer’s Choice: the Best Rated Benchtop Metal Lathes

616 users answered this survey. Please help us improve this review!

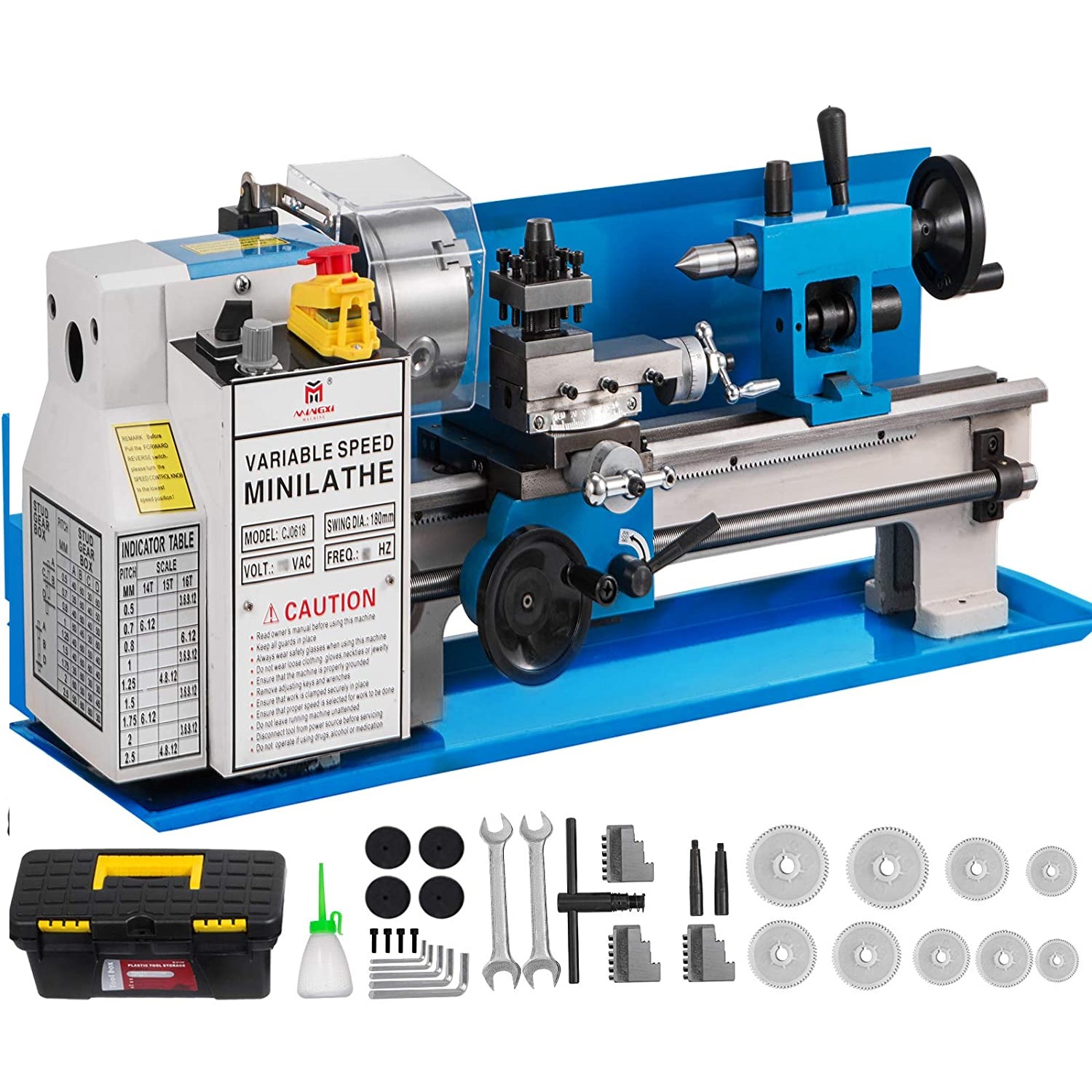

When it comes to metalworking, the benchtop metal lathe is a key tool. This versatile machine can be used for a variety of projects, from small repairs to large-scale fabrication. In order to get the most out of your benchtop metal lathe, it’s important to choose the right model for your needs. In this comprehensive guide, we will answer some common questions and review some of the best benchtop metal lathes on the market. With our advice, you’ll be able to find the perfect machine for your workshop!

