Choose the Best Aluminum Floor Jack

Customer’s Choice: the Best Rated Aluminum Floor Jacks

21 users answered this survey. Please help us improve this review!

When it comes time to get your car up in the air, you’ll want to make sure you have the right equipment. A Floor Jack is an essential piece of machinery for any DIY mechanic, and there are a few different types on the market. If you’re looking for an Aluminum Floor Jack, then you’ve come to the right place. This article will answer some common questions about these jacks and review some of the best products on the market. It will also provide some tips on how to use them safely and efficiently.

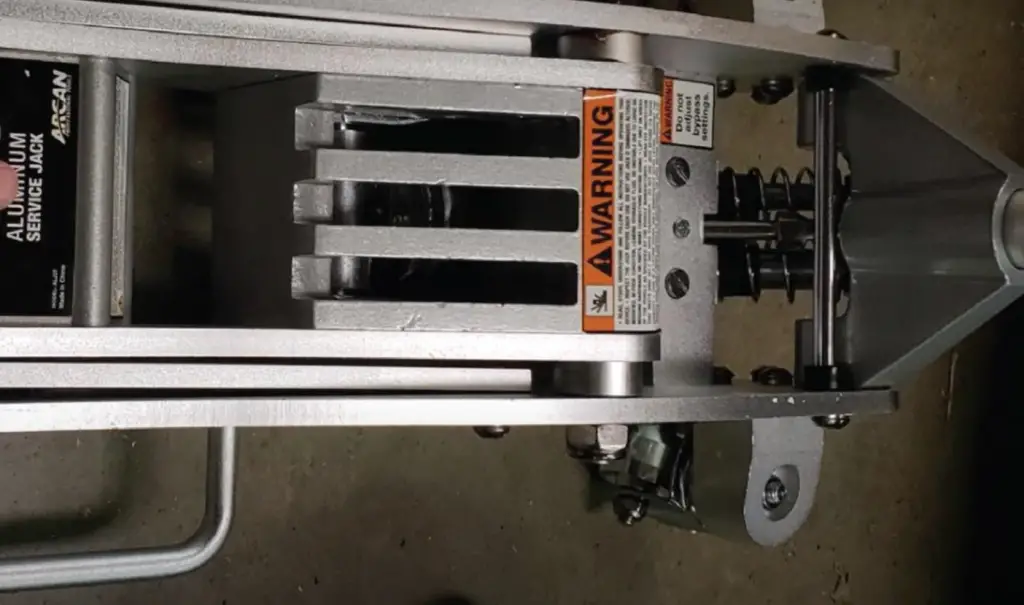

Arcan 3-Ton Quick-Rise Aluminum Floor Jack

If you need a floor jack that can handle heavy loads quickly and efficiently, look no further than the Arcan 3-Ton Quick-Rise Aluminum Floor Jack.

If you need a floor jack that can handle heavy loads quickly and efficiently, look no further than the Arcan 3-Ton Quick-Rise Aluminum Floor Jack.

Plus, the rubber pad ensures chassis torsion control and the reinforced lifting arm allows for easy maneuverability. So, whether you’re working on a big project or just need a little extra help getting your car lifted, the Arcan 3-Ton Quick-Rise Aluminum Floor Jack is up to the task.

NOS 3-Ton Aluminum Service Jack NSJ0301

Introducing the NOS 3-Ton Aluminum Service Jack NSJ0301. This jack is perfect for roadside emergencies or garage use, with a lifting capacity of 3 tons and a height range of 9.5 cm to 45 cm.

Introducing the NOS 3-Ton Aluminum Service Jack NSJ0301. This jack is perfect for roadside emergencies or garage use, with a lifting capacity of 3 tons and a height range of 9.5 cm to 45 cm.

And for rapid lifting, the dual pump system is unbeatable. Plus, the 2-piece handle with bumper pad makes it comfortable to use. So, don’t be caught without this essential piece of equipment – order your NOS 3-Ton Aluminum Service Jack NSJ0301 today!

Arcan 2-Ton Quick-Rise Aluminum Floor Jack

The Arcan 2-Ton Quick-Rise Aluminum Floor Jack is the perfect choice for anyone looking for an easy to maneuver and durable floor jack.

