Are you looking for precise, high-quality craftsmanship in your aluminum fabrication projects? If so, then laser cutting might be the ideal solution for you. This incredible process is capable of exquisite results on a variety of materials – and yes, that includes aluminum. In this blog post, we’ll take a look at how laser cutting works with aluminum to create intricate and durable products. We’ll discuss the features offered by this modern technique, as well as tips on choosing the best way to cut aluminum according to your project needs. So let’s dive in and discover why more people are turning to laser cutting when it comes to their metal fabricating projects!

What Are the Characteristics of Aluminum?

Aluminum is a lightweight yet strong metal that can be easily formed into many shapes and sizes. It is much lighter than other metals, such as steel or copper, making it well suited for applications where portability is important.

It is also highly resistant to corrosion, so it’s commonly used in applications where durability and longevity are essential. Aluminum has excellent electrical conductivity which makes it an ideal material for use in various electrically-powered objects like airplane parts, electronic gadgets, and car components.

It’s also prized for its ability to reflect light and heat, making it popular as siding on homes or other buildings. In addition, its thermal conductivity allows heat to dissipate quickly when exposed to air currents, making aluminum a great choice for cooling systems. Its reflective surface helps reduce the amount of heat that is absorbed by objects or surfaces, making it great for use in insulation. With all these advantages, aluminum remains one of the most common metals used across multiple industries. [1]

Aluminum is also highly recyclable and sustainable, making it an environmentally friendly choice for many projects. Its malleability allows aluminum to be used in a variety of shapes and sizes, from sheets to rods and tubes.

What Are the Methods of Cutting Aluminum?

It can be cut with the help of plasma, laser and water cutting tools. Each method has its own unique advantages and disadvantages. Let’s take a look at them:

- Plasma Cutting: This method is quite versatile and can be used for a wide range of materials including aluminum, stainless steel, brass, copper and even plastics. Plasma cutting uses an electrical arc to melt the material being cut and blow it away with compressed air or inert gas. It’s very accurate and has minimal heat distortion. The downside is that plasma cutting creates a lot of smoke, sparks, and noise. [3]

- Laser Cutting: Laser cutting is a highly precise method that produces smooth edges without burrs or defects. This makes it ideal for complex shapes and designs. It’s also relatively faster than other methods while still producing impressive accuracy results. However, laser cutting machines require high-powered lasers which are expensive to operate. [4]

- Water Cutting: This method uses a high-pressure stream of water mixed with an abrasive material to cut through aluminum. It creates smooth edges with minimal heat distortion and is relatively faster than other methods, making it ideal for large batch production runs. The downside is that this method requires a lot of energy to operate, making it an expensive option. [5]

Aluminium Cutting Challenges

Aluminum cutting can be a difficult process due to its unique properties. Aluminum is a soft yet strong metal that is resistant to heat and corrosion, making it a popular choice for many construction projects.

However, the challenges of aluminum cutting are well-known among professionals in the metalworking industry. The following outlines some common issues encountered during aluminum cutting:

- Heat Build Up – Due to its low thermal conductivity, aluminum has difficulty dissipating heat during the cutting process. This can lead to increased friction and subsequent tool wear which can result in poor quality cuts or even breakages of tools used. To reduce this risk, proper cooling techniques must be employed during the cutting process.

- Tool Wear – Aluminium’s hardness and strength can cause excessive wear on cutting tools, making them dull after a short period of use. This is why it is essential to use quality tools made from carbide or high-speed steel for best results.

- Difficult To Machine – Aluminium can be difficult to machine due to its metal properties which can lead to poor surface finish or burrs. This problem can be solved by using the right cutting speeds and feeds as well as employing chip breakers during the process.

- Deformation – Due to its physical characteristics, aluminum can easily deform when exposed to heat during the machining process. To reduce this risk, proper clamping techniques should be employed in order to keep pieces stable while they are being cut.

- High Cost of Machining – Aluminium is known to be expensive when compared to other metals, making it difficult for some businesses to justify the cost of machining. The high cost can also make it difficult to find reliable suppliers who can provide quality materials at affordable prices. [6]

Is Laser Suitable for Cutting Aluminum?

Laser cutting provides a fast and more accurate way to cut aluminum compared to traditional methods such as sawing or punching. The process can create intricate designs with smooth edges and does not require any clamping of the material being cut.