BestEquip Metal Lathe 7″ x 14″,Mini Metal Lathe

Looking for a great lathe for all your hobby needs? Check out the BestEquip Metal Lathe 7″ x 14″! This affordable and sturdy lathe is perfect for any beginner or experienced hobbyist. The high-grade iron bed ensures durability and stability, while the speed ranges from 0 to 25000 RPM allow for precise and accurate cuts.

Looking for a great lathe for all your hobby needs? Check out the BestEquip Metal Lathe 7″ x 14″! This affordable and sturdy lathe is perfect for any beginner or experienced hobbyist. The high-grade iron bed ensures durability and stability, while the speed ranges from 0 to 25000 RPM allow for precise and accurate cuts.

BestEquip Metal Lathe may seem like a great option with its small size and low price tag. However, upon further inspection it’s clear that this product is flawed. The tools are poorly aligned and the switching speed can be rough, making it difficult to get the desired results. In addition, the build quality is cheap and there are no tool holders included. You will also need to spend some extra time trying to adjust the machine properly to achieve the desired performance.

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe

Looking for a versatile, yet affordable mini metal lathe? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This handy little lathe has a variable speed up to 2500 RPM, making it perfect for a wide range of projects.

Looking for a versatile, yet affordable mini metal lathe? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This handy little lathe has a variable speed up to 2500 RPM, making it perfect for a wide range of projects.

But this lathe does come with drawbacks. The Erie Tools machine is a cheaply made machine that is not suitable for demanding projects. The construction is loose and the manual is vague, making it difficult to use. Additionally, the power limits are low and the gears are made of plastic, which makes the machine less durable. Still, for simple jobs and light-duty work, this lathe is a good option.

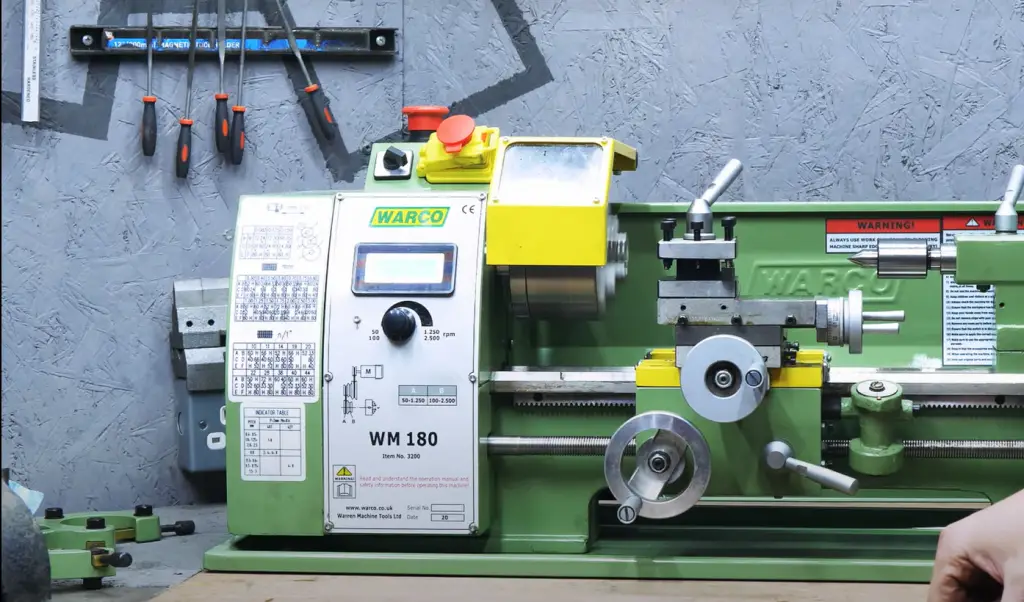

Grizzly Industrial G0768-8″ x 16″ Benchtop Lathe

Do you want to buy an affordable and powerful benchtop lathe? Look no further than the Grizzly Industrial G0768. This 8″ x 16″ lathe is perfect for beginners who want to get into woodturning, but it’s also powerful enough for more experienced users.

