It happens that you are not satisfied with the quality of the metal tool you have bought. If you need to increase the hardness or plasticity of the material you can perform such a technological operation as annealing. After detailed studying and preparation, it is possible even at home.

In some cases, we perform the heat treatment of steel not only to increase the hardness but also to reduce it. When the hardness parameter is low the cutting surface of the tool can be jammed in the process of work. On the contrary, if this parameter is too high the metal crumbles due to mechanical stress.

To solve this problem read the article to find out what tools you need to perform annealing of steel at home without professional equipment. Remember that not all types of steel are annealed, for example mild steel. However, you can easily increase the hardness parameter of carbon and steel alloys on your own.

Annealing methods

The annealing process is divided into two stages. This first is a heat treatment of metal and the second is cooling. Different metals and steel categories have different structures and that’s why the heat treatment must be performed accordingly.

Two main characteristics of metal can be improved in the process of heat treatment. They are the hardness and plasticity. Follow all the recommendations to perform the process correctly and to avoid mistakes.

When black and blue spots appear on the surface of the metal it means something goes wrong. This way you can spoil the tool. The bright red color of the metal surface will tell you that everything is fine.

The process of heat treatment is not as simple as it looks from first sight. Always pay attention to the structure of the material and its characteristics. Without preliminary analysis and preparation, you are likely to deform the metal piece.

To avoid undesirable results and the deformation of metal which happens very often with mild steel check the category of metal in advance. You can find it on the Internet or from the provider. If you don’t know the information, heat treatment is not recommended in this case.

To heat treat the metal you have to reach very high temperatures. Several heat sources are available for home use. You can choose a special heat treating oven, a torch, or an open fire, but the choice will always depend on the temperature, which must be reached for annealing the definite category of steel.

Note that the heat of the open fire can be not enough in some cases. Always check the melting point and the tempering temperatures of the material before starting the procedure of heat treatment to receive the best results. In the opposite case, you risk deforming the tool.

A heat treating oven

A special heat treating oven is the best for full and reliable annealing. If the oven is computerized you set the required program and leave it. Return after a definite time to get the part, when it’s already been cooled down properly.

It is comfortable in use and suitable for pieces of different thicknesses. Of course, one doesn’t usually have such an oven at home and you have to know the grade of steel to use it. An average temperature from 1450 to 1650 F can be set but to anneal the steel fully you have to know it exactly.

As you reached the desired level of temperature let the piece soak – keep the metal for some time at this temperature. For every inch of diameter let 1 hour to soak. Use this golden rule when the metal piece is not even, always consider the thicker end as the indicator. Turn off the equipment and don’t open the door for several hours to cool the piece slowly.

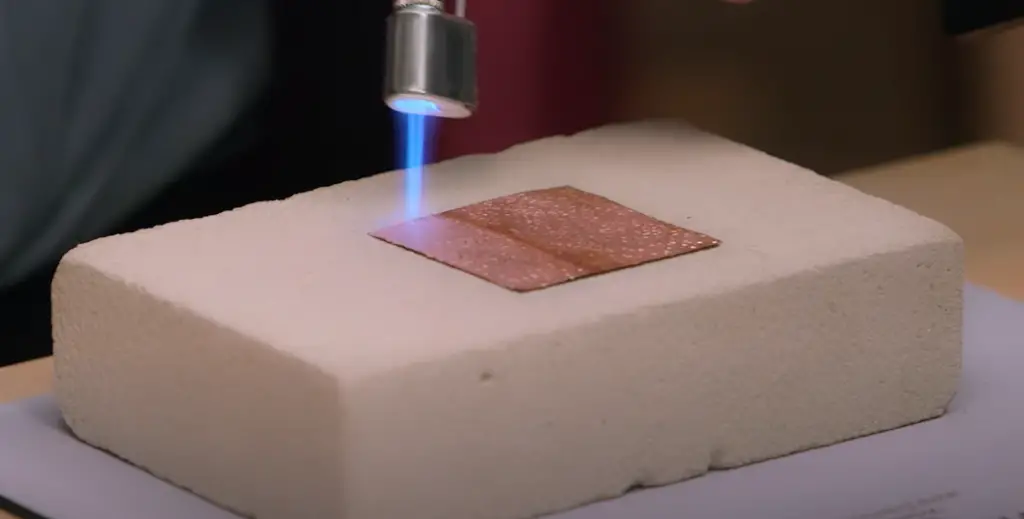

A torch

Annealing with a torch is the easiest and the fastest method, especially for small parts. It’s a common tool and that’s why it’s more accessible to most craftsmen. The grade of steel is not important in this method, as the color of the metal shows the right temperature. For annealing reach orange-red, for heat-treating cherry-red is enough.