Furthermore, lasers can be accurately programmed to generate complex geometrical shapes which makes them a great choice for creating highly detailed components with precision accuracy.

Laser cutting also produces minimal heat affected zones which preserves the integrity of the material being cut.Key Advantages of Aluminum Laser Cutting

- Precise and accurate cutting – Aluminum laser cutting has the capability to cut through metals with maximum precision. The laser beam is highly focused and can reach incredibly tight tolerances that traditional cutting methods are unable to achieve. This allows for extremely complex shapes, designs, and intricate details that would otherwise be impossible to produce.

- Cost efficiency – Laser cutting of aluminum is much more cost effective than other metal fabrication methods due to its high speed, accuracy, and low waste. It requires minimal setup time compared to conventional techniques which can add up over the course of larger projects.

- Quiet Operation – As opposed to mechanical saws or shears used in traditional metal fabrication processes, laser cutting does not require any noise-producing machinery. This makes it ideal for projects in close proximity to residential areas or other sensitive environments.

- High Quality Edges – Laser cutting aluminum provides a cleaner, smoother edge finish than traditional methods, resulting in higher quality parts and components.

- Versatility – Aluminum laser cutting is highly versatile due to its ability to cut intricate shapes and patterns with ease. It is suitable for a wide variety of applications such as automotive, aerospace, medical, electronic enclosures, signs and more! Its flexibility makes it an ideal choice for complex projects where performance is critical. [7]

Choosing the Suitable Laser Cutting Machine

There are several factors to consider:

- Laser power and type: The laser power, type of laser (CO2 or fiber), and the maximum cutting speed will all influence the quality of cuts, speed of production, and cost of operation. To determine the right machine for your needs, you’ll need to consider what type of material you want to cut, how thick it is, and the size of the pieces that need to be cut.

- Footprint: The physical size of the machine is important when considering space requirements in a workshop. Make sure you have enough room for your specific machine before purchase.

- Cost: Evaluate both initial costs associated with purchasing a laser cutter as well as ongoing operational costs such as materials used, maintenance and electricity.

- Maintenance: It is essential to factor in the time and cost of regular maintenance for any machine you purchase, as this will help to ensure its longevity.

- Safety: It is vital to consider the safety of any laser cutting machine before purchase. Ensure you have adequate ventilation systems, protective eye-wear and fire suppression systems in place for your specific needs.

3 Types of Laser Cutting Equipment for Working with Aluminum

The process of laser cutting allows manufacturers to create precise and intricate shapes with less waste than other manufacturing methods, making it ideal for production runs and custom projects.

There are three main types of laser cutting equipment used for working with aluminum:

CO2 Lasers

CO2 lasers have been the most commonly used type of laser cutter since they were first developed in the 60s. They are made from gas sealed in glass tubes filled with a mixture of gases such as carbon dioxide, helium, and nitrogen. These lasers emit infrared light (10,600 nanometers) which cuts through materials like aluminum easily. The heat generated is also low enough that it will not damage the material after cutting.

Nitrogen Lasers

These are similar to CO2 but they are much more powerful and have a shorter wavelength (337 nanometers). These types of laser cutters produce a high-intensity beam that passes through nonmetals like aluminum with ease, allowing manufacturers to create intricate shapes quickly and accurately. However, nitrogen lasers require greater energy input than CO2 lasers and generate more heat, making them suitable for thicker materials or larger pieces of aluminum but less so for thinner pieces.

Fiber Lasers

The most recent development in laser cutting technology is fiber lasers which use optical fibers as their source of light. These lasers produce a narrow beam of light that is extremely precise and focused, making them ideal for cutting thinner sheets of aluminum with high accuracy. Fiber lasers also require less energy than other types of laser cutters while generating less heat, resulting in longer lasting parts with fewer deformations due to the heat. [8]

When using any type of laser cutter on aluminum, it’s important to take certain precautionary measures to ensure safety and optimal results.