Do you want to buy an affordable and powerful benchtop lathe? Look no further than the Grizzly Industrial G0768. This 8″ x 16″ lathe is perfect for beginners who want to get into woodturning, but it’s also powerful enough for more experienced users.

If you’re looking for a basic lathe that can do light-duty work, the Grizzly Industrial G0768 might be a good fit. It has a poor porque and lack of rigidity, so consider that before starting to work on your project. But even then it’s perfect for hobbyists or people who need to do occasional work with metal. The compound rest is poorly designed and changing the belt can be a hassle, but overall this machine is easy to use and economical.

TECHTONGDA 8X31” Precision Metal Bench Lathe

Looking for a versatile and powerful metal lathe? Look no further than the TECHTONGDA 8X31” Precision Metal Bench Lathe. This top-of-the-line lathe can be used for a wide variety of tasks, including turning, drilling and threading.

Looking for a versatile and powerful metal lathe? Look no further than the TECHTONGDA 8X31” Precision Metal Bench Lathe. This top-of-the-line lathe can be used for a wide variety of tasks, including turning, drilling and threading.

There are some downsides to this lathe however. It doesn’t have imperial dials, only metric. So if you aren’t familiar with these units, you will be left confused. This lathe doesn’t have a rotation direction switch, so you’ll need to adjust it often. And don’t forget to tighten the chuck properly; it loosens easily. Other than that, this lathe is great for precision metalworking.

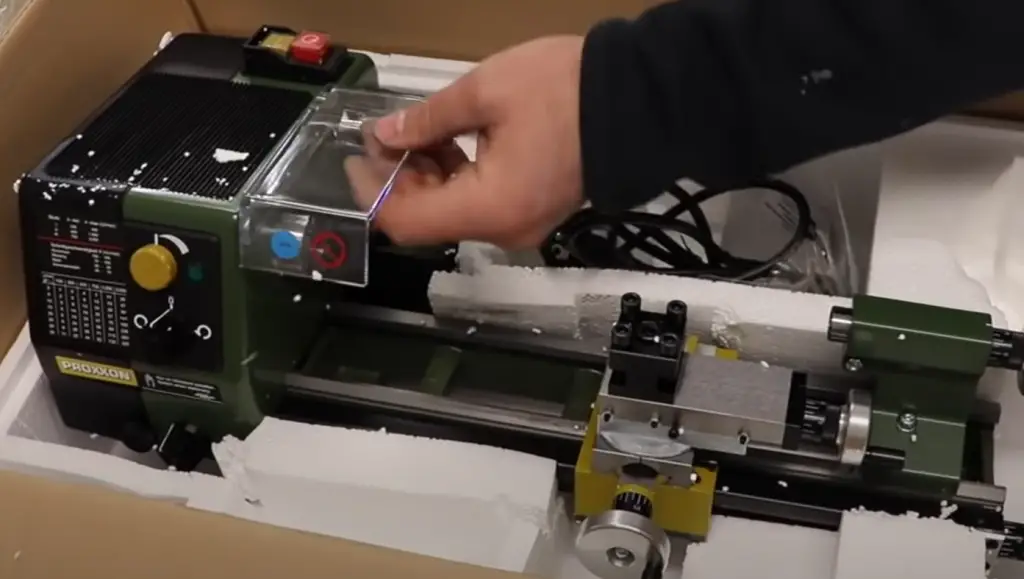

Sherline 3.5″ x 8″ lathe, inch Lathe

Introducing the Sherline 3.5″ x 8″ lathe! It’s a small, versatile lathe that can handle both inch and metric measurements! It’s easy to set up and operate, and comes with a detailed colored manual that makes it simple to get started.

Introducing the Sherline 3.5″ x 8″ lathe! It’s a small, versatile lathe that can handle both inch and metric measurements! It’s easy to set up and operate, and comes with a detailed colored manual that makes it simple to get started.

