Cleaning your engine is a vital part of maintaining your car. If dirt and dust build up on your engine parts, it can cause damage and affect the performance of your vehicle. In this guide, we will teach you how to clean Aluminum Engine Parts using safe and effective methods. We’ll also show you how to protect them from corrosion in the future!

What is Aluminum?

Aluminum is a soft, lightweight metal that is used in a variety of industries. It is also one of the most abundant elements on earth, making up around eight percent of the earth’s crust.

It is durable, corrosion-resistant, and has excellent thermal conductivity. [1]

Cleaning Aluminum Engine Parts is important to keep your car running smoothly. Over time, dirt and grime can build up on the surface of Aluminum Parts and cause them to become less effective. If left uncleaned, Aluminum Engine Parts can eventually fail completely. Fortunately, cleaning Aluminum Engine Parts is relatively simple and only requires a few household items!

How to clean Aluminum Engine Parts Step By Step

Step 1: The Primary Methods

There are two primary methods for cleaning Aluminum Engine Parts: manual cleaning and using a pressure washer.

This involves scrubbing the dirt and grime off of the surface of the aluminum with a brush or cloth.For more tough stains, you may need to use a pressure washer. Pressure washing is an effective way to remove heavy buildups of dirt and grime. However, it is important to be careful when using a pressure washer on aluminum engine parts. Too much pressure can damage the metal or cause it to warp.

Step 2: If the Dirt is Denser

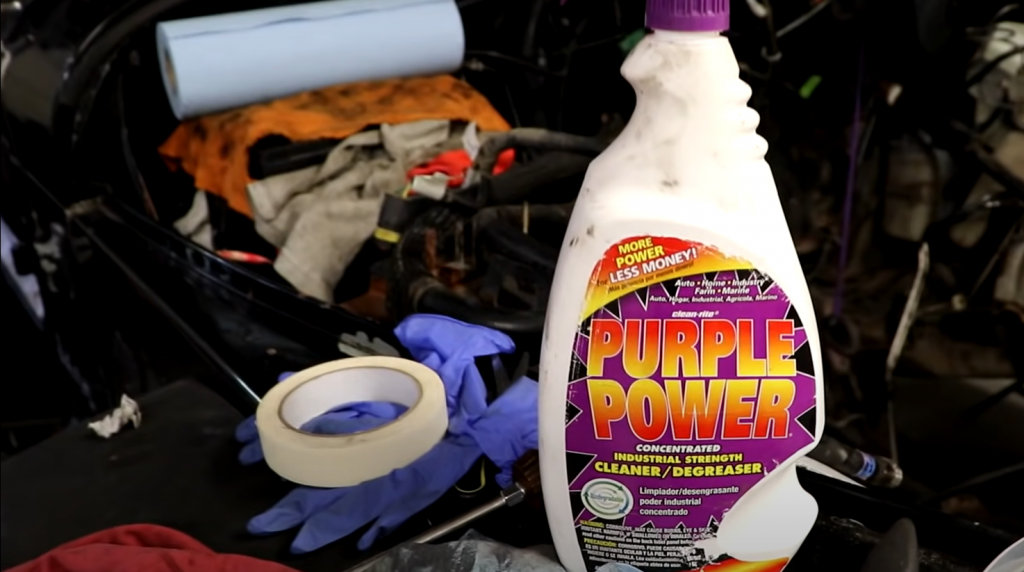

If the dirt on your Aluminum Engine Parts is dense, you may need to pre-treat it with a degreaser. Degreasers are chemicals that break down oil and grease. This will make the dirt easier to remove and will prevent it from causing further damage to the aluminum.

After you have degreased the surface of your aluminum engine parts, you can begin cleaning them. If you are using a pressure washer, start with the lowest setting and work your way up if necessary. Hold the nozzle about six inches away from the surface of the metal and use even strokes to avoid damaging the aluminum.

Step 3: Using a Wire Brush

The next step is to use a wire brush. This will help to remove any stubborn dirt and grime that may be stuck on the surface of your Aluminum Engine Parts. Be sure to scrub in a circular motion and avoid using too much pressure, as this could damage the metal. [2]

After you have scrubbed the surface of your Aluminum Engine Parts with a wire brush, it is time to move on to the next step: sanding. Sanding will help to smooth out any rough edges and give your engine parts a nice, polished finish. Be sure to use fine-grit sandpaper so that you do not damage the metal.

Once you have sanded your engine parts, it is time for the polishing. This will help to protect your engine parts from corrosion and give them a nice, shiny finish. Be sure to use a high-quality polish and apply it in a thin, even layer. Allow the polish to dry completely before moving on to the next step.

How to remove oxidation from Aluminum Engine Parts?

Step 1: Cleaning Aluminum Surface

Aluminum surfaces are delicate and require special care when cleaning. Use a soft cloth or sponge to avoid scratching the surface.

Step 2: Cleaning Using Natural Cleaners

Natural cleaners are a safe and effective way to clean aluminum engine parts.

Apply the mixture to the aluminum surface using a clean cloth. Rub in a circular motion until the oxidation is removed. Rinse the area with clean water and dry thoroughly.You can also use a mild soap and water solution. Apply the soap to a clean cloth and rub in a circular motion. Clean the area with water and dry it off completely.

Another option is to use lemon juice. Simply apply lemon juice to a clean cloth and rub it onto the aluminum surface in a circular motion. Rinse the area with clean water and dry thoroughly. [3]

Whichever method you choose, be sure to rinse the area well and dry it completely to avoid corrosion.