Basics Steps of Laser Cut Aluminum Process

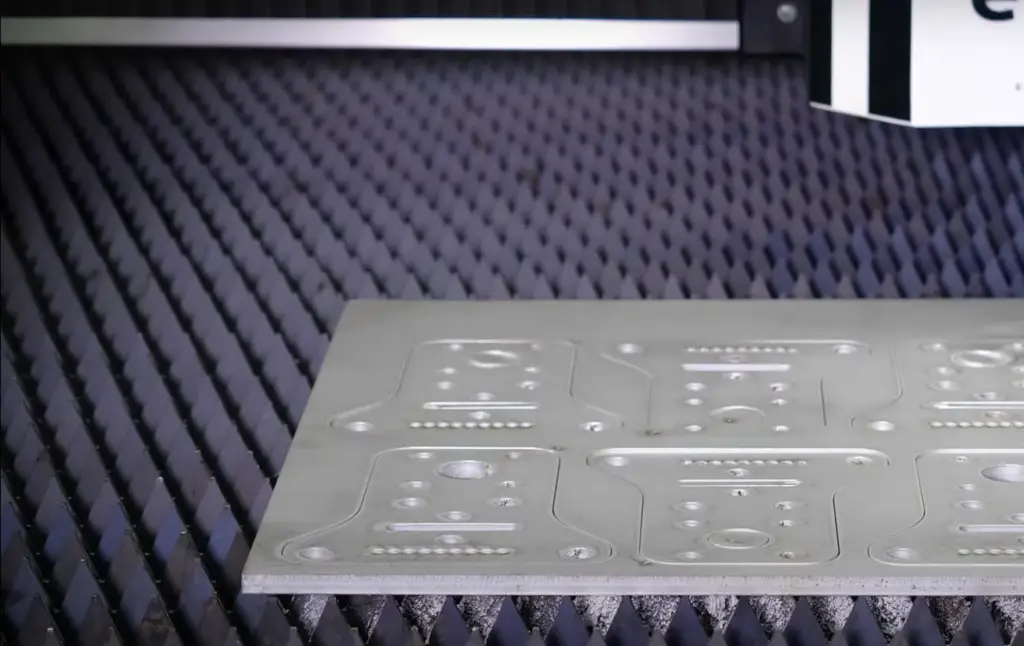

Laser cutting aluminum is an increasingly popular method for fabricating metal components. This process uses a high-powered laser beam to cut through the material, producing highly precise and intricate designs with excellent edge quality.

The aluminum laser cutting process is a precise and reliable method to cut through various thicknesses of aluminum sheets. The basic steps include the following:

Setting up the laser machine

A specialized laser cutter with a particular type of optics should be used for aluminum laser cutting. Additionally, it is important to ensure that all safety precautions are observed when setting up the machine, including using proper ventilation and wearing protective eyewear.

Loading the Aluminum Sheets

Next, the aluminum sheet needs to be loaded into the work area of the laser cutter.

The size and thickness of the material will determine how much power is needed to make a successful cut. If possible, use a clamping mechanism to keep the sheets in place during cutting.

Programming the Machine

Once the machine is set up and the aluminum is loaded, a program must be created to guide the laser beam through its movements. This can include setting various parameters such as speed, power, and focus of the beam.

Cutting Process

After programming is complete, it is time to begin the aluminum laser cutting process. During this phase, it is important to keep an eye on the progress of the cut and monitor for any irregularities or problems that may occur with the sheet or machine itself. If necessary, adjustments can be made in real-time to ensure maximum accuracy of each cut.

Finishing Steps

The final step in aluminum laser cutting is to inspect the finished product for any problems or discrepancies. This can include checking the edges of each cut for burrs, warping, and other irregularities that may have occurred during the process. [9]

7 Tips and Tricks for Using Aluminum Laser Cutting Machine

By following these tips and tricks, you can maximize the efficiency of your aluminum laser cutting machine and ensure high-quality results every time:

- Make sure your workspace is clean and organized before starting the process of cutting aluminum materials. Removing any debris or dirt from the area will help ensure that you get accurate cuts and avoid mistakes due to dust particles blocking the path of the laser beam.

- Choose the right power setting – It is important to choose the right power setting for your aluminum laser cutting machine. The right setting will ensure that the material you are working with gets cut without damaging it, as well as ensuring a clean and accurate cut overall.

- Make sure to keep the focal point of the laser in focus at all times during operation in order to achieve accurate results every time. If you notice that the cuts are not uniform or precise enough, adjust the focal point accordingly.

- Use cooling systems – Many aluminum laser cutting machines come with built-in cooling systems which should be used whenever possible to reduce the heat generated during the process and prevent any potential damage to the material being worked on.

- Preheat or pre-treat aluminum material – Preheating or pre-treating aluminum materials prior to using a laser cutter can help improve its ability to absorb higher powered laser beams and result in faster and more efficient cutting.