So, if you’re looking for a small lathe that can handle minor projects, the Sherline 3.5″ x 8″ lathe is a great option. With a bore of only .405 inches, it’s not meant for major projects, but it’s perfect for small jobs. The compact size makes it easy to store and transport, and the sturdy construction ensures years of reliable use.

Buyers Guide

The Definition of a Metal Lathe

A metal lathe is a machine tool that removes material from workpieces by abrasion, while they are rotated against cutting tools. This process is used to create parts with intricate shapes and detailed features. Metal lathes can be operated manually or automatically.

Lathes are old tools that had a major role in shaping the modern world. They were first used in ancient Egypt and China for art and jewelry making. In the 1700s, industrial lathes were developed to mass-produce parts for clocks and other devices.

Today, metal lathes are much smaller and more versatile. They are commonly used in machine shops and garages for a variety of projects, including machining parts, creating threads, and shaping objects with irregular surfaces.

There are several different types of metal lathes available on the market today. Let’s discuss these in detail! [1],[2],[3]

Different Types of Metal Lathes

One of the most common types of metal lathes is the engine lathe. This machine is designed for heavy duty tasks and can handle large workpieces. Engine lathes are typically used in industrial settings, such as factories and machine shops.

Another popular type of metal lathe is the automatic lathe. This machine is similar to the engine lathe but is operated by a computer instead of a human operator. Automatic lathes are faster and more precise than manual lathes, making them ideal for complicated projects.

Next comes the tool room metal lathes. These lathes are smaller and more precise than engine lathes. They are commonly used in shops that create parts for other machines.

Finally, we have benchtop metal lathes. As the name suggests, these machines are designed to be used on a benchtop or table. Benchtop metal lathes are the most compact and portable type of lathe, and they come in different sizes, like midi and mini lathes. They are less powerful than engine lathes but offer more flexibility in terms of the projects they can be used for. [3]

How Many Benefits Does a Benchtop Metal Lathe Have?

A benchtop metal lathe is a versatile machine that can be used for a variety of projects. This makes it an ideal tool for hobbyists, DIYers, and small businesses.

Some of the benefits of using a benchtop metal lathe include:

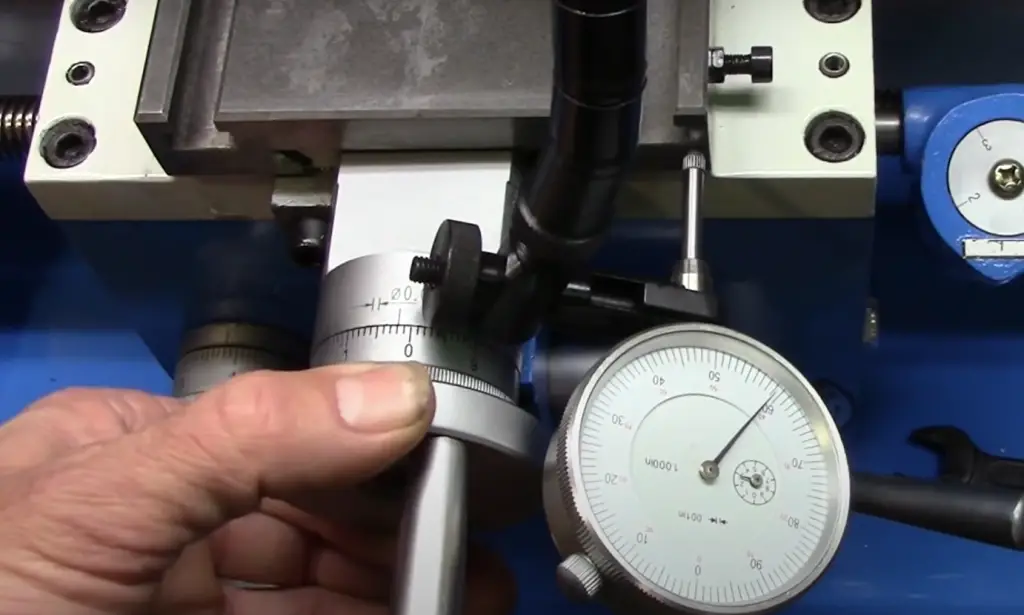

Increased accuracy

A benchtop lathe is a precision tool that can create detailed and accurate parts for all your hobbyist needs. This is due to the fact that benchtop lathes are designed for small projects. The smaller size of the workpiece means that there is less room for error.