The Arcan 2-Ton Quick-Rise Aluminum Floor Jack is the perfect choice for anyone looking for an easy to maneuver and durable floor jack.

Additionally, the side-mount handle allows for convenient jack positioning, and the quick-rise feature quickly raises the floor jack saddle. With a load capacity of 2 tons, the Arcan 2-Ton Quick-Rise Aluminum Floor Jack is the perfect choice for any car enthusiast or professional mechanic.

BIG RED Torin Hydraulic Low-Profile Aluminum and Steel Racing Floor Jack

The BIG RED Torin Hydraulic Low-Profile Aluminum and Steel Racing Floor Jack is a top-quality product that is perfect for general or specialty use. It is made of durable, high-strength alloy steel and aluminum, and has a lifting capacity of 1.5 Tons.

The BIG RED Torin Hydraulic Low-Profile Aluminum and Steel Racing Floor Jack is a top-quality product that is perfect for general or specialty use. It is made of durable, high-strength alloy steel and aluminum, and has a lifting capacity of 1.5 Tons.

The jack also includes rubber pads to prevent it from slipping, and only requires 6 strokes to reach its maximum height. With its aluminum frame and lift system, the BIG RED Torin Hydraulic Low-Profile Aluminum and Steel Racing Floor Jack is perfect for use with low-profile vehicles. The multilayer powder coating ensures that the jack will withstand even the most strenuous use.

Sunex 6603ASJ 3-Ton Aluminum Lift for cars

The Sunex 6603ASJ 3-Ton Aluminum Lift is a top-of-the-line car lift that is perfect for both professional and home garage use. This lift is made of aircraft-grade aluminum and features rapid rise technology, making it incredibly easy to use.

The Sunex 6603ASJ 3-Ton Aluminum Lift is a top-of-the-line car lift that is perfect for both professional and home garage use. This lift is made of aircraft-grade aluminum and features rapid rise technology, making it incredibly easy to use.

Additionally, the Sunex 6603ASJ 3-Ton Aluminum Lift comes with a rubber saddle pad and foam bumper pad to protect your vehicle from scratches. It also has a low lifting height of 9.5 cm and is equipped with wide track wheels for easy maneuverability.

Buyer’s Guide

What is an Aluminum Floor Jack used for?

An Aluminum Floor Jack is a device that is used to lift up the body of a vehicle so that you can gain access to the underside. This is usually done to perform maintenance or repairs, but it can also be useful for simply taking a closer look at the bottom of your car.

There are many different types of floor jacks available on the market, but aluminum models tend to be some of the most popular. This is because they offer several advantages over other materials, including being lighter in weight and more durable.

It is important to keep in mind that there are two basic types: hydraulic and mechanical. Hydraulic jacks use a fluid to power the lifting mechanism, while mechanical jacks rely on gears and levers.

Hydraulic jacks are typically more expensive than their mechanical counterparts, but they are also easier to use. This is because all you need to do is pump the handle up and down to raise or lower the vehicle. Mechanical jacks, on the other hand, require you to turn a crank to operate them.

If you plan on using your floor jack frequently, then a hydraulic model may be worth the investment. However, if you only need it for occasional use, a mechanical jack will likely suffice [1].

What to Consider When Choosing the Best Aluminum Floor Jack?

Vehicle Type

The first thing you need to consider when choosing an aluminum floor jack is the type of vehicle you will be using it on. If you have a smaller car, then you won’t need as much lifting capacity as someone who has a larger SUV or truck.

Another thing to keep in mind is that some jacks are only designed for certain types of vehicles. For example, some jacks are specifically designed for use with SUVs and trucks. These jacks usually have a higher lifting capacity and may be more expensive than other types of jacks.

Manual vs. Electric

Another thing you need to consider when choosing an aluminum floor jack is whether you want a manual or electric model. Manual jacks can be operated by hand, while electric jacks need to be plugged into an outlet.

Electric jacks are more expensive than manual jacks, but they are also much easier to use. If you have a large vehicle, then an electric jack may be the best option for you.

Manual jacks are less expensive and can be used on any type of vehicle. However, they require more effort to operate and may not be as easy to use if you have a large vehicle [2].

Lifting Arm

Another thing to consider when choosing an Aluminum Floor Jack is the type of lifting arm. Some jacks have a single lifting arm, while others have two.

