Aluminum has been a popular building material for good reasons. It is lightweight, corrosion-resistant, and easy to install. Besides, different finishes can be applied to it, including an embossed one. This finish, in particular, adds a touch of style and elegance to aluminum products.

Stucco embossed aluminum sheets are a perfect choice for both industrial and decorative purposes. Are you looking for a reliable, durable, and elegant material for your construction project? Then stucco embossed aluminum sheets might be the answer. You might be asking yourself- what are these sheets? How do they differ from standard ones? In this blog post, we would delve into everything you need to know about stucco embossed aluminum sheets.

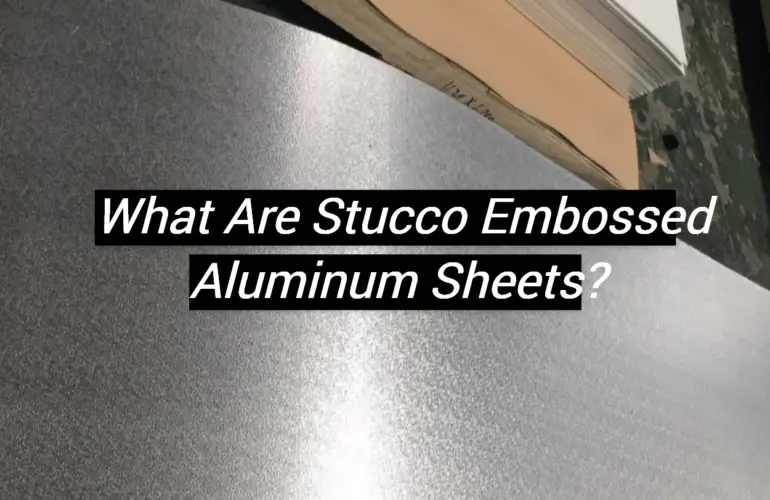

What Are Stucco Embossed Aluminum Sheets?

