Have you ever wondered why steel turns blue when heated? Many of us have seen this phenomenon in action, but few people know the scientific reasoning behind it.

To understand what happens to steel when exposed to extreme temperatures, we must delve into a bit of chemistry and metallurgy!

In this article, we’ll be exploring the science behind why steel turns blue—and how understanding it can help you as an engineer or metalworker. So make sure to read on if you want to find out more about this mysterious transformation!

How Light and Color Work?

Before we get into why steel turns blue, let’s first talk about light and color. Light is made up of different wavelengths—each of these wavelengths corresponds to a particular color.

For example, shorter wavelengths are perceived as blues and greens, while longer wavelengths are seen as oranges and reds. This is why the sky appears blue during daylight—shorter wavelengths are scattered more by the atmosphere.

Thin Film Interference

Thin film interference is when light waves bounce off two surfaces. Every time the waves hit a surface, part of the wave is absorbed and the rest is reflected.

The reflected part of the wave bounces around between the two surfaces until it comes out from one side. Depending on how many times and at what angles this process occurs, different colours are produced.[1]

Steel’s Relationship to Thin Film Interference

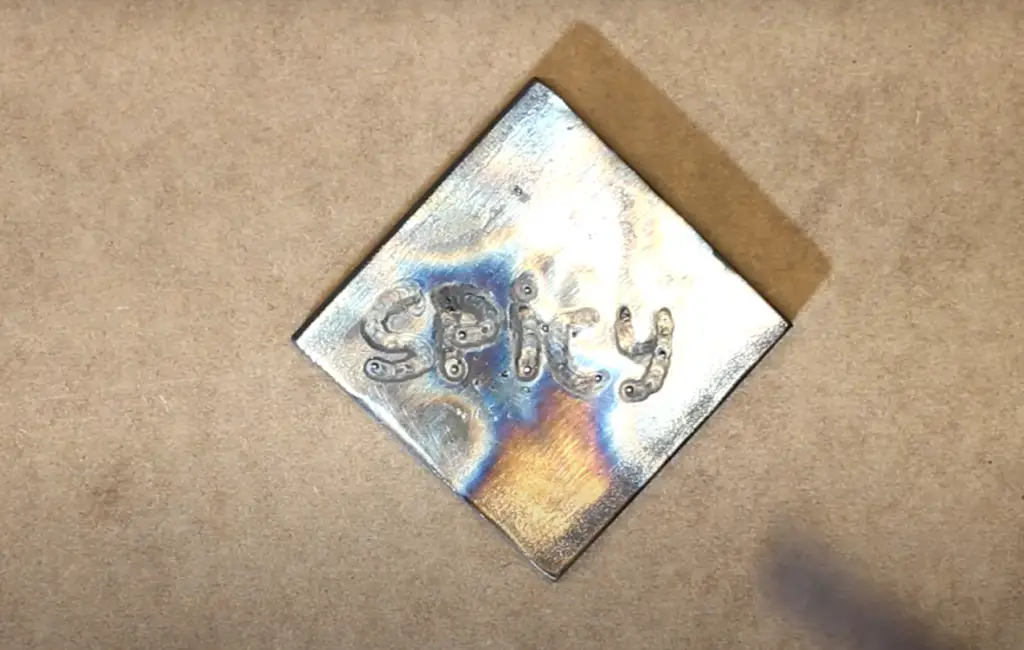

When steel is heated to a high temperature, an oxide layer begins to form on the surface of the metal. This layer becomes very thin—only a few billionths of an inch thick.

This is called “blue tempering.” It means the steel is good quality because it was heated to a high temperature. Experienced metalworkers use this method to check if their steel is good quality.

How Light Works on Metal?

When light waves hit metal, they go faster than in a vacuum. This makes the waves scatter and reflect off the metal surface in a different way. Depending on how thick or thin the layer is, different colors can be produced by the interference of light waves.

