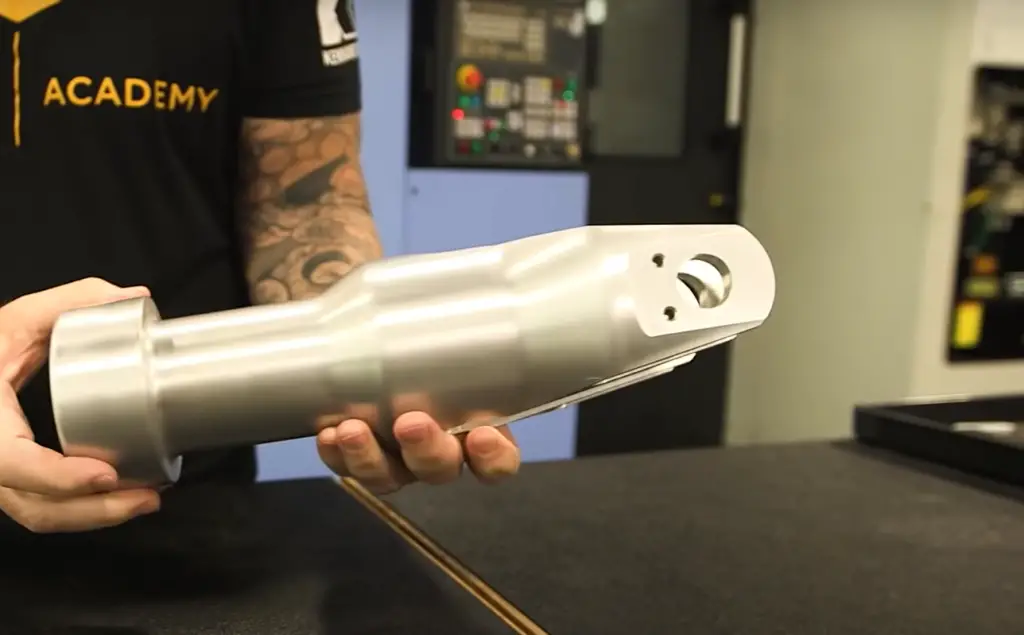

Are you looking for a way to machine titanium? Titanium is one of the most desirable metals used in manufacturing because of its high strength and low weight properties, making it an ideal material for use in aerospace and automotive applications. But how do you actually go about machining titanium components?

In this blog post, we’ll cover the basics of machining titanium, so that you can confidently create precise parts with your own machines. Knowing what tools and materials to use will help make your production process much smoother! So keep reading to find out more – let’s dive into learning how to machine titanium today!

Titanium Varieties

There are different types of titanium. Some examples are Grade 5 and Grade 4. Each type is different. For example, Grade 5 is the most widely used and has good ductility.

This means it can be pulled or stretched into shapes without breaking.