Single-arm jacks are less expensive and can be used on any type of vehicle. However, they require more effort to operate and may not be as easy to use if you have a large vehicle.

Double-arm jacks are more expensive but are much easier to use. If you have a large vehicle, then a double-arm jack may be the best option for you.

Height Range

You also need to consider the height range of the jack. The height range differs from one lifting tool to another. If you have a small car, look for an aluminum floor jack with a lower lifting capacity. On the other hand, if you drive a large SUV or truck, choose one with a higher lifting capacity to avoid damaging your vehicle.

Saddle Size

The size of the saddle is also an important consideration when choosing an aluminum floor jack. The saddle is the part of the jack that comes in contact with your vehicle and supports it while it is being lifted. This detail of the Aluminum Floor Jack is usually made of rubber to prevent slippage and protect your car’s paint job.

The size of the saddle should be appropriate for the size of your vehicle. If you have a small car, then you won’t need a large saddle. However, if you have a large SUV or truck, then you will need a larger saddle to support it properly.

Most jacks come with an adjustable saddle so that they can be used on different types of vehicles. If you only plan on using the jack on one type of vehicle, then you can save money by choosing a model with a fixed saddle. On average, most jacks have a saddle size of about 12 cm by 12 cm. However, some jacks may have a larger or smaller saddle depending on the specific model.

Handles and Rollers

Some Aluminum Floor Jacks come with handles and rollers while others do not. If you plan on using the jack in a garage or workshop, then you will probably want to choose a model that has handles and rollers.

Handles and rollers make it much easier to move the jack around. However, they are not necessary if you only plan on using the jack in your driveway or on the side of the road. Most jacks have handles that are about 30 cm long. The size of the roller varies from one model to another but is usually about 15 cm in diameter.

The handles can be constructed of two pieces that are hinged together or they can be one solid piece. The rollers can be made of plastic, metal, or rubber. The rollers should be able to rotate freely so that they can be moved in any direction.

Weight of the Jack

The weight of the jack is another important consideration. If you plan on using the jack in a garage or workshop, then you will probably want to choose a model that is easy to move around.

On the other hand, if you only plan on using the jack in your driveway or on the side of the road, then you won’t need to worry about moving it around. In general, lighter jacks are easier to move but they may not be as sturdy as heavier jacks.

Most Aluminum Floor Jacks weigh between 12 kg and 18 kg. Some models may be heavier or lighter depending on the specific design and construction.

Rust Resistance

Another important consideration is rust resistance. If you plan on using the jack in a garage or workshop, then you will probably want to choose a model that is made of aluminum, stainless steel, or has a powder-coated finish.

These materials are more resistant to rust and corrosion than other materials. On the other hand, if you only plan on using the jack in your driveway or on the side of the road, then you won’t need to worry about rust and corrosion.

However, some models may be made of aluminum or stainless steel.

Aluminum jacks are the lightest weight option but they are not as strong as steel jacks. Stainless steel jacks are very strong but they are also very heavy. Powder-coated jacks are a good compromise between strength and weight.

Powder-coated finishes come in different colors such as black, red, and blue. Some finishes are more resistant to corrosion than others. You should choose a finish that is appropriate for the environment in which you plan on using the jack.

Weight Capacity in Tons

The weight capacity is another important consideration. Most Aluminum Floor Jacks have a weight capacity of between two and four tons.

Some models may be able to lift more weight but they are usually more expensive. If you only plan on using the jack to lift your car, then you won’t need a model with a high weight capacity.

On the other hand, if you plan on using the jack to lift heavy equipment or machinery, then you will need a model with a higher weight capacity [4].

How To Bleed Your Jack Before Use?

If your jack isn’t working properly, it might need to be bled. To do this, you’ll need to:

- Find the bleeder valve on your jack. This is usually a small knob or lever near the base of the unit.

- Using a wrench or pliers, open the bleeder valve. You may need to turn it clockwise or counterclockwise, depending on the design of your jack.

- With the bleeder valve open, slowly pump the handle of your jack up and down until fluid starts dripping out of the valve. Once the fluid starts coming out, close the bleeder valve and test your jack to see if it’s working properly.

If you’re still having issues, you may need to repeat this process.

If you don’t bleed your jack, it might not lift properly or could even fail, which could lead to serious injury [5].