When steel is heated to a high temperature and an oxide layer forms on its surface, the interference of light waves causes the steel to turn blue.

Why Steel Coloring is So Useful?

Steel coloring is a great indicator of whether or not the steel has been heated to the right temperature.

Experienced metalworkers can use this method to check if their steel is good quality and strong enough for certain applications. It’s also a great way to tell if the heat-treating process was done correctly. [1]

What Is Heat Treatment?

Heat treatment is a process where we change the way a metal behaves. We do this by exposing it to very high or very low temperatures.

We use heat treatment for different reasons, like making the metal stronger or less likely to rust.

Why Does Steel Turn Blue When Heated?

When exposed to extreme temperatures, steel undergoes a transformation called “tempering.” This is when the metal’s internal structure changes and it becomes harder and more durable.

When steel is tempered, its molecules change how they are arranged. This makes the metal look blue when you see it because it absorbs blue and green light.

This is called the “tempering color.” It can help engineers and metalworkers see if steel has been exposed to extreme temperatures. It is also a good way of telling if the metal has been heat treated properly or not.

A Rust Resistant Finish

Rust is a type of corrosion that happens when oxygen and water combine with the metal. The heat treatment creates a thin oxide layer on the surface of steel.

This layer does not allow water or oxygen to react with the metal, so it protects it from rusting for a long time.

This makes the steel more durable and increases its lifespan. Heat treatment is also used to improve the strength of steel, making it more resistant to wear and tear. [2]

The Bluing of Steel: How is it Accomplished?

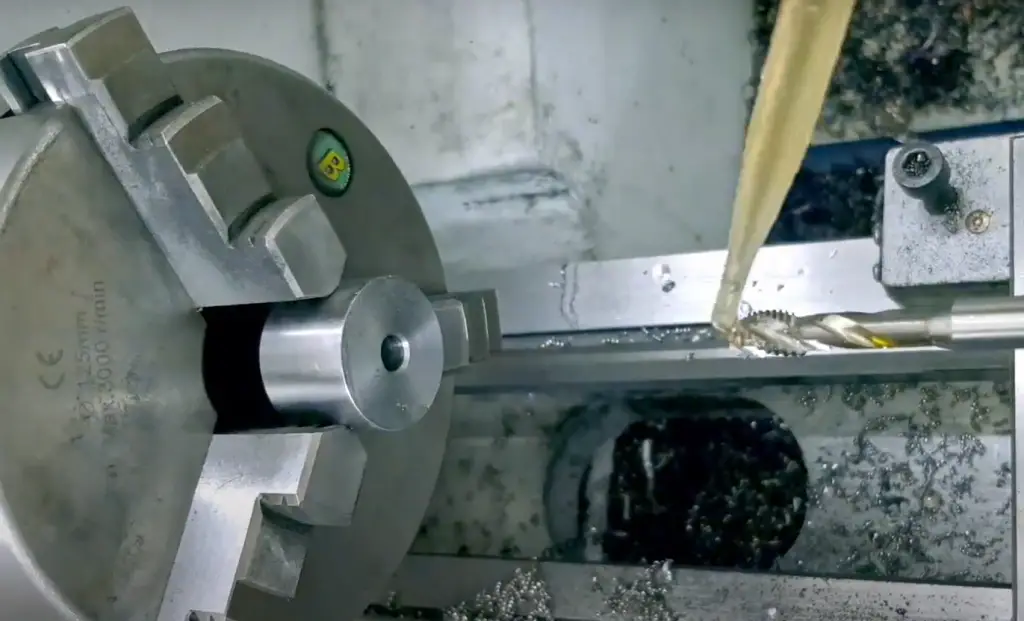

The process of bluing steel has been used for centuries. It involves heating the metal to a very high temperature and then cooling it down slowly. This creates a thin oxide layer which turns the steel blue in color.

This process can be done manually or with modern machines that use lasers and high-pressure gas jets. The use of these machines results in a more uniform, consistent finish.

