If you are new to machining, it can be confusing to learn about all the different types of tools and terms. What is a Bridgeport mill? It is something that every machinist should know about.

Well, if you’ve been asking those very same questions yourself, then this blog post is just for you!

In this article we’ll cover everything from what a Bridgeport mill is and why they’re used by machinists to how their design has changed over time. Let’s get started!

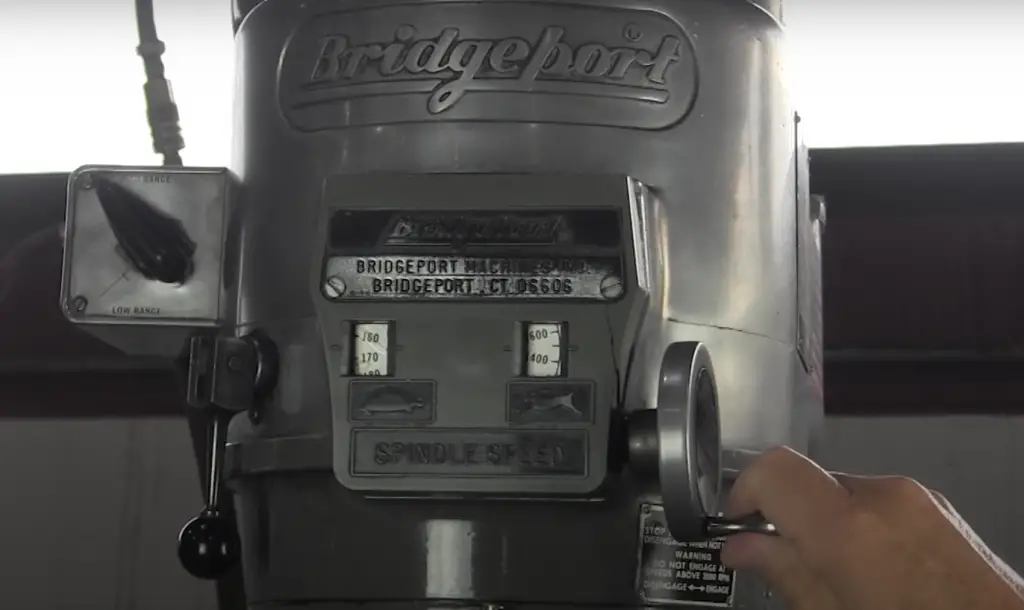

Bridgeport Series I Standard Mill

A Bridgeport Series I Standard Mill is a machine that has been used by machinists for many years. It helps to make precision parts for things like aircraft engines and automobiles. The machine has a base, table, spindle, head assembly, saddle, and quill.

The Bridgeport mill was introduced in the 1930s. Since then, it has changed a lot to keep up with modern technology. Some of these changes include a new motor, better electrical components, and the ability to add power feed.

With its adjustable head assembly, powerful motor, and precise movements along all three axes, the Bridgeport mill makes it easy for machinists to get their job done. [2]The Ram

The ram type milling machine is a popular and widely used milling machine. Unlike the Bridgeport, it has a movable head that can be moved in different directions. This feature allows for more complex shapes to be machined than on the Bridgeport.

The ram type milling machine has a spindle and feed mechanism built in. This helps the machine work better than the Bridgeport. The ram type milling machine can also hold bigger parts because it has a larger table size.

The ram type milling machine is great for intricate designs such as die-casting dies,as well as complex shapes like turbine blades. The head can be moved in different directions which allows for more complex shapes to be machined.

The ram type milling machine is a good tool for making intricate and complex parts. It can make larger parts than the Bridgeport because of its larger table size. And because its head is movable, it can make more complex shapes too.

The Turret

The turret type milling machine has a rotating table. This means that it can be moved in multiple directions. This is good because it allows for multiple tools to be used at the same time.

It also cuts down on the amount of time it takes to get ready. The head is fixed and does not move like the Bridgeport or ram type machines.

The turret milling machine is useful for making complex parts quickly and accurately. It is ideal for production work, as it can hold multiple tools and change them quickly. It is also good for machining large parts because of its large table size.

Rigidity

It is important for milling machines to be rigid. This means that the parts will not move around while they are being machined.