Special skills are needed to use a torch and it’s difficult to cope with different thicknesses. This tool takes second place after the oven, which is more reliable and consistent. Keep away the flame from a thin section not to melt it, instead heat the thicker end, let the heat spread through the whole piece.

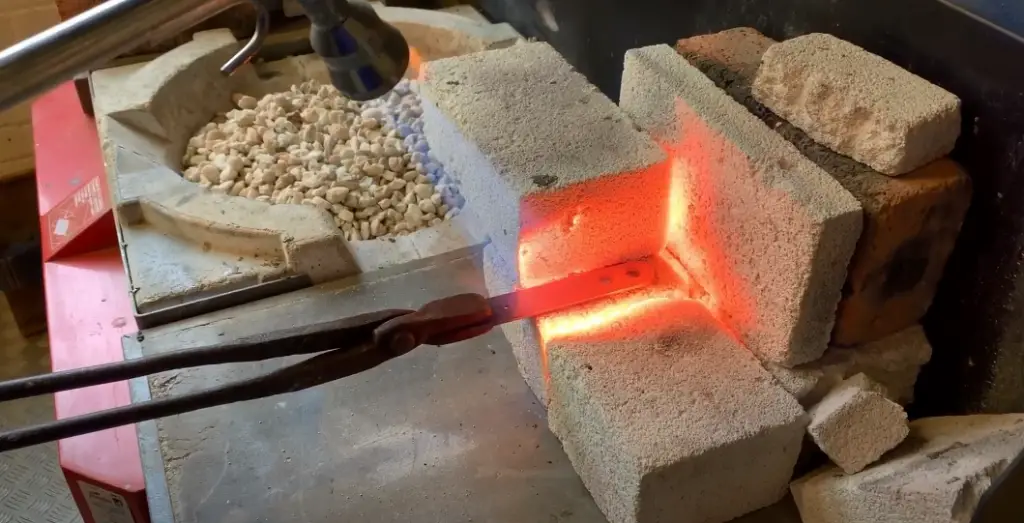

An open fire

An open fire can be used as a heat source. For annealing, a fire with lots of hot coals is required. Prepare blacksmith tongs to take out the heated steel from the fire. Consider what cooling method is suitable for you and prepare everything beforehand.

When you finish all preparations and have enough hot coals in the fire you can start the heat treatment process and insert the steel piece inside. You can evaluate the temperature of coals by their color. They have to be bright red with a white surface.

Monitor the color of the flame as well. Crimson is perfect, the white color indicates that the temperature is too high and you risk to overheat and even burn the steel. Keep a close eye on the color of the heated steel. Never allow black and blue spots on the surface of the piece, which indicates that the metal is already too soft and plastic.

Pay special attention to elongated tools for example drills or nails. Descend them into the coolant vertically with the end of a bigger diameter. Never put them sideways, as the thinner part will deform and flatten because of the high temperature and fast contact with your insulator.

3 stages of annealing

There are 3 stages of annealing, which change with the increase in temperature. The first is recovery when the material softens and is relieved from inner stresses at quite low temperatures. The recrystallization stage follows when new grains without strain are formed to replace the deformed ones. The final stage is grain growth, when the steel microstructure begins to coarsen.

The cooling process

When you choose a cooling mode think of the material and the results you want to achieve. If you have a need to harden only a definite part for example the cutting edges of the tool don’t temper the entire piece. Carry out the cooling pointwise as well under the cold water flow.

The technological peculiarities can require rapid, gradual or multi-stage cooling. Instant cooling mode uses a single type of coolant. Carbonaceous or alloyed steels are hardened that way. An ordinary bucket, barrel or a bathtub will suit as a container, depending on the dimensions of the metal piece you are hardening.

The method with two coolants when you have to harden the steel of other categories or when you plan not only to harden but also to temper the steel. After heating the metal piece to the required temperature cool it in a container with water. later put it in the second container with mineral or synthetic oil. Never use the oily coolant first because it will ignite from the temperature of the heated metal piece.

It is recommended to think and prepare a coolant before heat treatment. Take any container, fill it with water, but keep in mind that the metal piece must fit completely into it. If you harden consumables made of steel you can use an ordinary cut plastic bottle. For an ax or similar working tools you will need a container with a bigger volume.

Slow cooling options for annealing steel

There are lots of recommendations when water and oil are used for cooling steel. But if you want to receive reliable and safe annealing results think of the following options of slow cooling.

Dry sand

For slow cooling, you can use dry sand, which keeps the temperature of the annealed piece longer. The sand for play or construction will do but it must be pure. Never apply wet sand as it will lead to negative annealing results and can be dangerous for you.