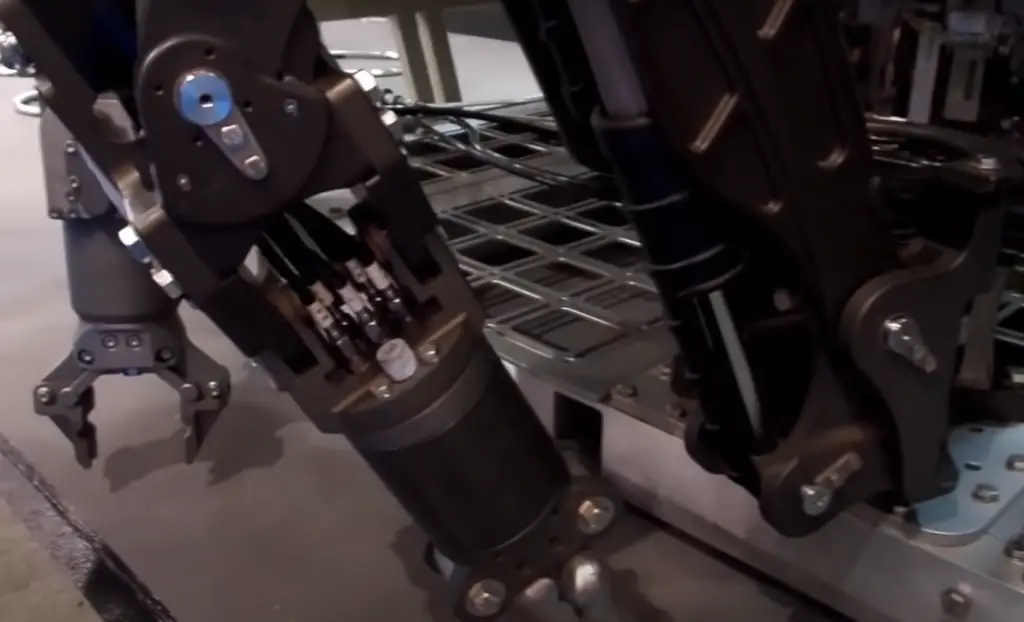

Tools & Equipment Needed

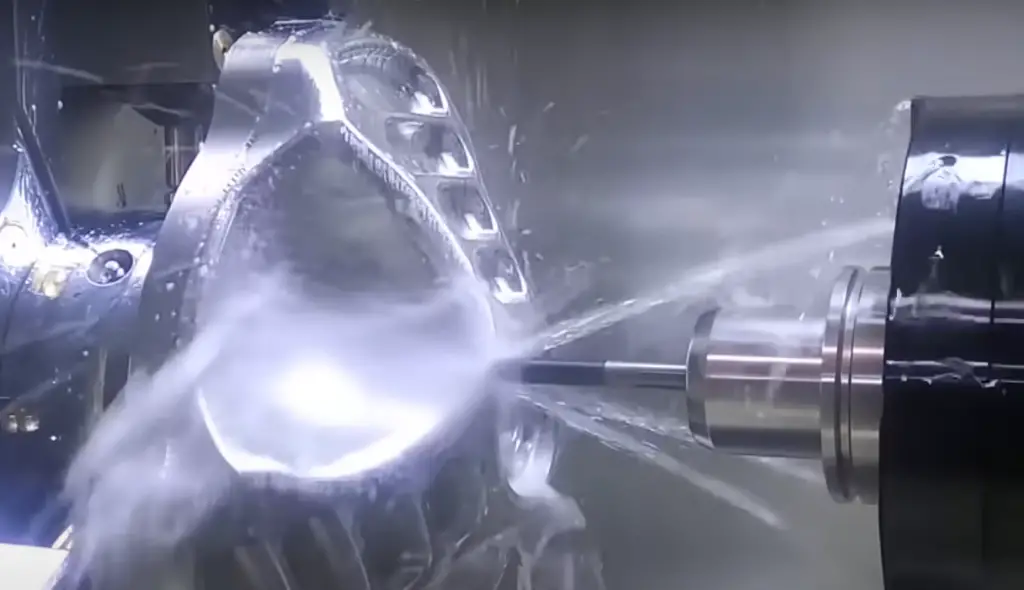

The most important tool is a milling machine that can handle the material. Milling machines with carbide cutting tools are best for machining titanium, as they will last longer and cut cleaner. It’s also important to choose the right cutting speed and feed rate so that you get an even finish on your part.

For smaller and more intricate components, you may need a lathe or drill press to make sure the part is precise and free of defects. These tools come in different sizes so that you can work with titanium of any thickness.

You should also consider using coolants like cutting oil to keep your equipment running smoothly and reduce wear on titanium.