How To Use An Aluminum Floor Jack?

Using an Aluminum Floor Jack is relatively simple, but there are a few things you should keep in mind to stay safe:

- To begin, position the jack near the tire of the vehicle you want to lift. Make sure that the jack is on level ground and will not slip or roll while in use.

- Next, loosen the lug nuts on the wheel that you’ll be lifting. You don’t need to remove them completely, but you should be able to turn them by hand.

- Now it’s time to start lifting. Place the jack under the vehicle near the wheel that you want to lift. Slowly pump the handle until the wheel is off the ground.

- Once the wheel is lifted, remove the lug nuts and take off the tire. You can now proceed with whatever repair or maintenance you need to do.

When you’re finished, lower the vehicle back down and tighten the lug nuts before driving away.

There are a few things to keep in mind when using an Aluminum Floor Jack: always work on level ground, never exceed the jack’s capacity, and be careful when lowering a vehicle back down. With these tips in mind, you’ll be able to safely and easily use an Aluminum Floor Jack.

Filling a Car Jack With Hydraulic Oil

If your car jack isn’t working properly, it might need more hydraulic oil. Filling a car jack with hydraulic oil is a pretty simple process that only takes a few minutes. Here’s what you’ll need to do:

- Find the fill port on your car jack. This is usually located near the base of the jack.

- Remove the cap from the fill port and slowly pour hydraulic oil into the port until the oil reaches the full line.

- Replace the cap on the fill port and make sure it’s tight so no oil can leak out.

Now your car jack should be filled with enough hydraulic oil to work properly! If you’re still having trouble, though, you may need to replace the hydraulic fluid altogether [6].

Now your car jack should be filled with enough hydraulic oil to work properly! If you’re still having trouble, though, you may need to replace the hydraulic fluid altogether [6].

Comparison of Indicators for Choosing Aluminum Floor Jacks

When selecting an aluminum floor jack, several indicators should be considered to ensure a safe and efficient lifting experience. This table presents a comparison of various indicators to help you make an informed decision. The indicators include lifting capacity, minimum and maximum height range, weight, and handle length.

- Lifting Capacity (lbs): This indicates the maximum weight that the floor jack can safely lift. It is important to choose a floor jack with a lifting capacity that exceeds the weight of the vehicle or object you intend to lift.

- Minimum Height (inches): The minimum height represents the lowest point at which the floor jack can be positioned to start lifting. It is essential to ensure that the minimum height is sufficient to fit under your vehicle or object.

- Maximum Height (inches): The maximum height indicates the highest point the floor jack can reach when fully extended. Consider the maximum height to ensure it meets your lifting requirements, such as accessing different parts of your vehicle or achieving the desired height.

- Weight (lbs): The weight of the floor jack is important for portability and ease of use. A lighter floor jack can be more convenient to carry and maneuver, especially if you need to transport it frequently.

- Handle Length (inches): The handle length affects the leverage and ease of operation. A longer handle allows for more leverage, making it easier to lift heavy loads with less effort.

This table does not compare specific brands, products, or models. It focuses solely on the indicators to consider when choosing an aluminum floor jack.

| Indicator | Range |

|---|---|

| Lifting Capacity (lbs) | 3500 – 7000 |

| Minimum Height (inches) | 3 – 4 |

| Maximum Height (inches) | 17 – 20 |

| Weight (lbs) | 35 – 50 |

| Handle Length (inches) | 40 – 50 |

In the above table, the “Range” column represents the general range of values for each indicator. These ranges are provided to give you an idea of the typical variation in these indicators when choosing an aluminum floor jack. The actual values can vary depending on the specific floor jack models available in the market. Please refer to product specifications for accurate information when making a purchase decision.

FAQ

Who makes the best aluminum floor jack?

There are a few manufacturers that stand out when it comes to aluminum floor jacks. Arcan, Alltrade, and Torin are all well-known brands that produce high-quality products.

When it comes to choosing the best aluminum floor jack, it depends on your needs and budget. If you need a heavy-duty jack for professional use, then Arcan is a great option. However, if you’re looking for a more affordable option, then Alltrade or Torin would be better choices.

In general, aluminum floor jacks are more expensive than their steel counterparts. However, they offer several advantages in terms of weight and durability. If you need a durable and lightweight jack for occasional use, then an aluminum floor jack would be a good investment.