Insulating blanket

It is very convenient for use and storage – just roll it up and return to the shelf. Several types will do the job: blankets for wood stoves, chimneys, or a roll of insulating ceramic fiber, so you can choose the most available.

Salt solution (brine)

Among typical cooling methods, there is a salty solution or brine. Compared to water, it does the job quicker. In ordinary water, the surface of a metal piece is covered with steam bubbles. The brine gives better and quicker cooling results due to reduced bubble formation. This method is mostly used in production.

Useful tips and precautions

Many working tools do not feature the high quality of steel. Sometimes it’s not possible to harden the steel in the manufacturing process or, on the contrary, this parameter can be overdosed. Everybody knows about drills. If they are not hardened enough they bend. If overhardened, they crumble.

After the heat treatment in home conditions remember some peculiarities about cooling all elongated objects. You have to place them vertically into the container with the chosen coolant. Always immerse such items into the coolant with the thicker end. If the thinner part goes first it is likely to suffer from the compression and will deform.

Before you start to work with a recently purchased tool, you can check the quality of steel at home. Take an ordinary soldering iron. Draw along the steel surface of the tool with the tip of the soldering iron to find any defects.

When the tip of your iron sticks to the steel surface it means that the metal was not hardened enough. Most likely such a tool will deform if you use it often. The opposite situation is when the iron tip glides smoothly on the surface and practically bounces off it. It means the steel is overhardened and heat treatment is required.

Small parts are sometimes close to impossible to cool slowly unless a special heat treating oven is used. There is one more option for home use. Find a bigger piece of metal or two, heat it together with the small piece which is being annealed.

For cooling in the insulator attach the bigger hot parts in close contact with the smaller one. This allows steady slow cooling for the best annealing results. The blocks keep the steel part hot for a long time. The required decrease in temperature is 70 F an hour. The cooldown continues up to 500 F.

Remember that annealing is not the same as tempering. In the first case, the material becomes soft and malleable. In the second one, internal stresses are relieved and its brittleness is reduced. Higher temperatures are used for annealing about 1500 F, whereas 500 F will be enough for tempering.

Normalizing also differs from annealing. Annealing is carried out through a slow cooling process at controlled temperatures while normalizing cooling is performed fast in the open air. The steel becomes partially hard with reduced inner stress and uniform grain structure.

FAQ

What is the process of annealing steel?

Annealing steel is a process of heating and cooling the metal to alter its physical and chemical properties without changing its shape. Heat is applied in order to increase the temperature of the metal beyond its recrystallization point, which causes new grains of a different size to form within the steel. The newly formed grains make the metal softer, more ductile, and more workable. After the steel is heated, it must then be cooled in order to complete the annealing process. The cooling procedure depends on the type of metal being annealed as different metals require different cooling rates. Generally speaking, this process involves slowly cooling the steel by gradually reducing the temperature over a period of time until it reaches room temperature. This allows for any internal stresses that were built up during heating to be released from the metal. Annealing steel also reduces hardness and increases ductility so that it can be further manipulated into certain shapes or sizes. Finally, once the annealing process has been completed, the steel is ready for use in whatever application is needed!

How do you soften hardened steel?

The most common method of softening hardened steel is through tempering. Tempering involves heating the steel to a specific temperature and then cooling it rapidly. This process increases the hardness and strength of the steel, while also making it more brittle. To soften hardened steel, you must heat it to a lower temperature than its original hardening temperature and cool it very slowly. You can do this in an oven, or with a torch if necessary. Be sure to watch the steel closely as you’re tempering it, since too much heat can damage it beyond repair! Once cooled properly, your hardened steel should be softer and less brittle.

What temperature does steel anneal at?

Steel typically anneals anywhere from 800 to 1550°F (427 to 843°C). This range of temperature will depend on the type of steel being annealed as well as its intended application and desired properties. For instance, a low-carbon steel may be annealed at around 950°F (510°C), while a higher-carbon steel may need to reach temperatures closer to 1500°F (815°C). Annealing is also done at different times depending on the type of steel and its intended use. Some steels require short annealing times, while others can be left in the oven for hours or even days. Generally, most types of steel should be heated slowly until they reach their desired temperature, then allowed to cool slowly as well. This process helps the steel retain its hardness and strength while ensuring its structure is even throughout. It’s important to remember that too much heat can cause stress or warping in certain steels, so it’s best to consult with a professional before attempting any annealing yourself.

What are the 3 stages of annealing?

The three stages of annealing are recovery, recrystallization, and grain growth.