Titanium Concerns

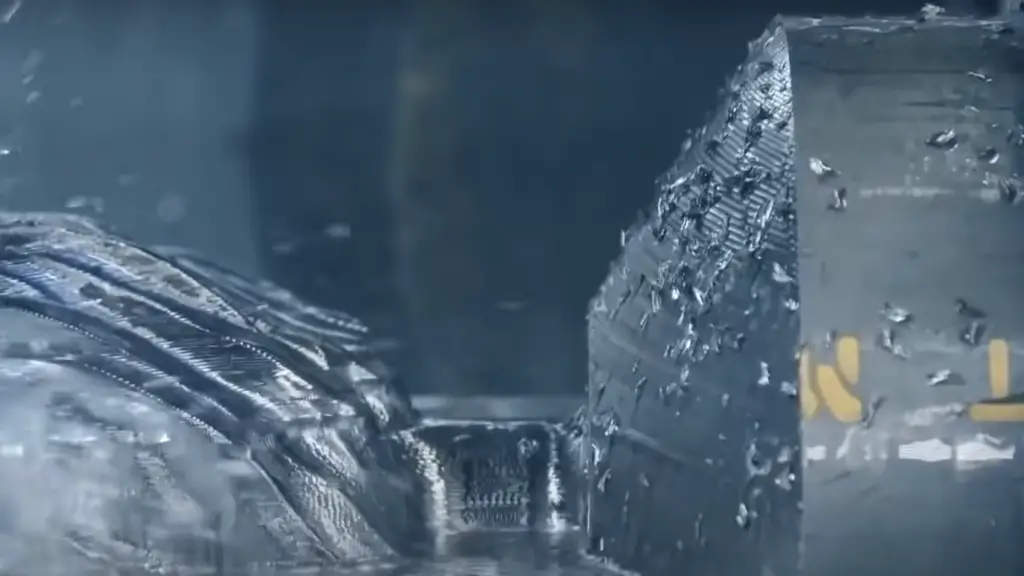

When machining titanium, it is important to consider the material’s high heat conductivity. You need to cool your cutting tools often to prevent damaging the part or making a mess of your shop floor.

A good way to do this is by using water-soluble coolants such as emulsions and soluble oils.

Titanium produces burrs and chips when machined. To avoid these, you can use a chip wringer to collect the chips and scraps that come off your machine. This will help keep your workspace clean and safe so that you can work more efficiently.

Workholding

It is important to make sure that your titanium part does not move while you are cutting it. This will help you avoid accidents and damage to the part.

You can use clamps or jigs to secure the part in place.

Heat Generation

Titanium is a metal that gets hot when it is being cut. This can be dangerous to you and the part, so it is important to monitor the machine’s temperature often. If the machine gets too hot, then you should stop and let it cool down before continuing with machining operations.

