Stainless steel and aluminum are two metal choices that come up a lot in the kitchen. What’s the difference between stainless steel and aluminum? Is one better than the other? Stainless Steel vs Aluminum: Ultimate Guide will tell you everything you need to know about these metals, including what they’re made of, how they differ from each other, and which is best for your needs.

General Differences between Aluminum and Stainless Steel

Stainless steel is more expensive than aluminum.

Aluminum has a lower melting point and can be melted in an oven at around 1200 degrees Fahrenheit, while stainless steel melts between 1800 and 2500 degrees Fahrenheit. Although you’ll generally need to use a torch or other direct flame for heating metal alloys like this (which can be dangerous).

Stainless steel is less dense than aluminum. This means it will float on water while aluminum will sink.

Strength to weight ratio

Both steel and aluminum are incredibly strong. However, the strength to weight ratio of aluminum is much stronger than that of stainless steel. The reason behind this? Aluminum has a lower density compared to steel which means it’s lighter in weight despite its impressive strength. Aluminum is also more malleable than steel, which means it can be bent thinner without breaking.

Steel has a strength to weight ratio that’s about five times greater than aluminum. However, stainless steels are very heavy due to their density, making them harder to transport while using less material in the process of production compared with aluminum.

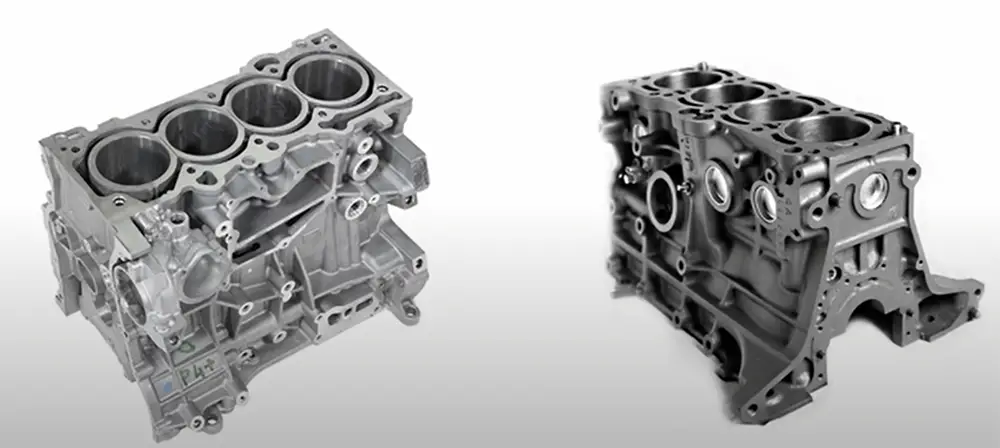

The combination of weight and strength makes aluminum a better choice for products that need to be light but durable. Aircrafts, bicycles, and cars are all commonly made with aluminum because it provides the perfect balance of these two characteristics.

Corrosion

Stainless steel is more resistant to corrosion than aluminum. Aluminum can corrode by reacting with water or other elements present in the atmosphere. This reaction results in an oxide film that will appear on its surface, which might eventually lead to pitting and erosion of the metal’s material properties if it continues for a long time without being treated. Stainless steel, on the other hand, forms a passive oxide layer that protects it from further corrosion and makes it more durable in different environments.

This does not mean that stainless steel is immune to corrosion. In fact, all metals corrode to some degree if left untreated. The key difference between stainless steel and aluminum is that aluminum will corrode faster than stainless steel, which is more durable.

Thermal Conductivity

Thermal conductivity is the ability of a material to transmit heat. Stainless steel has a higher thermal conductivity than aluminum, meaning that it transmits heat better. This makes stainless steel a better choice for applications where heat needs to be transferred quickly, such as in cookware or engine parts.

However, aluminum is still a good thermal conductor when it comes to non-extreme applications. Aluminum is often the material of choice for things like household appliances, aluminum foil and soda cans.

Cost

Aluminum is typically cheaper than stainless steel. In fact, aluminum pans are often the first ones that people buy when they’re just starting out with cooking and don’t have a lot of money to spend on them. Although initially less expensive, you would need to replace those fairly quickly because their lifespan isn’t as long as a stainless steel pan.

Workability

One of the major differences between stainless steel and aluminum is workability. Stainless steel is much more difficult to work with than aluminum. It is tougher, harder, and has a higher melting point. This means that it is more difficult to form, cut, weld, and drill. Aluminum is softer and easier to work with than stainless steel.