Tips

While it’s possible to do the bluing of steel on your own, it is not recommended unless you are an experienced metalworker. It is a complex process that requires special tools and equipment. To avoid damaging your steel, here are some tips:

- Use gloves and safety glasses when working with heated steel.

- Make sure your workspace is well ventilated.

- Heat the steel slowly and evenly.

- Cool it down gradually and keep a steady pace.

- Follow all instructions carefully and use the correct tools for the job.

Warnings

Steel is a strong material, but it can break when exposed to extreme temperatures. If the steel is heated too quickly or cooled down too rapidly, it can become weaker and less durable. This could lead to cracks and fractures in the metal which would reduce its strength.

Follow the tips above and always read the instructions carefully before starting any project.Steel turns blue when it is heated because of the way the metal molecules change. This means that the heat-treating process is working and the steel is strong and will not rust.

With some knowledge and practice, you can make beautiful pieces of steel that will last a long time.

FAQ

What is it called when metal turns blue from heat?

The process of tempering or bluing happens when steel is exposed to extreme temperatures and the molecules rearrange. This makes the metal absorb blue and green light, which results in a blue color.

Is it dangerous to heat-treat steel?

Heating and cooling steel can be dangerous if done incorrectly. It is important to take all necessary precautions and follow the instructions carefully when heat-treating steel.

What type of steel can be blued?

Any type of steel can be blued, though some steels are better for this process than others. It’s best to consult an expert before attempting a project involving bluing steel.

Does bluing make steel stronger?

Bluing can help make steel stronger by creating a thin oxide layer on its surface. This layer makes it more resistant to rust and wear, so it increases the lifetime of the metal.

What is heat-treating used for?

Heat-treating is used to improve the strength, durability, and lifespan of steel. It can also be used to create a rust-resistant finish or give the metal a distinctive color.

Why does metal turn colors when heated?

Metal changes colors when heated because the molecules in the metal change their shape due to the high temperature.

This can cause the metal to absorb different wavelengths of light, resulting in a range of colors from blue and green to yellow and red.

What temperature does steel turn blue?

Steel can start to turn blue at temperatures as low as 204 degrees Celsius (400 degrees Fahrenheit). It may take longer for the color to become noticeable depending on the type of steel.

Overall, steel turns blue when it is heated because of a process called bluing. Bluing makes the steel more resistant to damage. To do this, you need to heat the steel to very high temperatures and then cool it down slowly.

This is part of heat treating steel and should be done by experienced metalworkers or with machines that use lasers or high-pressure gas jets.

What is it called when steel turns blue?

When steel is blue, we say it is “bluing” or “tempering.” This process changes the way the molecules are put together in the metal. The metal starts to absorb different colors of light. This makes a range of colors from blue and green to yellow and red.

Why is metal blue?

Metal bluing is used to make the steel stronger and more resistant to rust and wear. This will help extend its lifetime, as well as give it a decorative finish or distinctive color.

It is important to understand the process before attempting it, as mistakes can lead to dangerous consequences.

Is blue steel actually blue?

The color blue steel does not come from the color blue. It gets its name from a process called bluing. This process changes how the molecules are arranged in the metal particles and how they absorb light.

Because of this process, the metal will absorb different wavelengths of light. This results in a range of colors including blue, green, yellow, and red.

What happens when steel turns blue?

When steel is blued, it means that the molecules in the metal have rearranged themselves due to extreme temperatures.

This causes the metal to absorb different wavelengths of light which produces a range of colors such as blue, green, yellow, and red.

Bluing also helps make the steel stronger and more resistant to wear and rust, making it more durable.

What is the advantage of bluing steel?

The advantage of bluing steel is that it helps make the metal stronger and more resistant to rust and wear. This can help extend its life, as well as give it a decorative finish or distinctive color.

It also makes it look better, which can be beneficial if you are making objects with steel for aesthetic purposes.