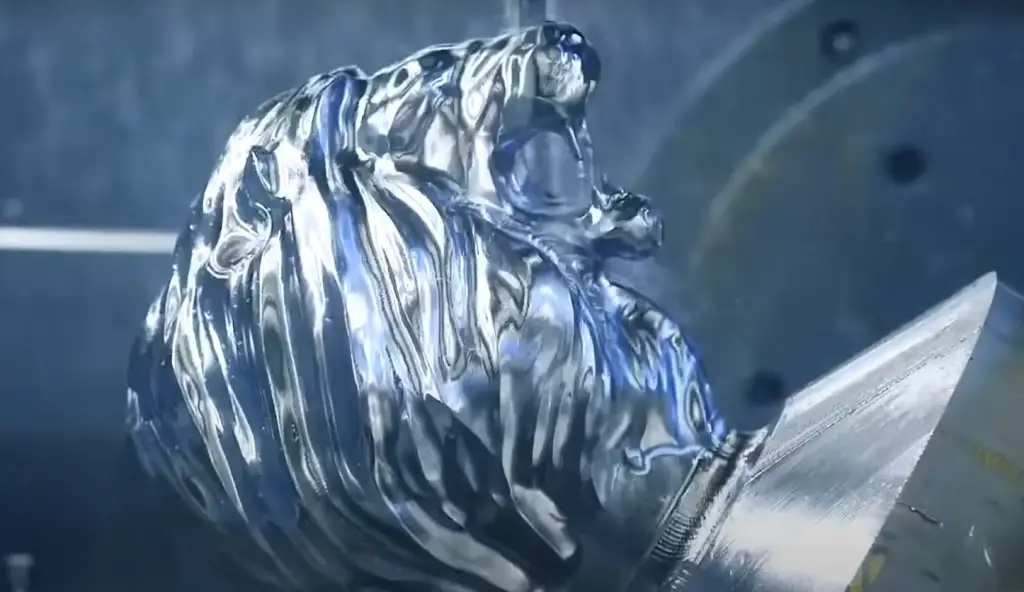

Galling and Built-Up Edge

When machining titanium, you may encounter galling and built-up edges. Galling is when two surfaces rub together and become stuck or welded. To avoid this, use a high-speed steel cutting tool with a sharp edge.

Built-up edges occur when the same part of the tool continuously cuts the material; this can be prevented with frequent tool changes.

Titanium Solutions

Machining titanium is not a task for the faint of heart, but with the right tools and techniques, you can successfully create parts from this strong and lightweight material.

Make sure to use the correct cutting speed, feed rate, coolants, jigs, and other appropriate materials to ensure that your titanium components are precise and free of defects. [1]

Machining Strategies for Titanium

Avoiding Jarring Engages and Disengages

When working with titanium, it is important to make sure that the cutting tool doesn’t stop and start suddenly.

This can cause problems with the surface of the part. To prevent this, use a steady feed rate and make sure there are no sudden changes in direction or speed.

Plunge Milling

Plunge milling is a technique used to cut titanium with a rotating end mill. This method works by plunging the cutting tool into the material in short, controlled movements. This helps reduce heat and prevents built-up edges from forming on the part.

Low Radial Engagement with Peel Milling

Peel milling is a way to machine titanium using a rotating end mill. This technique helps reduce heat buildup and wear on the cutting tool by using shallow radial engagement. This helps preserve accuracy while machining intricate components out of titanium.

High-Feed Milling

The high-feed milling technique uses a shallow depth of cut and a high feed rate to machine titanium. This method helps reduce the amount of heat that builds up, makes the surface finish better, and increases the tool life.

It also reduces the time it takes to finish a machining job, making it perfect for large production runs.

Varying Depth of Cut and Spindle Speed

It is effective to use different depths of cut and spindle speeds when machining titanium. If a high-speed finish is needed, then use a low depth of cut at a high spindle speed.

Alternatively, if the surface finish doesn’t need to be perfect, then you can use a deeper depth of cut with a slower spindle speed. Doing this will help reduce the amount of heat generated and wear on the cutting tool. [2]

Thin Feature 8x Rule

When machining thin features in titanium, it is important to use a tool with an 8x diameter ratio. This ensures that the surface finish of the part is not compromised and that the tool will remain sharp longer.