Welding

There are many different types of welding processes that produce different results. Some examples include oxy-fuel, submerged arc welding, gas metal arc welding (GMAW), flux cored wire, and more. The differences between the various methods is significant enough to where you should take some time to learn about them if you own a business or do any welding yourself.

Stainless steel and aluminum are two of the most common metals that are welded. They both have their own benefits and drawbacks, so it’s important to know which one is best for your specific welding project. In this article, we will take a look at the differences between stainless steel and aluminum welding.

You might be interested in related articles:

Thermal properties

Aluminum is a much better heat conductor than stainless steel. This means that if you’re cooking something on the stove, aluminum will get hotter faster and more evenly distribute heat to cook it quickly. You can also use an aluminum pot or pan for boiling water in half the time as compared with a stainless steel one. However, this property is the very reason why aluminum cookware should never be used for acidic foods like tomato sauce, vinegar or citrus juices.

For example, when you cook an acidic food in a stainless steel pot or pan it’s not directly exposed to aluminum so there are no issues with your meal. However aluminum can leach into these types of dishes and cause food to turn out metallic tasting.

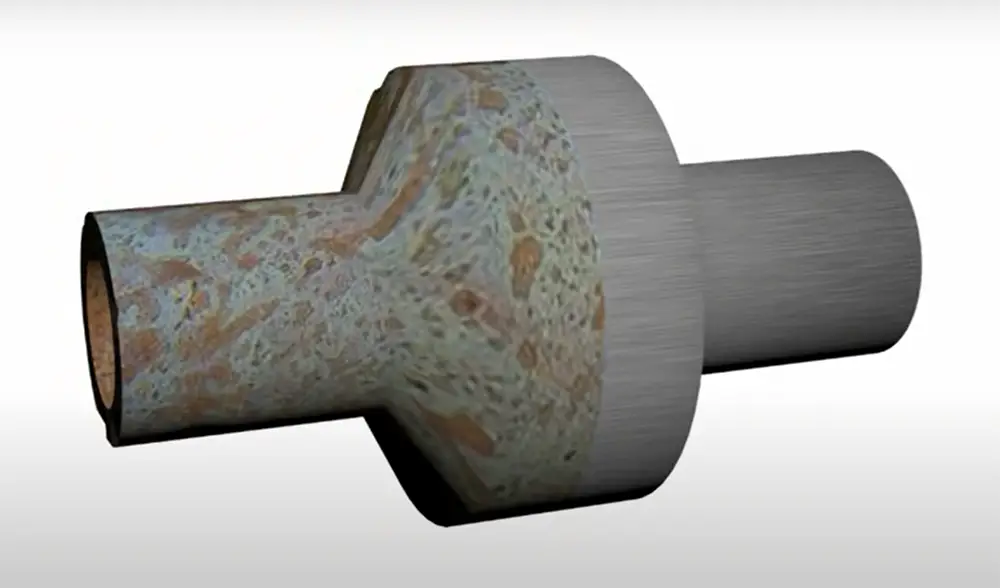

What about stainless steel? It’s not as good of a heat conductor, so stainless steel pots and pans are often made with layers including copper or aluminum sandwiched in between the steel for better heating properties. You can even buy cookware that is entirely made from one type of metal. For example, tri-ply stainless steel cookware has a layer of aluminum sandwiched in between two layers of stainless steel, so it performs almost as well as an aluminum pot or pan, without the risk of leaching.