Recovery is the first stage, where materials that have been deformed due to plastic or cold working are brought back to their original state. During this process, heat is used to restore the material’s physical properties and microstructure.

The second stage of annealing is recrystallization, which occurs when atoms re-arrange themselves into new crystals. This helps change the structure of a material, making it more ductile and malleable.

Finally, in the third stage of annealing known as grain growth, larger grains will form as grains with lower energy states grow at the expense of smaller ones. This helps reduce any internal stresses caused by uneven grain sizes.

Overall, annealing is a heat treatment process that helps improve the mechanical and electrical properties of materials, making them stronger and more durable.

How long do you anneal steel?

It depends on the type of steel and the desired outcome. Generally, steels are annealed anywhere between 20 minutes to a few hours at temperatures ranging from 800°C to 900°C. A typical process would involve heating up steel until it reaches its austenitization temperature, then letting it cool down slowly in a controlled environment to reach its equilibrium state. If you’re unsure about how long or what temperature to anneal your steel at, it’s best to consult with a professional who can provide more specific guidance.

How long does annealing last?

The duration of annealing depends on the material being annealed, as well as the desired outcome. Generally, annealing can take anywhere from a few minutes to several days. The temperature and length of time will depend on the metal being worked with, so it’s important to research and understand the properties of each specific metal before beginning your annealing process. Additionally, you can always consult with a professional to ensure that you’re using the right techniques for your project.

Is annealing the same as tempering?

No, annealing and tempering are two different processes. Annealing is a heat treatment process that alters the physical and sometimes chemical properties of a material to make it more ductile and reduce its hardness, making it easier to work with. Tempering, on the other hand, is another heat-treatment process used to strengthen already hardened materials by adjusting their microstructure. It’s usually done after annealing or quenching in order to further increase the durability of the material. Both processes have valuable uses in metalworking and engineering applications.

Does annealing steel make it softer?

Yes, annealing steel makes it softer. This is done by heating the steel to a certain temperature and then cooling it slowly over time. This causes the metal’s grain structure to become more uniform, which reduces its hardness and makes it easier to work with. Annealing can also help to reduce the risk of cracking during machining or forming processes. It’s important to note that annealing does not make steel weaker – simply less brittle and therefore more malleable for use in specific applications.

The exact temperatures used for annealing depend on the type of steel being used, so it’s important to consult a professional for advice when deciding what temperature is best for any given project. Additionally, there are different types of annealing processes (full, process, and subcritical) that can be used depending on the desired outcome.

Does annealing make steel stronger?

Yes, annealing can make steel stronger! The process of heating and slowly cooling steel makes it more malleable and less brittle, resulting in a stronger final product that’s better able to withstand stress. This is why annealing is so important for many industries that rely on strong steel products. It’s also why the heat-treating process has been used for centuries – because when done properly, it strengthens the metal and improves its overall quality. So if you’re looking to make your steel products as strong as possible, definitely consider adding an annealing step in your production process!

Does annealing weaken steel?

Yes, annealing can weaken steel. The process makes the steel more ductile and malleable, which can reduce its strength. It also reduces internal stresses in the material so it won’t crack or break as easily. The downside is that the resulting steel may not be as strong as before, but this isn’t necessarily bad–sometimes you need softer metals for specific applications. So if your project demands softer steel, annealing is definitely worth considering!

But one thing to bear in mind is that different types of steels react differently when subjected to annealing, and some are more prone to becoming weakened than others.

Finally, keep in mind that annealing isn’t always necessary – in some cases, traditional heat-treating processes can achieve the same results without weakening the steel. So it’s important to understand all your options before deciding on the best way to go about treating your metal.

How do you remove hardness from metal?

Removing hardness from metal is done through a process called annealing. This process requires heating the metal up to a certain temperature and then allowing it to cool very slowly in order to reduce its hardness. In some cases, other materials may be added to the metal during this process in order to help soften it further. The exact method of annealing used will depend on the type of metal being worked with and what kind of properties are needed for the finished product. To ensure that the correct procedure is followed, consult your local metalsmith or metallurgist before beginning any hardening or softening processes with metals.

Does steel need to be annealed?

Yes, steel needs to be annealed in order to reduce its hardness and make it more malleable. This process involves heating the steel up beyond its critical point, holding it at that temperature for a set amount of time, then allowing it to cool slowly back down. The result is a softer piece of metal that can be easily forged or shaped into whatever desired shape. Annealing also helps prevent micro-fracturing which can lead to breakage over time. So if you’re working with steel, be sure to give it the proper treatment by annealing!

Conclusion

Metal heat treatment can improve the quality of tools or consumables. When annealing steel at home, it is important to remember the basic recommendations not to deform the material and get desirable results.