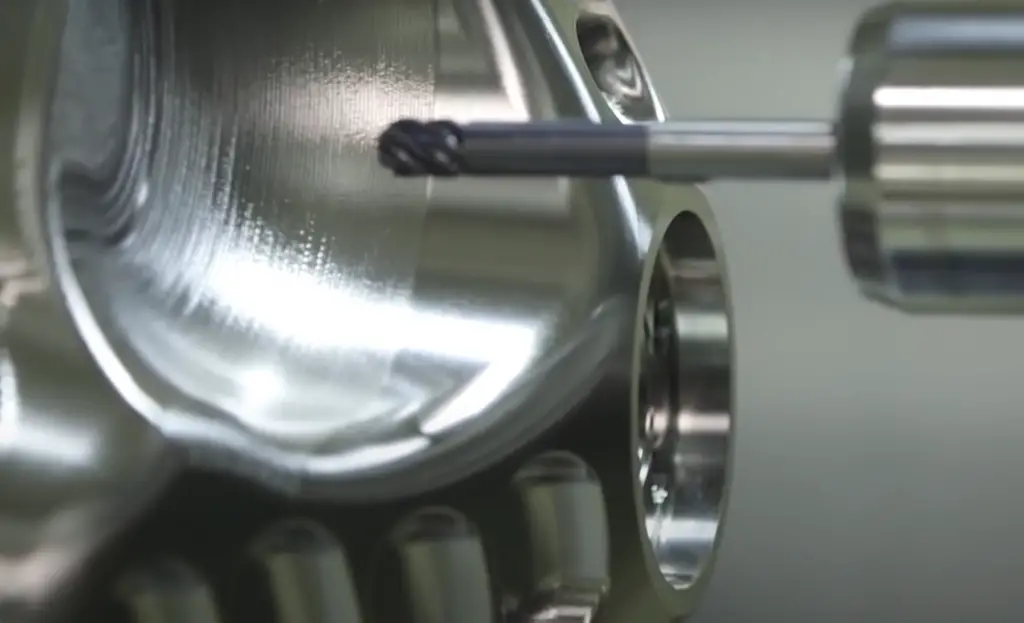

Turning and Facing

Turning and facing are two ways to machine titanium. Turning means the cutting tool moves around the part in one revolution. Facing removes material from the end of a part. These techniques can be used to machine intricate features in titanium parts.

Selecting Appropriate Cutters

Helix Angle and Flutes

When you are trying to figure out which tool to use to cut something on a machine, it is important to think about the helix angle and the flutes. The helix angle is how quickly the chips (pieces) are taken away from the cut.

It also decides how strong each chip is. More flutes means that the chips will be taken away more effectively. This helps reduce heat and makes the surface finish better.

Rake Angle

The rake angle is the angle of the cutting tool. It determines how much material can be removed with each pass.

A positive rake angle (one that is higher than the center line) helps reduce cutting forces, while a negative rake angle (one lower than the center line) increases them. Depending on your application, you may need to use a different rake angle.

Cutting Edge Geometry

The cutting edge geometry of the tool also has an effect on how titanium is machined. It can be sharpened, honed, or relieved depending on the type of cut you need. Sharp edges are better suited for roughing operations while honed edges are better for finishing.

Variable Pitch End Mill

If your project requires machining a complex shape, then using a variable pitch end mill can be helpful.

This type of tool has teeth with varying depths and spacing, which helps to reduce chatter and vibration when cutting titanium parts. It also provides a smoother surface finish than traditional end mills.

Variable Helix

A variable helix is another type of tool that can be used to machine titanium. This type of cutting tool has teeth with varying spacing, which helps reduce the vibration and chatter when machining titanium parts. It also provides a better surface finish than traditional end mills.

Tool Accuracy

It is important to have a cutting tool that is accurate. If the cutting tool is accurate, it will generate less heat and wear out less quickly.

If you can, use a higher-quality cutting tool for extended periods of time. This will help improve the surface finish and give better results overall.

Number of Flutes

The number of flutes on a cutting tool affects how well it machines titanium. More flutes helps to reduce the heat and vibration during machining, while fewer flutes can provide a better surface finish.

When choosing a tool for your application, think about the number of flutes that will work best.

Coatings

Tool coatings can also be used to improve the performance of your tool when machining titanium. Coatings such as diamond or TiAlN can help reduce friction and wear, which helps extend the life of the tool and improves performance.

Machine Requirements

Depending on what you are making, you may need to use a different type of machine. Some machines are better for making large parts. CNC machines are more precise than manual ones.

You also need to think about the speed of the machine, how fast it moves, and other things that can affect how well titanium is machined.

Rigidity

The rigidity of the machine is also important. Titanium can be difficult to machine, so having a rigid setup is essential. If the machine has too much flex, it will produce an inconsistent finish and can cause damage to the tool or part.