Ideal for beginners and DIY enthusiasts

A benchtop lathe is a great choice for those just starting out in metalworking. These machines are easy to use and offer a wide range of features and capabilities.

Greater flexibility

Thanks to their compact size, benchtop metal lathes offer greater flexibility than larger machines. They can be used in tight spaces and easily moved around the workshop. This makes them ideal for small businesses and hobbyists who don’t have a lot of space to work with.

Enhanced safety

Benchtop metal lathes are also safer to use than larger machines. They come with numerous safety features that protect you from injuries while working.

Cost-effectiveness

Benchtop lathes are a cost-effective solution for those who want to add a metal lathe to their workshop. They are less expensive than larger machines and offer the same level of precision and accuracy.

Structure of a Metal Lathe

All lathes, including benchtop metal lathes, have three main components attached to the bed: the headstock, the carriage, and the tailstock.

The bed is the foundation of the lathe and provides support for the workpiece. The bed is usually made from cast iron or steel and has a smooth surface to prevent vibrations.

Most benchtop metal lathes have a fixed bed, which means it cannot be moved. This can be seen as a disadvantage because it limits the size of the workpiece that can be machined. However, it also makes the machine more stable, which results in increased accuracy.

The headstock is located at the front of the machine and houses the motor. The headstock is responsible for holding and rotating the workpiece. It also has a number of different attachments, such as chucks and Morse tapers, that can be used to secure the workpiece.

The carriage is attached to the headstock and slides along the bed of the lathe. The carriage contains all of the cutting tools, such as drill bits and end mills.

The tailstock is located at the opposite end of the lathe from the headstock. It supports the free end of the workpiece and allows it to rotate freely. The tailstock can also be used to apply pressure to the workpiece while machining, which helps to prevent it from moving or vibrating. Tailstocks come in different sizes and styles, depending on the type of lathe you have.

This simple structure is one of the reasons why benchtop lathes are so versatile. With just a few attachments, they can be used for a variety of different projects.

Metal lathes can also be equipped with a number of accessories, such as chucks, tool holders, steady rests, and follow rests. These accessories allow you to customize your lathe to suit your specific needs. [1]

Now that we have a better understanding of what a metal lathe is and how it works, let’s take a look at some of the best benchtop metal lathes on the market today!

Buyers Guide for the Best Benchtop Metal Lathes

Now that you know what to look for in a benchtop lathe, it’s time to choose the best one for your needs. Here is a list of all the important factors you should consider before making your purchase.

Size

The first thing you need to consider is the size of your lathe. You need to make sure that the lathe you choose is big enough for the projects you want to use it for. If you only plan on using it for small projects, then a smaller lathe will be just fine. However, if you plan on using it for larger projects, then you’ll need to get a bigger lathe.

From the size factor, the portability question arises. If you only plan on using your lathe in one spot, then size isn’t as big of a deal. However, if you want to be able to move your lathe around, then you’ll need to get a smaller one. [4],[6],[7]

Spindle Speed

The next factor to consider is the spindle speed. This is how fast the spindle turns. The faster the spindle turns, the more power it has.

Make sure that you get a lathe with a variable speed so you can adjust it depending on the project you’re working on.Wattage

The wattage is one of the most important factors to consider when choosing a benchtop lathe. The higher the wattage, the more powerful the motor will be. If you plan on using your lathe for heavy-duty projects, you’ll need a machine with a high wattage. But if you only plan on using it for light-duty tasks, a lower wattage will suffice.

Usually lathes have a motor between 600 and 1200 watts. Anything above that is considered a heavy-duty lathe.