The Bridgeport, ram type, and turret machines all have good rigidity because they are made with heavy cast iron frames. This results in more accurate parts. [2]

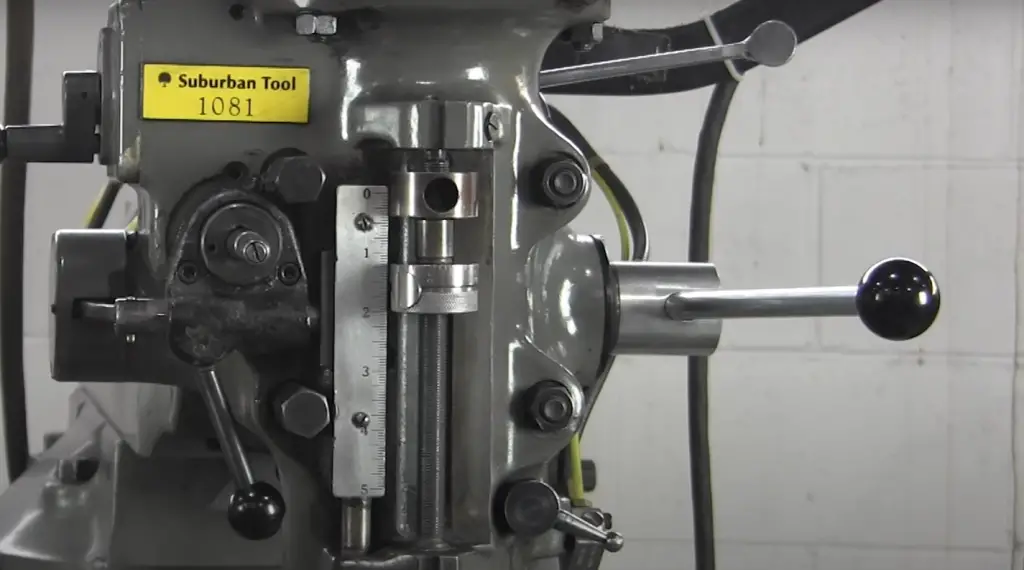

The Quill

The quill is a part of the milling machine. It helps move the spindle and controls how deep the cut is. Bridgeport and ram type machines have adjustable quills. Turret type machines have fixed quills.

The quill is an important part of any milling machine because it allows for precise cutting. It helps to control and adjust the depth of cut, which can be useful for machining intricate parts.

Overall, the Bridgeport, ram type, and turret milling machines are all excellent tools for making precise parts quickly and accurately. Each has its own advantages depending on what you need it for.

The quill is an important part of all these machines and helps to ensure accuracy when machining parts. Knowing the different types of milling machines can help you choose the right one for your needs.

The Background of Bridgeport Milling Machine

The Bridgeport milling machine was developed in the 1930s by a company called the Bridgeport Machine Tool Company. The name ‘Bridgeport’ comes from its home town of Bridgeport, Connecticut.

At the time, it was revolutionary because it significantly reduced set-up times and made production more efficient. It was also much more affordable than other machines at the time.

The Bridgeport milling machine is still used a lot today in manufacturing and engineering. People like it because it is very strong and accurate, and it can be used for different things.

Bridgeport can make small, precise parts or work on big projects like bridges or buildings. With its strong construction, powerful motor, and precise movements along all three axes, the Bridgeport is a versatile tool for any workshop. [1]

What Is Bridgeport Milling Machine?

The Bridgeport milling machine is a heavy-duty tool used for precision machining. It has a rotating spindle head that moves along the X, Y, and Z axes. This allows it to make precise cuts with different shapes and sizes of tools.

The Bridgeport is one of the most popular types of milling machines because it is accurate, reliable, and versatile. It can be used for a variety of tasks from drilling to milling to turning.

Bridgeport Milling Machine Parts

The Bridgeport milling machine is made up of several parts. The most important components are the spindle, table, head, and quill.

The spindle is the part that moves along the X, Y, and Z axes. It is powered by a motor. The table is responsible for holding the material to be machined. It is a flat, rectangular surface that moves along the X and Y axes.

The head is attached to the spindle and has tools like drills and cutters mounted on it. The quill is a part of the head which helps control how deep the cuts are made.

There are different parts to the machine that help it make accurate and precise cuts.