Coolant and Lubricants

If you use coolant and lubricants when machining titanium, it will help reduce heat and make your tool last longer.

But you have to be careful about which coolant or lubricant you use.

Some chemicals can ruin titanium or make it corrode. Also, once you finish machining, clean up any leftover coolant or lubricant.

Power

When you are using a machine to cut titanium, you need to make sure that the machine has enough power. Titanium is a strong material and it needs more power than other materials.

If your machine does not have enough power, it will damage the tool or part and it will not work as well. Always check the specifications of your machine before beginning any project.

Safety Precautions

Always make sure to follow safety precautions when machining titanium.

Use eye protection, gloves, and other protective gear if necessary. Keep your work area clean and organised to reduce the risk of accidents or injuries.

Production Tips

Here are some useful tips to consider before starting your project:

- Use the right cutting tool for your application

- Choose a tool with adequate accuracy

- Select the appropriate number of flutes

- Consider using coatings to improve performance

- Make sure your machine has enough power

FAQ

Is titanium hard to machine?

Yes, titanium can be difficult to machine. The material is strong and heat resistant, so it requires more power than other materials. It also produces a lot of vibration and chatter, so using cutting tools with variable helix teeth can help reduce this.

What type of machine is best for machining titanium?

The best type of machine for machining titanium is a CNC machine.

CNC machines are more precise and can handle the material better than manual machines. They also have higher speeds, which makes them well suited for making large parts.

What type of coolant or lubricant should I use when machining titanium?

There are several types of coolants and lubricants you can use when machining titanium. However, some of them can damage the material or make it corrode, so you have to be careful about which one you choose.

It is best to consult with a professional before selecting a coolant or lubricant for your application.

Will I need more power to machine titanium?

Yes, titanium requires more power than other materials. Make sure your machine is powerful enough for the job or it can damage the tool and part. Check the specifications of your machine before beginning any project.

What do you need to machine titanium?

To machine titanium, you will need the right cutting tools, coolant or lubricants, a powerful machine, and safety equipment. You also need to make sure that your setup is rigid enough for the job.

How to machine titanium safely?

When machining titanium, you need to follow some safety rules. You should wear eye protection, gloves and other gear if you have it. Keep your work area clean and organised to reduce the risk of accidents or getting hurt. Lastly, clean up any leftover coolant or lubricants after you finish the job.

Is titanium easily machinable?

Yes, titanium can be machined easily with the right setup. Make sure to use the appropriate cutting tools and coolant or lubricants, and have a powerful enough machine for the job. With the correct setup, titanium can be machined just as accurately as other materials.

Can you CNC machine titanium?

Yes, CNC machines are well suited for machining titanium because of their accuracy and speed. They also have higher power requirements than manual machines, so they can handle the material better. However, always make sure to follow safety precautions when machining titanium.

Can you machine titanium on a lathe?

Yes, you can machine titanium on a lathe. However, it requires more power than other materials and generates a lot of vibration and chatter.

Using cutting tools with variable helix teeth can help reduce this. Also, make sure that your lathe is powerful enough for the job before beginning any project.

What is the best way to machine titanium?

The best way to machine titanium is to use a CNC machine and the right cutting tools. Make sure your setup is strong enough for the job, and use coolant or lubricants if needed.

You should also wear eye protection and other safety gear when machining titanium. Finally, clean up any leftover coolant or lubricants after you finish the job.

If you want to do a better job machining titanium, use coatings on your cutting tools. Diamond, nitride and TiN coating can help reduce wear and tear, increase tool life and improve surface finish of the part. Be sure to choose a coating that will work well with titanium.

What cutting tools should I use for titanium?

To cut titanium, you need special tools. The best kind are high speed steel or cobalt tools because they can handle the heat titanium makes when being cut. You should also get coating for your cutting tools.