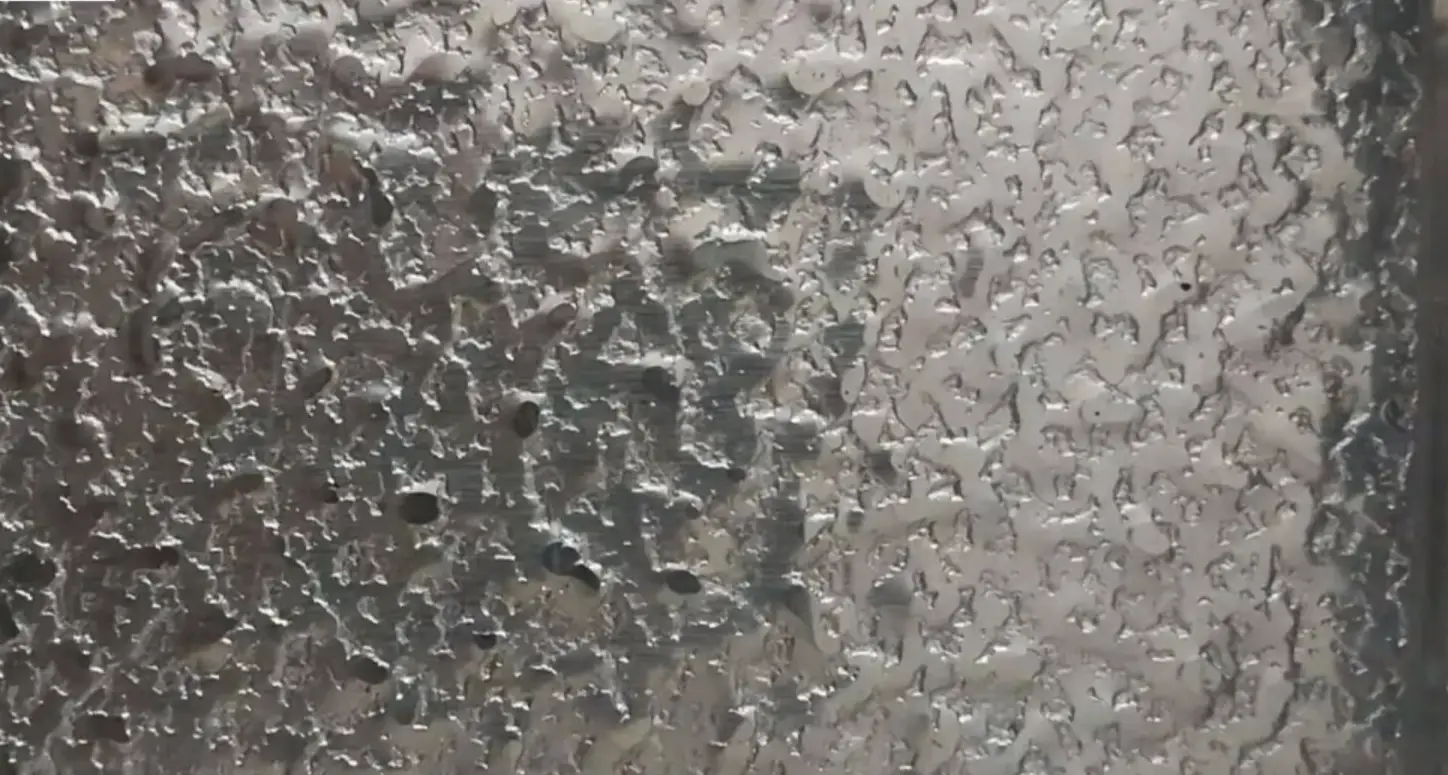

A stucco embossed sheet is a type of aluminum sheet that features a pattern similar to the textured tiles that you see on stucco walls. The design gives the sheet strength and alluring aesthetics. These designs are produced by embossing the sheet with diamond-shaped or square-shaped patterns and then applying a coating of paint or stucco to increase the durability. [1]

One significant benefit of stucco embossed aluminum sheets is their durability. Due to their textured surface, they are resistant to scratches caused by regular wear and tear. They are also waterproof, which makes them an excellent choice for outdoor projects.

The embossed texture also provides a slip-resistant surface, making it perfect for areas of the building where walking frequently occurs, especially in commercial areas, hospitals, and schools.

The installation process of stucco embossed aluminum sheets depends on the intended use. You need to follow the manufacturer’s guidelines to ensure that it is installed appropriately. Standard installation tools include a drill, cutter, pliers, a measuring tape, and screws. You may need extra tools depending on the installation requirements or the intended use.

Stucco embossed aluminum has several benefits that make it a preferred choice in different sectors such as construction, transportation, packaging, and appliance manufacturing.

Firstly, the embossed pattern masks minor surface imperfections, making it more aesthetically appealing and hiding dents and scratches that are more visible on smooth aluminum.

Secondly, it improves the sheet’s rigidity, making it an ideal material for applications that require dimensional stability, such as roofing and siding.

Additionally, stucco embossed aluminum has a higher resistance to scratch and wear, providing a more durable and low-maintenance product.

Stucco embossed aluminum sheets are widely available from a variety of suppliers, including online retailers. When shopping for sheets, be sure to look for a supplier that offers high-quality products and excellent customer support. Ask for samples and specifications to ensure that your chosen product meets your specific needs.

How Are Stucco Embossed Aluminum Sheets Made?

Stucco embossed aluminum sheets are quite popular in the construction industry due to their durability, corrosion resistance, and easy maintenance. These sheets are specially designed to withstand harsh weather conditions and protect the underlying surfaces. Here are the steps which explain how stucco embossed aluminum sheets are made.

Step 1: Casting

The first step in making stucco embossed aluminum sheets is to cast the raw material into the desired form. Casting involves pouring molten aluminum into a mold that is created based on the required dimensions and specifications. After casting, the aluminum is allowed to solidify and cool down to the required temperature.