How do you make blue steel?

Heating steel to high temperatures and then cooling it down slowly is called bluing. This process is known as heat-treating and should be done by an experienced metalworker or with machines such as lasers or high-pressure gas jets.

It’s important to understand the process before attempting bluing, as mistakes can lead to dangerous consequences.

The process of bluing steel requires skill and knowledge. If you want to try it, get the proper training and safety equipment before you start. With the right knowledge, you can create something beautiful with blue steel for years to come.

Why is blue steel so popular?

Blue steel is popular because of the beautiful color and its durability. This makes it a great choice for decorative pieces and projects that require a strong material.

The process of bluing also helps make the steel stronger and more resistant to rust and wear, which can help extend its life.

Why does steel turn blue when heated?

Steel turns blue when it is heated because of a process called bluing. This makes the steel more resistant to damage by rearranging the molecules in the metal and changing how they absorb light. Bluing also helps make the steel stronger and more resistant to rust and wear.

It takes very high temperatures, such as those from lasers or high-pressure gas jets, to do this process correctly.

Steel bluing is an important process for metalworkers and should only be done by experienced individuals who know the proper safety procedures.

Does bluing make steel stronger?

Yes, bluing does make steel stronger. This is because it changes the way the molecules are arranged in the metal. This makes the metal more resistant to rust and wear.

Bluing also changes how the metal absorbs light, which is what gives it its distinctive color. Only trained professionals should do bluing, or it can be done with machines such as lasers or high-pressure gas jets.

Bluing is a process that helps make steel stronger and more resistant to wear and rust. It also gives steel a decorative finish or distinctive color. This can help extend the life of the steel. If you want to try this process, get proper training and safety equipment before you start.

Do different colors of steel mean different temperatures were used?

Yes, different colors of steel can indicate different temperatures were used. This is because the bluing process changes how light is absorbed by the metal.

Different temperatures will produce different colors such as blue, green, yellow, and red. It takes very high temperatures to properly do this process, so it should only be done by experienced professionals.

Does bluing reduce corrosion of steel?

Yes, bluing can help reduce corrosion of steel. This is because it helps rearrange the molecules in the metal and change how they absorb light. This makes the steel more resistant to rust and wear.

The process of bluing also strengthens the steel, making it more durable and less likely to corrode over time. If you are interested in bluing, make sure you get the proper training and safety equipment before attempting it.

Can bluing steel be done at home?

You should not try to use blue steel at home. Only experienced professionals or machines such as lasers or high-pressure gas jets should do this. If you do it wrong, it could be dangerous. If you want to use blue steel, get the proper training and safety equipment first.

When you blue steel, it makes the steel stronger and less likely to rust or break. It also gives the steel a shiny, pretty finish that will last for a long time. If you do it right, bluing can help keep steel parts working for longer.

Can bluing be used on other metals?

Bluing can also be used on metals such as brass and copper. This is because the process of bluing changes how the molecules in the metal absorb light. The same high temperatures that are required for bluing steel are needed to do this process on other metals.

It should only be done by experienced professionals or with machines such as lasers or high-pressure gas jets.

The process of bluing makes metals stronger. It also makes the metal not get rust and not wear out as easily. Different colors of steel mean different temperatures were used when the metal was being blued.

You should only let someone who is experienced and has the right training do this process. They should also have the right safety equipment.

Useful Video: Bluing steel with heat [different colors from gold to purple to blue]

Conclusion

Knowing why steel turns blue when heated can help you avoid accidents and dangerous situations. By understanding the science behind this phenomenon, you can also appreciate the beauty of it.

The next time you see a piece of steel that has been heated, take a moment to think about the chemistry and physics that are at work.

References:

- https://makeitfrommetal.com/why-does-steel-turn-blue-when-heated/

- https://alphadetroit.com.au/bluing-of-steel-by-heat-treatment-why-and-how-it-happens/