Diamond, nitride or TiN coatings will help reduce wear and tear, increase tool life and improve surface finish of the part. Finally, use variable helix tools for lathe applications to reduce chatter and vibration. This will help you achieve better results with titanium.

How do you know when titanium is done machining?

Once the cutting tool has reached the right depth and the part looks done, it is time to stop. Pay close attention to your workpiece. If you keep going, it will be damaged.

If you hear any strange noises or feel vibration while machining titanium, stop right away and check the tool and part. Over-machining titanium can cause damage to the tool and part.

How do you clean titanium after machining?

Once the job is done, use a brush to remove any leftover debris. You can also use a vacuum cleaner or compressed air if needed.

To get rid of residue, you can wipe with an oil-soaked rag or immerse in solvent and then rinse with water. Finally, make sure to use appropriate safety equipment when machining titanium.

Why is machining titanium so hard?

Titanium is a strong metal that is difficult to cut. It creates a lot of heat and vibration, which can ruin the cutting tools and the thing being cut. It is also hard to get precise results when cutting titanium because it is so strong and hard. You need special machines and tools to be able to cut titanium correctly.

Which machines are best for machining titanium?

CNC machines are good for machining titanium because they help you to be more accurate and work faster. But they need more power than manual machines, so you have to make sure your setup is strong enough before beginning any project.

When you are machining titanium, also make sure to wear safety equipment like a mask and gloves.

When should you not machine titanium?

You should avoid machining titanium when it is too hot or cold. It can be dangerous because the metal may expand and warp, causing injuries to people nearby.

You should also avoid machining titanium that has been exposed to water, as this could cause stress fractures and weaken the metal. Finally, make sure you use the right cutting tools and speed to avoid damaging the part.

Does machining titanium create any special safety concerns?

When you work with titanium, it is important to stay safe. You should wear a mask and gloves so that you do not breathe in the tiny pieces of metal created when machining titanium.

The dust from titanium can be poisonous and it can also make your skin itch if it touches you. To stay safe, always work in an area with good ventilation and keep the area around you clean. Additionally, use the right cutting tools for titanium at the correct speed to minimise risk.

Do machining speeds vary for titanium?

The speed that you machine titanium will depend on the type of tool and material being cut. Generally, it is better to use a slower speed when machining harder materials like titanium.

This can decrease wear and tear on cutting tools as well as reduce heat buildup which can cause warping or other issues with the part. Also, when machining titanium it is important to vary the speeds to ensure you get the best results.

Does machining titanium require special tools?

When you want to cut titanium, you need to use special tools. This is because regular steel cutting tools can’t handle the hardness of titanium very well and they will break quickly.

It’s better to use solid carbide or high speed steel (HSS) tools that have diamond or nitride coatings. Also, be careful about how fast you’re going. If you go too slow, there might be too much heat buildup. If you go too fast, the tool will wear out more quickly.

What are some tips for successful machining of titanium?

To get the best results when machining titanium, it is important to follow these tips:

- Use the right cutting tools: Use solid carbide or HSS tools with diamond or nitride coatings to make sure your tools can handle titanium’s hardness.

- Choose the right speed: Don’t go too fast, as this will cause your tool to wear out quickly. But don’t go too slow either; otherwise, there might be too much heat buildup.

- Use the right lubrication: Use coolant or lubricating oils to keep your cutting tools from overheating and to reduce wear.

- Ventilate properly: Make sure you have good ventilation in your workspace, and if possible, use a fume hood to prevent titanium dust from entering the air.

- Wear the right safety gear: Use a mask and gloves to protect yourself from titanium dust.

- Keep your area clean: Make sure you collect all of the titanium dust and dispose of it properly.

What are some common challenges when machining titanium?

Some of the most common challenges when machining titanium include:

- Too much heat buildup: If your cutting tool is going too slow or you don’t use a coolant or lubricating oil, there can be excessive heat buildup and warping of the part.