Electrical Conductivity

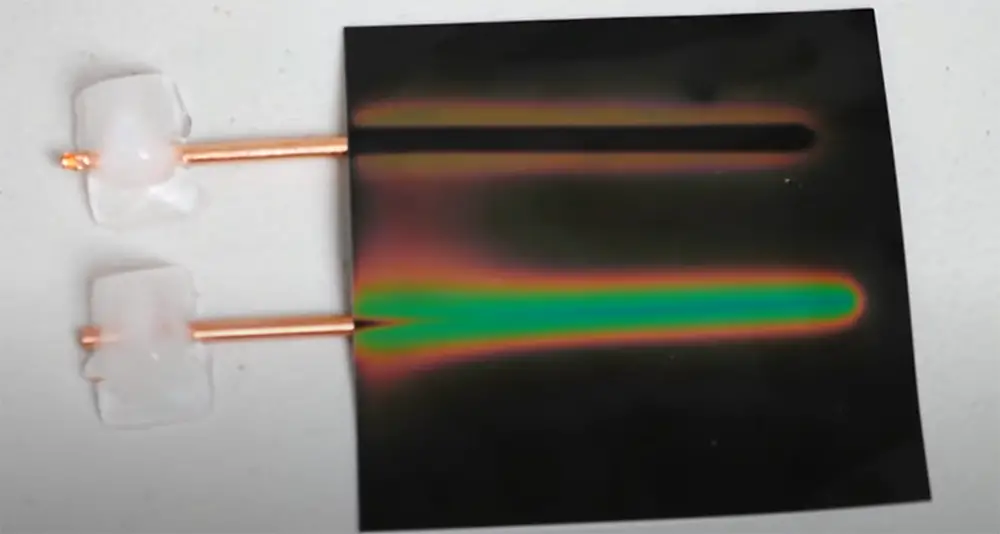

Both stainless steel and aluminum conduct electricity, but the rate at which it occurs varies between the metals. Aluminum is a better electrical conductor than stainless steel because of its smaller grain size and higher amounts of trace minerals contained in it. Stainless steels’ resistance to corrosion decreases its electric conduction while aluminum’s high conductivity makes for excellent wiring material.

Strength

Stainless steel is much more durable than aluminum. This means it can stand up to a lot of wear and tear, like repeated use or extreme conditions such as heat. Aluminum doesn’t hold up well in hot temperatures; the metal will deform when exposed to high levels of heat, which makes it unsuitable for cooking with.

Effect on Foods

Aluminum is less dense than most metals, which means that your food will heat up more quickly in it. This can be dangerous if you’re using aluminum pots and pans for cooking the dishes because metal conducts heat faster. You might end up burning yourself or overcooking things like meat or seafood! While stainless steel does conduct heat well, it doesn’t transfer it as quickly as aluminum so your food will be in contact with the heat source for a little longer, giving you more time to regulate the temperature.

Aluminum is also known to react with acidic foods and release toxins into the dish. This can cause discoloration or an off-taste in whatever you’re cooking.

Stainless steel, on the other hand, is non-reactive with acidic foods. This means that you can cook your favorite tomato sauce or lemon chicken in stainless steel pots and pans without worrying about toxins! Because of this property ,stainless steel is also considered to be safer for use by people allergic to certain metals like aluminum.

In addition to the difference in reactivity, stainless steel is also less likely to corrode or tarnish over time. Aluminum can start to show signs of wear and tear after prolonged use, but a good quality stainless steel pot or pan will last you for years without any problems!

The Key Test for Comparing Stainless Steel and Aluminum

The two metals are commonly compared, but what is the key test for distinguishing them? The difference between stainless steel and aluminum boils down to one factor: corrosion. Stainless steel is less prone to corroding in the presence of certain elements, while aluminum will corrode more quickly. This susceptibility to corrosion is determined by several factors, from the alloy to what environment it is exposed to. For example, an aluminum stove top will corrode more quickly if placed in a kitchen that has salt or chlorine-rich water sources nearby.

FAQs

Which is harder stainless steel or aluminum?

Stainless steel is harder than aluminum. It has a higher density and a lower coefficient of thermal expansion. This means that it is less likely to deform when subjected to heat or pressure.

Will stainless steel rust?

Stainless steel does not rust and corrode in the same way as other metals, such as iron or aluminum. Rust is common when metal oxidizes after exposure to water and air over time.

Why is stainless steel better than aluminum?

Stainless steel is an incredibly durable material that can withstand a lot of wear and tear without corroding or rusting. Compared to aluminum, stainless steel won’t dent or scratch as easily, making it a better choice for surfaces that come in contact with hard objects. Additionally, stainless steel doesn’t react with acidic substances like fruits and vegetables, so it’s the preferred material for food storage containers. Finally, stainless steel is heat resistant and doesn’t react to changes in temperature or humid environments like aluminum does. All of these factors make stainless steel a better choice than aluminum for many applications.

Is stainless steel and aluminum the same?