Step 2: Rolling

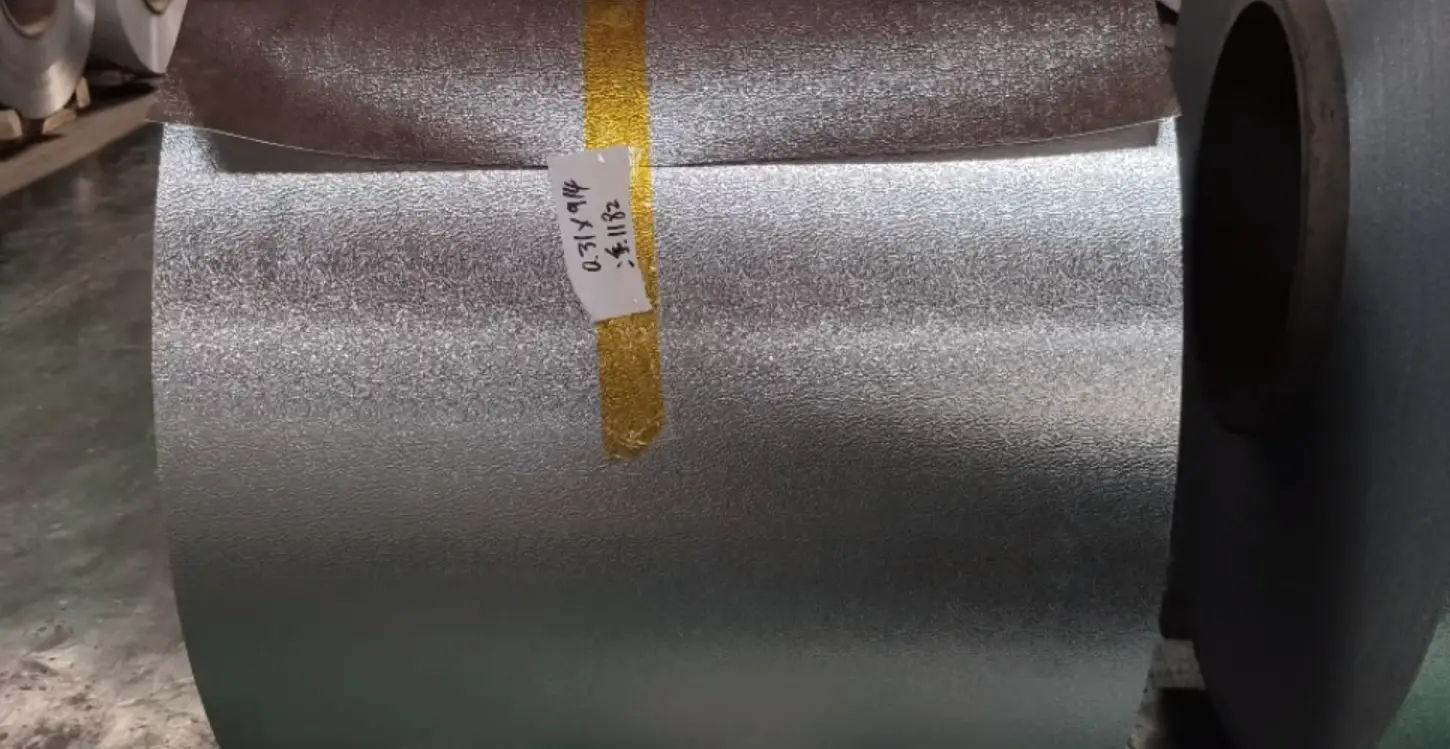

Once the aluminum has been cast, it is then rolled into large cylinders using specialized machinery to create a continuous strip. The rolling process helps to refine the shape and texture of the aluminum and also increases its strength. Depending on the required thickness and width of the stucco embossed aluminum sheet, the rolling process might be repeated several times.

Step 3: Annealing

After rolling, the aluminum strip is annealed to help improve its workability and reduce its overall stress and strain. Annealing involves heating the aluminum strip to a specific temperature, holding it there for a set amount of time, and then slowly cooling it down. This process also helps to improve the final product’s mechanical and physical properties.

Step 4: Surface Preparation

Before stucco embossed aluminum sheets can be created, the aluminum strip must first go through a surface preparation process. During this process, the strip is thoroughly cleaned and degreased to ensure that there is no dirt, grease, or other contaminants present on the surface. This helps to ensure that the stucco embossed pattern is uniform and precise.

Step 5: Stucco Embossing

The final step in the manufacturing process involves embossing the aluminum sheet with a stucco pattern. This is done using specialized machinery that presses a patterned roller onto the surface of the aluminum. This process creates a raised pattern on the surface of the aluminum sheet that can help to improve its appearance as well as its durability and resistance to wear and tear.