Step 3: Using the Oxidation Removal Product

There are many oxidation removal products available on the market.

Choose a product that is safe for aluminum and follow the instructions on the packaging.

Apply the solution to a clean cloth and rub onto the aluminum surface in a circular motion. Rinse the area with clean water and dry thoroughly. [4]

This will help to prevent future oxidation and keep your engine parts looking new.

Pay attention to any areas that are particularly susceptible to corrosion, such as the engine block or exhaust system. These areas should be cleaned more often to prevent build-up of corrosion-causing materials.

FAQ

What is the best cleaner for Aluminum?

There are a few different ways to clean aluminum engine parts. You can use a commercial cleaner, or you can make your own cleaning solution at home.

To make your own cleaning solution, mix equal parts of water and vinegar in a bowl. Then, add a tablespoon of baking soda and stir until the mixture is foamy. Finally, add enough cornstarch to thicken the mixture so that it clings to the surface of the aluminum.

Apply the cleaning solution to the aluminum surface with a sponge or cloth and scrub gently. Rinse with water and dry with a soft cloth. Repeat as necessary until the aluminum is clean.

If you prefer, you can also use lemon juice or cream of tartar instead of vinegar in your cleaning solution. Just be sure to rinse the aluminum well after cleaning, as these acidic ingredients can cause corrosion if they’re left on the surface.

For stubborn stains, you may need to use a commercial cleaner. Be sure to read the labels carefully and follow the instructions, as some cleaners are corrosive and can damage aluminum if used improperly.

Once you’ve cleaned the aluminum, it’s important to protect it from further damage. Apply a thin layer of wax or sealant to the surface to create a barrier against dirt, grease, and other contaminants.

How do you clean corrosion off Aluminum?

There are two ways to clean corrosion off of aluminum: using a chemical process or an electrolytic process. The chemical process uses a caustic solution, such as lye or vinegar, to eat away at the corrosion. The electrolytic process involves passing an electric current through the metal to break down the corrosion.

If you’re working with small parts, you can clean them with a wire brush or sandpaper. For larger parts, you’ll need to use a power washer or sandblaster. Whichever method you choose, make sure you protect yourself from the fumes and wear gloves to avoid getting any chemicals on your skin.

Once you’ve removed the corrosion, it’s important to protect the metal from further damage. This can be done by painting it with corrosion-resistant paint or coating it with oil. You should also avoid exposing the metal to moisture and salt, which can cause corrosion.

What Can I Spray on Aluminum to Clean It?

You may clean the aluminum with a natural cleanser. To make a natural cleaner, combine 2 teaspoons of vinegar with every 4 liters (liter) of water. Now let your solution simmer for 10 to 16 minutes. When your solution is ready, plunge the aluminum piece into it and clean it. [5]

You can also use a product that is specifically designed for cleaning aluminum. When choosing a product to clean your engine parts, it is important to select one that will be gentle on the finish of your engine parts while still being effective at removing dirt and grime. Many people recommend using a product called Aluminum Brightener. This product is designed specifically for cleaning aluminum and will not damage the finish on your engine parts.

Will baking soda clean Aluminum?

Yes, baking soda is an effective way to clean aluminum. You can make a paste with baking soda and water, and then use it to scrub away dirt and grime. Rinse the area afterwards with clean water to remove any residue.

Another option is to mix equal parts of baking soda and vinegar together, and then use this mixture to scrub the aluminum surface. After you have used this solution, rinse the area with clean water.

What should you not clean Aluminum with?

You should avoid using harsh chemicals or abrasives when cleaning aluminum engine parts. Harsh chemicals can damage the finish on aluminum and cause it to dull over time. Abrasives can also scratch the surface of aluminum, making it more difficult to clean in the future. Instead, opt for gentle cleaners that are designed specifically for use on aluminum.

Another cleaner to avoid is bleach. Bleach is a strong chemical that can damage the surface of aluminum. If you must use bleach to clean your Engine Parts, be sure to rinse it off immediately with water.

Can You Use Degreaser on Aluminum?

Degreasers are not just for engines; in fact, they can be used on a variety of surfaces. However, you should avoid using a degreaser on aluminum. Degreaser can cause aluminum to pit and corrode. If you must use a degreaser on aluminum, make sure to rinse it off immediately and dry the surface thoroughly.

Useful Video: Super Clean Aluminum Engine Parts

Conclusion

Cleaning aluminum engine parts is not difficult, but it does require some care and attention. The most important thing is to use the right products and to take your time. With a little bit of effort, you can make your engine look new again. In this guide, we have shown you how to clean Aluminum Engine Parts using safe and effective methods. We have also provided tips on how to protect them from corrosion in the future.

Now that you know how to clean aluminum engine parts, it is time to put your knowledge into practice! Be sure to follow these steps carefully and you will have shiny, polished engine parts in no time.

Thanks for reading! We hope this guide was helpful.

References:

- https://rxmechanic.com/clean-aluminum-engine-parts-and-oxidation/

- https://royalmechanic.com/how-to-clean-aluminum-engine-parts/

- https://www.mcnallyinstitute.com/what-to-use-to-clean-aluminum-engine-parts/#2

- https://vehiclefreak.com/how-to-clean-oxidized-aluminum-engine-parts-complete-guide/

- https://mechanicalboost.com/how-to-clean-oxidized-aluminum-engine-parts/#What_Can_I_Spray_on_Aluminum_to_Clean_It