- Inspect the material after cutting – Once you’ve finished cutting your aluminum material, it is important to inspect it for any signs of potential damage or irregularities that might have been caused by the laser cutter. This is especially important when dealing with materials such as aluminum which can be vulnerable to heat-related issues.

- Follow precautions – When working with an aluminum laser cutter, it is important to take all necessary precautions to ensure safety and avoid any potential accidents from occurring. This includes wearing protective gear such as gloves and goggles, using appropriate ventilation systems, and ensuring the area being worked on is clear from any flammable materials or debris. [10]

Safe Operation of Aluminum Laser Cutting Machine

When operating a laser cutter there are some vital safety precautions that should be taken in order to ensure the safety of both personnel and equipment.

First and foremost it’s essential that operators wear protective eyewear at all times while working with the machine. The intense beam of light used in the cutting process can be highly damaging to eyesight if exposed without adequate protection.

Appropriate fire extinguishers should also be readily available near the machine in case of an emergency.Regular maintenance is essential in order to ensure that aluminum laser cutters are working correctly and safely at all times. This includes ensuring that all safety guards are properly attached and functioning as they should. It’s also important to inspect any ventilation systems regularly and ensure that they remain clear of debris and dust buildup that may interfere with their proper operation.

By taking these simple steps operators can rest assured that their aluminum laser cutting machines will continue to perform safely for years to come.

FAQs

What kind of laser can cut aluminum?

Aluminum can be cut with a variety of lasers, including CO2 lasers and fiber laser cutting machines. CO2 lasers are the most common type of laser cutter used for aluminum due to their precision and efficiency.

What are the advantages of laser cutting aluminum?

Laser cutting offers several key advantages. These are precision, speed, flexibility, cost savings, and minimal material wastage. Laser cutters can produce highly accurate parts with complex shapes quickly and efficiently, making them ideal for a variety of applications in many industries. Additionally, laser cutting eliminates time-consuming manual processes and is more economical than traditional machining methods.

What can not be cut by a laser?

Certain materials are not suitable for laser cutting due to their physical or chemical properties. They include rubber, plastics, and metals such as titanium and zirconium. Additionally, certain types of composites are also not suited for this type of cutting.

What are the problems with laser cutting aluminum?

Despite the advantages, there is a set of issues. For one, high heat from a laser beam can cause warping in thinner sheets of metal and burns marks on thicker metal. Due to the high temperatures involved, there may be an increased risk for fires if proper safety protocols and equipment are not in place. Moreover, lasers can create hazardous fumes which must be contained and properly disposed of to prevent air pollution or contamination.

Useful Video: 30kW 10MM ALUMINIUM CUTTING | EAGLE LASERS

Bottom Line

In conclusion, laser technology allows you to quickly cut out parts of any complexity and in any quantity. The accuracy and quality of laser cutting of aluminum sheet is superior to cutting with a mechanical tool.

Aluminum laser cutting is an innovative and efficient way of manufacturing metal parts with precision and accuracy. It is an excellent and efficient tool for manufacturing businesses or small projects. The numerous advantages make it ideal for a range of uses. Its fast speed allows quick results in production, while its accuracy allows for high precision on the finished product.

Despite these benefits, precautions should always be taken when using lasers to cut aluminum as the heat generated during the process can cause a significant amount of damage. If you’re interested in investigating this potentially powerful production capability for your bottom line more deeply, try looking into a local vendor that specializes in aluminum laser cutting services or contact an industry professional – after all, it could turn out to be a great investment!

References:

- https://www.laminazionesottile.com/en/blog/what-is-aluminum-here-are-its-most-important-characteristics/

- https://www.webmd.com/balance/how-to-recycle-aluminum

- https://microstep.com/en/Expert-know-how/Plasma-cutting

- https://www.troteclaser.com/en/learn-support/faqs/how-to-laser-cut

- https://www.iqsdirectory.com/articles/water-jet-cutting.html

- https://jbcmachine.com/challenges-of-aluminum-machining

- https://www.laser-ing.com/blog/laser-metal-cutting-key-advantages

- https://www.heatsign.com/how-to-choose-the-right-laser-cutting-machine/

- https://www.instructables.com/Laser-Cutting-Basics/

- https://makerdesignlab.com/tutorials-tips/laser-cutting-beginners-guide/