- Tool wear: Cutting tools can wear out quickly when machining titanium, so be sure to use the right tool for the job.

- Titanium dust: Titanium dust is very fine and difficult to collect. Make sure you have proper ventilation in your workspace and wear safety gear to protect yourself from exposure.

- Inaccurate cuts: If you don’t use the right speed and tools, it can result in inaccurate cuts and an uneven finish.

Does machining titanium require any special considerations?

When you want to cut titanium, you have to use the right tools and be careful. You need to use the proper speed and a coolant or lubricating oil. This will help reduce wear on the tool and excessive heat buildup.

Additionally, when machining titanium, always wear safety gear and make sure your workspace is well ventilated. Finally, once you’re done, dispose of all titanium dust properly.

Is machining titanium difficult?

Machining titanium is not necessarily harder than machining other materials, but it does require special tools, lubrication, and care. If done correctly with the right tools, it can be relatively easy to achieve accurate results with a good finish.

However, if done improperly, it can cause excessive wear on the cutting tool and heat buildup. For best results, use the right tools, lubricants and speed, and wear safety gear to protect yourself from titanium dust.

Can titanium be machined with CNC equipment?

Titanium can be machined with Computer Numerical Control equipment. You need to use the right tools and speeds for accurate results.

Make sure the workspace is well ventilated so you do not breathe in titanium dust. With the right setup, you can machine titanium without any problems.

Can titanium be machined by hand?

Yes, titanium can be machined by hand. However, since it is a hard material, you need to use the right cutting tools and lubricants to get accurate results without wearing out your tools quickly.

Additionally, wear safety gear and make sure the workspace is well ventilated to avoid exposure to titanium dust. With the proper setup and care, titanium can be machined by hand.

How long does it take to machine titanium?

The time it takes to machine titanium depends on how hard the task is and what tools you are using. Usually, it takes longer than other materials because titanium is harder and special tools are needed. But with the right setup, you can finish machining tasks in a reasonable amount of time.

What tools are needed to machine titanium?

The tools required to machine titanium depend on the task at hand. Generally, you will need a high-speed drill bit or end mill, carbide cutters, and a lubricant or coolant.

Additionally, it is important to use proper safety gear when machining titanium, such as a mask and gloves to protect yourself from exposure to titanium dust.

How often should the tools be changed when machining titanium?

The frequency at which the tools should be changed when machining titanium depends on how hard the task is and what type of tool is being used.

As a general rule, it is best to change out the tools often to avoid excessive wear and heat buildup. Additionally, make sure you dispose of all titanium dust properly.

Should titanium be annealed after machining?

Yes, you should heat-treat titanium after machining it. This will help to relieve stresses caused by the machining process and make the part last longer.

It will also make the surface finish of the part better and make it more durable. Make sure you follow any special instructions from the manufacturer when heat-treating titanium.

Which lubricants should be used for machining titanium?

When machining titanium, it is important to use a lubricant or coolant. This will help reduce wear on the tool and excessive heat buildup. Some suitable options include oil-based cutting fluids, water-soluble emulsions and soluble oils.

Can titanium be plasma cut?

Yes, titanium can be plasma cut. However, you will need to use a specialised type of cutting fluid and make sure the workspace is well ventilated during the process.

Additionally, wear safety gear to protect yourself from titanium dust exposure. With the right setup, you can accurately plasma cut titanium without any issues.

Useful Video: Mastering the Art of Machining Titanium

Conclusion

Despite the difficulties in machining titanium, there are ways to overcome them. By using the correct tools and techniques, as well as understanding the different properties of titanium, you can machine this difficult material with success.

With its superior strength and corrosion resistance, titanium is an excellent choice for many applications. Have you had success machining titanium? Share your tips in the comments below.

References:

- https://www.harveyperformance.com/in-the-loupe/titanium-machining/

- https://makeitfrommetal.com/how-to-machine-titanium-like-a-pro/