Best Ways of Using Stucco Embossed Aluminum Sheets

Stucco embossed aluminum sheets possess a unique aesthetic appeal and are an excellent option for any building project, whether residential or commercial. These sheets come in various sizes and styles, making them a versatile material that can be put to many uses.

Interior Design: Stucco embossed aluminum sheets are an excellent addition to any modern interior design project. These sheets can give your walls or ceilings an elegant, sleek, and modern look. They are an economical alternative to tiles or stone veneers and can easily add texture and depth to any space. You can use these sheets as a backsplash in your kitchen, an accent wall in your bedroom, or a feature wall in your living room. The possibilities are endless.

Building Cladding: Stucco embossed aluminum sheets are also a great option for exterior cladding. Their durability, light-weight, and resistance to weather conditions make them ideal for use as external panels. Architecturally, they can add a different dimension to any building, acting as a sound barrier, adding insulation, or providing fire resistance. The aluminum material is available in various grades and finishes, including painted, anodized, and mill finish, to suit your desired style.

Roofing: Stucco embossed aluminum sheets are an excellent option for roofing. Unlike traditional roofing materials such as clay tiles, slate, or asphalt shingles, stucco embossed aluminum sheets are lightweight, corrosion-resistant, and energy-efficient. In addition to this, they require little maintenance. They are perfect for flat roofs, dome-shaped roofs, and low-slope roofs.

Decorative Elements: Stucco embossed aluminum sheets can be used to produce a range of decorative elements such as signage, lampshades, room dividers, and furniture. They can add texture and depth to any space or structure, just like other textured metal sheets. These sheets are suitable for various applications due to their durability, corrosion resistance, and texture. [1]

Kitchen Appliances: Stucco embossed aluminum sheets are also used in the manufacture of appliances such as refrigerators, ovens, and microwaves. They provide an attractive and durable finish. The textured nature of the sheet not only makes appliances look great but also helps in reducing the appearance of scratches, dents, and other visible imperfections.

How to Maintain Stucco Embossed Aluminum Sheets?

Stucco embossed aluminum sheets do not require too much maintenance. A simple cleaning procedure is needed to keep your sheets looking great. All you need is a soft cloth or a sponge, warm water, and a cleaning agent. Avoid using abrasive or harsh chemicals that may damage the surface of the sheets. Inspect your stucco embossed aluminum sheets frequently to check for any damage and repair it promptly.

Stucco embossed aluminum sheets are designed to be robust and durable, but even the most robust materials need some form of maintenance. To keep their looks and quality, it’s essential to take proper care of them. Here are some steps that will help you better understand the basic rules of stucco embossed aluminum sheets maintenance.

Step 1: Regular Cleaning

The easiest and most important step in caring for your stucco embossed aluminum sheets is cleaning them regularly. Failure to clean your surfaces will leave your aluminum sheets looking shabby and can lead to corrosion. A simple mix of warm water and soap, wiped gently on the stucco surface with a soft cloth is enough to do the trick. Avoid using rough tools like steel wool or abrasive cleaners that may scratch the surface and dull its texture.

Step 2: Add a Protective Layer

A protective layer or coating adds a guard to your stucco embossed aluminum sheets, shielding it from unwanted scratches, fading, and other elements. This layer could be as simple as a coat of wax applied annually to prevent the cold effects of harsh weather, such as chipping and cracking.

Step 3: Address Dents and Scratches

Even the sturdiest aluminum sheets may get small dings and scratches over time. These dents may seem small, but with time, they could degenerate quickly and lead to corrosion. For minor dents and scratches, DIY repair is possible. Apply a baking soda-water paste on the area and buff slowly with a soft cloth to smoothen the area. However, if the dents are large or appear critical, consider hiring a professional technician to handle the repair.

Step 4: Avoid Exposure to Harsh Elements

Stucco embossed aluminum sheets are designed for use in harsh weather conditions, but an overabundance of exposure can have disastrous consequences for longevity. Keep the sheets away from moisture, prolonged sun exposure, and extreme heat to keep them looking their best. If the aluminum is outdoors, ensure it is sealed and installed correctly, and avoid exposing it to acidic materials, such as chemicals.