Which is better – steel or aluminum floor jack?

There is no definitive answer to this question. It depends on your needs and budget. Steel floor jacks are generally more affordable than aluminum jacks, but they’re also heavier. If you need a heavy-duty jack for professional use, then a steel floor jack would be a better choice. However, if you’re looking for a more lightweight and portable option, then an aluminum jack would be the better choice.

Where do you put a floor jack under a car?

The best place to put a floor jack under a car is on the frame. However, if you’re jacking up a smaller car, you may be able to get away with putting the jack on the body. Just be careful not to damage the car’s paint job.

Another option is to use jack stands. Jack stands provide extra support and stability when lifting a car, and they can be placed under the car in addition to or instead of a floor jack.

When using a floor jack, always make sure that the area around the jack is clear of debris. This will help prevent the jack from slipping and potentially damaging your car.

Never get under a car that is supported only by a floor jack. Always use jack stands for extra stability and safety.

How do you jack up a car with a floor jack?

First, park the car on level ground and set the parking brake. Then, locate the jack points on your car. These are usually located near the corners of the frame.

Once you’ve found the jack points, place the floor jack under the car and position it so that the lifting pad is in contact with the frame. Slowly pump the handle to raise the car off of the ground.

Stop pumping when the car is high enough for you to insert jack stands under the vehicle. Once you have placed jack stands under all four corners of the vehicle, lower the car onto them before getting underneath.

How long will my aluminum floor jack last?

With proper care and maintenance, an aluminum floor jack can last for many years. However, it’s important to inspect the jack regularly for any signs of wear or damage.

If you use your floor jack frequently, then it’s a good idea to inspect it after each use. Check for any cracks or breaks in the metal, and make sure that all of the moving parts are working properly.

It’s also a good idea to lubricate the jack periodically with WD-40 or another lubricant. This will help keep the moving parts working smoothly and prevent rust from building up on the jack.

When not in use, store your aluminum floor jack in a dry place out of direct sunlight. This will help prevent corrosion and extend its lifespan.

How much does a 3-ton aluminum floor jack weigh?

A typical aluminum floor jack weighs between 13 kg and 18 kg. A heavy-duty jack can weigh up to 23 kg. When choosing a floor jack, it’s important to consider the weight of the vehicle you’ll be lifting. A lightweight jack may not be able to lift a heavier car, while a heavy-duty jack may be too difficult to maneuver for a smaller car.

What are the best floor jacks for trucks?

The best floor jacks for trucks are typically heavy-duty jacks that can lift up to three tons. These jacks are designed to handle the weight of a truck, and they usually have a wider lifting pad to distribute the weight evenly.

When choosing a floor jack for your truck, it’s important to consider the size and weight of your vehicle. A smaller jack may not be able to lift a heavy truck, while a larger jack may be difficult to maneuver around a smaller truck. It’s also important to choose a jack that is durable and easy to use. A heavy-duty steel floor jack would be a good choice for most trucks.

Can a 2-ton jack lift a 3-ton car?

No, a two-ton jack cannot lift a three-ton car. A two-ton jack is only rated to lift up to two tons, and a three-ton car weighs more than that. If you try to lift a three-ton car with a two-ton jack, the jack could break or slip, which could damage your car or cause injury.

Is a low-profile floor jack better?

Low-profile floor jacks are designed for use with low-clearance vehicles. They have a shorter lifting pad that allows them to fit under the car without raising it too high off the ground.

Low-profile floor jacks are not necessarily better than standard floor jacks, but they may be more convenient to use with certain types of cars. If you have a low-clearance vehicle, then a low-profile jack would be a good choice. Otherwise, a standard floor jack would probably suffice.

Do I need 2 or 4 jack stands?

You will need two jack stands to support the car while you work underneath it. If you only have one jack stand, the car could fall and injure you. It’s also a good idea to have two jack stands in case one fails. If you’re working on a particularly heavy vehicle, you may want to use four jack stands for added safety.

Can I leave my car on a jack overnight?

No, you should not leave your car on a jack overnight. The car could shift or settle, and the jack might not be able to support the weight of the car for an extended period. If you need to leave your car lifted for a long period, use jack stands instead of a jack.

Can you jack up a car by the differential?