When it comes to horsepower, most benchtop lathes have between 600 and 1200 watts. The more powerful a machine is, the more expensive it will be. Most hobbyists or DIYers won’t need a lathe with 1000 watts, so you may not go as far as purchasing one of these. [5],[7]

Price

The price is one of the most important factors to consider when buying a benchtop lathe. You want to make sure you get the best value for your money. There are a variety of different prices depending on the features and quality of the lathe.

A good lathe will cost you between $600 and $1000. If you want a top-of-the-line lathe with all the bells and whistles, you can expect to pay upwards of $2000.

Keep in mind that the price is not always indicative of quality. There are some cheaper lathes that perform just as well as the more expensive ones. It really depends on your specific needs and budget. [4],[6]

Easiness of Use

The best benchtop metal lathes are easy to use and have intuitive controls. You should be able to set up the machine without any difficulty and get it running smoothly. Look for a lathe that comes with a detailed manual or video instructions.

Operating the lathe should be straightforward, with clear labels on all the controls. A good benchtop lathe will also have safety features such as an emergency stop button in case of accidents.

Warranty

Last but not least valuable detail to consider when choosing a benchtop lathe is the warranty. Many companies offer a limited warranty on their products, so it’s important to read the fine print before making your purchase. Some companies also offer extended warranties for an additional fee.

There are several things you should keep in mind when considering a benchtop lathe’s warranty. First, make sure the company offers a money-back guarantee or exchange policy in case you’re not satisfied with the product. Second, find out how long the warranty lasts and what types of damages are covered. And finally, make sure you understand the company’s return policy in case you need to return or exchange the product. [6],[7]

Availability of Extra Features

When browsing your options, you should always check whether or not it has extra features that can come in handy. Some lathes come with digital readouts, which can be a great help when trying to achieve precise results. Others have programmable spindle speeds, which can make your life much easier if you often need to change the speed while working. And some even come with built-in coolant systems, which can keep your workpiece from overheating during long sessions.

Safety features are another important aspect to look for.

And overload protection is also a valuable feature, as it can help you avoid damaging your lathe by overworking it.Extra features like these can be very useful, so it’s important to decide which ones are most important to you before making your purchase. If you only ever work with small pieces of metal, then a lathe with built-in coolant system might not be worth the extra money. But if you often need to change the spindle speed while working, then a lathe with programmable spindle speeds could save you a lot of time and frustration.

In the end, it all comes down to your needs and preferences. only you can decide which features are most important to you.[4],[5],[8]

Metrics vs Imperial

The first thing you need to decide is whether you want a lathe that uses metric or imperial measurements. If you’re not familiar with the difference, metric measurements are used in most of the world, while imperial measurements are used in the United States. This won’t affect the performance whatsoever and is more about your own convenience. [9]

Quality of the Headstock Bearings

The headstock bearings are one of the most important parts of the lathe. They support the spindle and must be able to withstand a lot of wear and tear. When choosing a benchtop lathe, make sure to pick one with high-quality headstock bearings.

Never choose a machine with plain bearings. These are not as durable and will need to be replaced more often. If you can, choose a lathe with tapered roller bearings or ball bearings. These are the most durable and can handle a lot of abuse. [8]