Step 5: Inspect your Surfaces Regularly

Finally, perform periodical checks on your stucco embossed aluminum sheets, looking out for cracks, dents, and other problems. Early detection of defects is crucial to prevent further degradation of the surface and costly repairs.

Stucco embossed aluminum sheets are robust and designed to last, but even the strongest materials require some maintenance. By cleaning your surfaces regularly, adding a protective layer, addressing dents and scratches, avoiding exposure to harsh elements, and inspecting your surfaces regularly, you can prolong your aluminum sheet’s life and keep them looking pristine. By following these tips, you can ensure your stucco embossed aluminum sheets serve you for the long haul.

FAQ

How thick is aluminum stucco sheet?

Aluminum stucco sheets come in different thicknesses, ranging from 0.1mm to 3.0mm. The thickness you choose depends on the intended use. If you want to use it for insulation purposes, you can opt for a thicker sheet. A thicker sheet provides better insulation compared to a thinner one. Similarly, a thinner sheet is suitable for decorative purposes. When choosing the thickness, you need to strike a balance between the benefits and the cost.

What is stucco Embossed aluminum?

Stucco embossed aluminum refers to aluminum sheets or coils that have a raised pattern featuring grooves or depressions that resemble a stucco wall. Stucco is a textured finish that is popular in housing construction, and it creates visual interest and depth to plain aluminum products. Its ability to mask minor surface imperfections, increase sheet rigidity and wear resistance make it ideal for various sectors, and basic maintenance is all that is required to keep it looking new for years.

How to apply stucco embossed aluminum sheets?

If you need to apply stucco embossed aluminum sheets, you should measure and prepare the surface, apply adhesive, install the sheets, cut them if necessary, and caulk and paint for a perfect finished look. [2]

Where to buy stucco embossed aluminum sheets?

Start by doing thorough research online, asking colleagues or professionals, checking your local hardware stores, attending trade shows, or purchasing directly from manufacturers or wholesalers. Finally, prioritize quality and durability when purchasing stucco embossed aluminum sheets.

Why choose stucco embossed aluminum sheets?

There are many reasons why stucco embossed aluminum sheets are a great option for transforming your space. For one, they are incredibly lightweight, which makes them easy to handle and install. They are also resistant to corrosion and weathering, which makes them ideal for outdoor use. And because they are made from aluminum, they are highly durable and can withstand the test of time.

What are some common uses for stucco embossed aluminum sheets?

Stucco embossed aluminum sheets can be used in a variety of applications, from roofing and siding to decorative accents and interior design. They are also popular in the transportation industry, where they are used for trailer roofs and walls. In homes and businesses, they can be used to create unique wall panels, accent pieces, and backsplashes. And because they come in a variety of colors, they can be customized to suit your aesthetic preferences. [1]

Useful Video: Stucco embossed aluminum sheet

Conclusions

If you’re looking for an easy and affordable way to give your space a fresh new look, stucco embossed aluminum sheets are definitely worth considering. They offer a unique texture that can add depth and dimension to your walls, ceilings, and other surfaces. In addition, stucco embossed aluminum is a beautiful and durable material that provides endless possibilities for design and application. At its core, it is just like any other aluminum, but the embossing process adds character and texture that makes it stand out from the crowd. Its ability to mask minor surface imperfections, increase sheet rigidity and wear resistance make it ideal for various sectors, and basic maintenance is all that is required to keep it looking new for years.

Stucco embossed aluminum sheets are a durable and versatile option for your construction projects. They are waterproof, scratch-resistant, and slip-resistant, making them suitable for both indoor and outdoor use. Proper installation and maintenance will ensure that your sheets look beautiful and remain functional for a long time. If you need stucco embossed aluminum sheets for your project, reach out to reputable manufacturers or suppliers. They can provide you with the guidance, certification, and materials that you need to ensure a quality finish.

References:

- https://aaluminum.com/blog/stucco-embossed-aluminum-sheets/#:~:text=Stucco%20embossed%20aluminum%20sheets%20are,vehicle%20trim%2C%20and%20kitchen%20appliances.

- https://www.alumhm.com/a/the-application-of-stucco-embossed-aluminum-sheet.html