No, you should not jack up a car by the differential. The differential is a delicate component, and jacking up the car by this part could damage it. It’s also difficult to access the differential on most cars, so it’s usually not worth the effort. If you need to lift your car to work on the underside, jack it up by the frame or body instead of the differential.

Are aluminum floor jacks as strong as steel floor jacks?

While aluminum floor jacks are generally lighter than steel floor jacks, they are still engineered to be strong and durable. High-quality aluminum floor jacks can have comparable lifting capacities to steel floor jacks, making them suitable for a wide range of vehicles.

What are the advantages of using an aluminum floor jack?

Aluminum floor jacks offer several advantages over their steel counterparts. Firstly, they are significantly lighter, making them easier to maneuver and transport. Additionally, aluminum jacks are resistant to rust and corrosion, ensuring their longevity. Moreover, they are less likely to damage the vehicle’s frame or undercarriage due to their softer contact pads.

Are aluminum floor jacks suitable for heavy-duty applications?

While aluminum floor jacks are generally designed for lighter to medium-duty applications, there are heavy-duty models available on the market. These heavy-duty aluminum jacks are built with reinforced frames and larger lifting capacities, allowing them to handle heavier vehicles or equipment.

What safety features should I look for in an aluminum floor jack?

When choosing an aluminum floor jack, it’s important to prioritize safety features. Look for jacks that have a built-in overload protection system, which prevents them from being overloaded and potentially failing. Additionally, consider jacks with a dual-pump piston mechanism for quicker lifting and a bypass valve to prevent overextension.

Can I use an aluminum floor jack on all vehicle types?

Aluminum floor jacks are suitable for most vehicles, including sedans, SUVs, and light trucks. However, it’s essential to check the lifting capacity of the jack and ensure it meets or exceeds the weight of your vehicle. Some heavy-duty trucks or larger vehicles may require a higher lifting capacity than what a standard aluminum floor jack can provide.

How do I properly maintain an aluminum floor jack?

To ensure the longevity and performance of your aluminum floor jack, regular maintenance is essential. Keep the jack clean and free from debris, and lubricate the moving parts as recommended by the manufacturer. Inspect the jack for any signs of wear or damage, such as leaking hydraulic fluid or bent components, and address any issues promptly.

Can an aluminum floor jack be used for prolonged periods without issues?

While aluminum floor jacks are designed to be durable and reliable, it’s generally recommended not to leave a vehicle lifted on a floor jack for extended periods. Extended use can put strain on the jack’s components, affecting its performance and potentially compromising safety. It’s advisable to use jack stands to support the vehicle once it’s lifted with the floor jack for added stability.

What is the average lifespan of an aluminum floor jack?

The lifespan of an aluminum floor jack can vary depending on factors such as usage frequency, maintenance, and the quality of the jack itself. However, with proper care and regular maintenance, an aluminum floor jack can last for many years. Investing in a reputable brand and following the manufacturer’s guidelines for use and maintenance will help extend its lifespan.

Can an aluminum floor jack lift a vehicle with a low ground clearance?

Aluminum floor jacks are generally suitable for vehicles with low ground clearance, especially models that feature a low-profile design. These jacks have a lower starting height and can fit under vehicles with minimal ground clearance, making them ideal for sports cars, modified vehicles, or those with lowered suspensions.

Useful Video: Best Aluminum Floor Jacks

Conclusion

The Aluminum Floor Jack is a great tool to have in your arsenal whether you’re a professional mechanic or a passionate car enthusiast. It’s versatile, durable and most importantly – it’s affordable. With proper care, an aluminum floor jack can last for decades. This guide has offered everything you need to know about aluminum floor jacks, from their history and benefits to product reviews and useful tips. Use this information to make an informed decision the next time you’re in the market for a new floor jack.

References:

- https://bestfloorjacks.com/best-aluminum-floor-jack/

- https://www.forkliftaccessories.com/forkliftblog/manual-vs-powered-jacks-each-has-their-benefits

- https://www.bobvila.com/articles/best-floor-jack-for-trucks/

- https://garagespot.com/best-aluminum-floor-jacks/

- https://rxmechanic.com/how-to-bleed-a-floor-jack/

- https://www.wikihow.com/Add-Oil-to-a-Hydraulic-Jack