No, stainless steel and aluminum are not the same. stainless steel is an alloy composed of iron, chromium, and other elements like nickel and molybdenum. It’s designed to resist corrosion and rusting. Al, on the other hand, is a soft metal that’s lightweight yet strong. While it can be treated with chemicals or coatings to make it more resistant to corrosion, oxygen will still react with its surface if left untreated. Each material also has unique properties that make it suitable for different applications — stainless steel is often used in construction due to its strength and durability while aluminum is popular in automotive manufacturing because of its lightness. Ultimately, their differences should be taken into account when deciding which one to use for a particular project.

How strong is aluminum vs stainless steel?

These alloys are both very strong materials. stainless steel is often more expensive than aluminum and has a higher tensile strength, but aluminum has better resistance to corrosion. If you’re looking for a metal that can withstand a lot of wear and tear, stainless steel would be the better choice, however, if you need a material that won’t corrode or rust easily then aluminum is your best bet. Ultimately, it depends on what you need the metal for as both metals have advantages and disadvantages. You should always evaluate which metal will work best for your specific needs before making your purchase.

What rusts faster aluminum or stainless steel?

Aluminum does not rust, but depending on the environment it may corrode. In general, stainless steel is more resistant to corrosion and rusting than Al. Stainless steel is made up of iron with chromium added, which helps protect the metal from oxidation. The chromium creates a layer on the surface that prevents oxygen and water from reacting with the iron in the alloy beneath. This protective layer can be damaged if exposed to certain chemicals or left out in saltwater for too long, however, so it’s not completely immune to rusting or corrosion. Ultimately, both materials are great choices when considering durability and longevity, but stainless steel will likely last longer than aluminum due to its greater resistance to corrosion and rust.

Which is safer: stainless steel or aluminum?

The answer to this question largely depends on the specific application you are using. Generally speaking, both alloys can be considered safe for most applications, but there are some differences worth noting.

Stainless steel is strong, durable, and resistant to corrosion and rusting. It’s non-toxic and mostly impervious to heat damage or cold temperatures. However, it is heavier than aluminum and has a higher cost associated with it due to its strength.

Aluminum is lightweight and relatively inexpensive compared to stainless steel – but it doesn’t offer the same level of durability. aluminum is softer than stainless steel, making it more prone to denting and scratching if not properly handled. Additionally, aluminum may react with certain food-related chemicals, which can cause corrosion.

Overall, both stainless steel and aluminum are safe for most applications. However, if you need a material that is more resistant to corrosion or wear and tear, then stainless steel may be the better option. Be sure to weigh the pros and cons of each material before making your decision.

Which is more expensive, aluminum or stainless steel?

The answer is that it depends. Generally speaking, stainless steel is more expensive than aluminum because it has better properties — like being more resistant to corrosion and rusting — but there are also grades of each metal with different prices. For example, 316 grade stainless steel is usually more expensive than 6061 grade aluminum. It really depends on what type of product you’re making and which metal best suits your needs. stainless steel may be more expensive upfront, but its long-term benefits may make up for the initial cost difference in the end.

Is aluminum or stainless steel better?

It really depends on the application. aluminum is generally more lightweight than stainless steel and has better corrosion resistance, making it an ideal choice for outdoor applications. However, stainless steel offers higher strength and durability, making it a better option in situations where high performance is required. Ultimately, which material is best for your project will depend on your specific needs and requirements. We recommend doing some research into both materials to make sure you select the right one for the job!

What lasts longer aluminum or stainless steel?

It really depends on the environment and how they are used. Generally speaking, stainless steel is known to be more durable than aluminum because it is corrosion-resistant and can withstand tougher conditions. However, aluminum can last longer if properly maintained in a milder environment. For example, anodized aluminum can have a lifespan of up to 50 years depending on the climate, whereas stainless steel may not last as long without additional protection against corrosion or other factors. Ultimately, it’s important to consider all aspects when making your decision about which material will best suit your needs.

Does aluminum or stainless steel scratch easier?

It really depends on the type of aluminum and stainless steel. Generally speaking, softer metals are more prone to scratching than harder metals. Aluminum is usually considered a softer metal compared to stainless steel, so it will usually scratch easier than stainless steel. However, this varies depending on the grade and alloy of both materials. For example, certain grades of anodized aluminum are much harder than some types of stainless steel. When comparing two specific metals for scratch resistance, you should always check their hardness ratings first.

Useful Video: 10 Differences Between Aluminum and Stainless Steel

Conclusion

In the end, both stainless steel and aluminum have their own unique benefits and drawbacks. If you’re trying to decide which material is right for your project, it’s important to consider all of the factors involved.