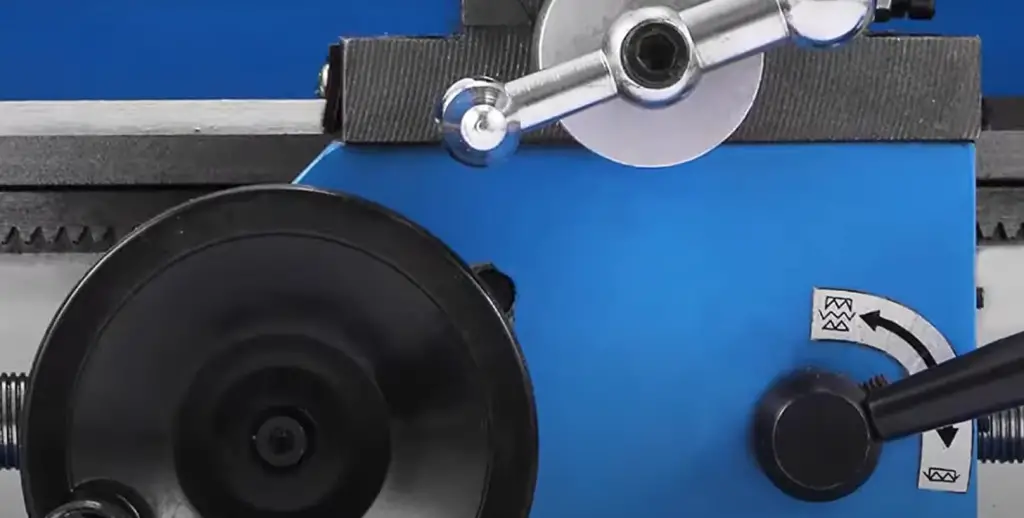

Type of Tool Posts

The type of tool post you need will depend on the project you’re working on. There are QCTP, four-way tool posts and lantern tool posts. If you’re only doing light work, then a QCTP will suffice.

Quick change tool posts are the most popular type of tool post. They’re easy to use and allow you to quickly change between tools and we prefer going with these if possible. [9]FAQ

What makes the best bench lathe?

The best bench lathe is the one that fits your specific needs the best. There are many different types and models of bench lathes on the market, so it’s important to do your research before making a purchase.

Good lathe will have a sturdy build, precision ground ways, and a powerful motor. It will also be easy to operate and have a wide range of features.

How do you use a benchtop metal lathe?

Using a benchtop metal lathe is easy once you know the basics. In order to use one, you’ll need to set up your work area, choose the right tools, and be familiar with the different parts of the lathe.

The first step is to set up your work area. You’ll need a level surface on which to place your lathe, as well as enough space around it to move freely. You’ll also need to make sure that there’s adequate lighting so that you can see what you’re doing.

Next, you’ll need to choose the right tools for the job. The most important tool for using a benchtop metal lathe is the cutting tool, which will be used to remove material from the workpiece.

Once you have your work area set up and your tools selected, you’ll need to become familiar with the different parts of the lathe. You definitely need to read a manual to understand how your specific model works. Just remember to clean it well afterwards!

Using a benchtop metal lathe is a great way to create precise and accurate pieces. With a little practice, you can start making beautiful works of art.

Are metal lathes essential?

No, but they make working with metal much easier and more precise. If you’re planning on doing any serious work with metal, a lathe is an invaluable tool to have in your shop.

What is better: a mill or a lathe?

This is a difficult question to answer. It depends on what you’re trying to do and what your budget is. If you’re looking to do very precise work, then a mill might be better. However, if you’re working on larger projects or projects that require more power, then a lathe might be the better option.

Useful Video: Grizzly G0768 – Quick Change Tool Post (QCTP) and Top Nut install

Conclusion

So, there you have it. A quick guide to the different types of metal lathes and what each can be used for. If you’re in the market for a new lathe or are just curious about all the different kinds available on the market, hopefully this article has helped clear some things up. There are engines, computer powered and even automated lathes, but the type that is relevant to us are benchtop models, and they are still widely used now!

There are a variety of factors you need to take into account, such as budget, size of the lathe, amount of features, easiness of use and of course the motor power. We hope our metal lathe comparison chart and buyer’s guide will help make your decision easier. And remember, always go with a model that has a good warranty – you never know when something might go wrong. Thanks for reading and happy metalworking!

References:

- https://www.ametals.com/post/what-is-a-lathe-and-how-does-it-work

- https://machinefanatic.com/what-does-a-lathe-do/

- https://machineryfuture.weebly.com/knowledge/lathe-machine-04

- https://homemakerchic.com/best-metal-mini-lathe/

- https://handymansworld.net/best-mini-metal-lathes/

- https://www.architecturelab.net/best-metal-lathe/#Mini_Metal_Lathe_vs_Metal_Lathe

- https://www.electronicshub.org/best-metal-lathes/

- https://www.sharpen-up.com/best-metal-lathe-money-top-5-reviewed/

- https://www.theruggedrooster.com/best-benchtop-metal-lathe/