What Accessories With the Vertical Milling Machine?

The vertical milling machine comes with a few accessories. These accessories can be used to increase productivity, accuracy, and speed.

The most common accessory for the mill is the power feed table. This device attaches to the side of the mill and provides a steady movement for heavier cuts. It also helps position parts more accurately.

Another common accessory is a dividing head. This attachment is used to divide work pieces into equal parts. It makes it easier to produce multiple copies of the same part or cut complicated shapes and gear teeth.

Other accessories include rotary tables, digital readouts, quill stops, and collets. All these devices can be used to make complex machining operations easier and more accurate.

Benefits of Using a Bridgeport Milling Machine

The Bridgeport milling machine is an excellent tool for precision machining. It provides high accuracy and repeatability, making it ideal for production work.

The Bridgeport can also be used for a variety of tasks from drilling to milling to turning. This makes it very versatile and useful in a wide range of applications. It is also a very strong and reliable tool, so you can be sure that it will perform well for many years.

The Bridgeport milling machine is a good choice for anyone who wants to do precision machining. It has solid construction, precise movements along all three axes, and robust motor power.

All of these features make it a good choice for a lot of different projects. With proper maintenance and care, Bridgeport will work well in your shop for many years.

Bridgeport Series 2

The Bridgeport Series 2 is a popular model of the Bridgeport milling machine. This version has a number of features that makes it stand out from other models.

The main difference between the Bridgeport Series 2 and other models is the head configuration. The series 2 has a square ram-style head that can be adjusted to different angles. This makes it easier to move the tools around and get into tight corners.

The series 2 has a larger quill than other models, which allows for more precision when making vertical cuts.

This gives you more control over how fast or slow the machine operates.Bridgeport-Type Machines

The Bridgeport-type machine is the most popular milling machine design in use today. These machines are based on the original Bridgeport design and have been used for decades.

Bridgeport-type machines are very versatile and can be used for different tasks like drilling, milling, and turning. They are also accurate and have solid construction, making them great for precision machining.

Bridgeport-type machines are popular in many countries, not just the United States. They are used in different types of businesses and can be found in small and large job shops and production facilities. With good care and maintenance, they will continue to work well for a long time.

Milling Heads

The Bridgeport milling machine has a number of different heads that are used to perform different types of machining operations.

The standard vertical head is the most common type and provides three-axis movement for drilling, milling, and turning. This head can be cut horizontally or vertically, depending on the workpiece orientation.

Bridgeport Today

The Bridgeport milling machine is a type of machine that people use today. It is popular because it is accurate and has a lot of features. Machinists like this machine because it is precise.

Many modifications have been made to the original design over the years, but it remains true to its roots. It is still the most popular type of milling machine in use today.

The Bridgeport milling machine is a great tool for precision machining. It has been used by people all over the world for many years and with proper care, it will continue to be an essential piece of machinery in many shops.

FAQ

What is Bridgeport Mill?

The Bridgeport milling machine is a popular type of machine that is used for making things very accurately.

It uses a ram-style head to move the tools around, and features three axes of movement for drilling, milling, and turning operations.

What can you do with a Bridgeport Mill?

A Bridgeport milling machine can be used for drilling, milling, and turning operations. It is highly versatile, so it can handle a wide variety of tasks.

What is the difference between a Bridgeport Series 2 and other models?

The Bridgeport Series 2 has a square ram-style head that can be adjusted to different angles. This means that it is more versatile and easier to use for precision operations.

It also has adjustable spindle speed from 120-4300 RPM, which means that you can control how fast or slow the drill is spinning.

What type of head is used on the Bridgeport Mill?

The standard vertical head is the most common type used on the Bridgeport mill. It provides three-axis movement for drilling, milling, and turning operations and can cut horizontally or vertically depending on the workpiece orientation.

How long have Bridgeport Mills been around?

The original Bridgeport design for milling machines has been around since the 1930s and is still being used today because it is versatile and has a lot of features. If you take care of it, it can last for many years.

Where are Bridgeport Mills used?

Bridgeport mills are found in many countries around the world, including the United States. They are used by businesses of all sizes and are popular in job shops and production facilities.

What is the best way to maintain a Bridgeport Mill?

It is important to do regular maintenance on your Bridgeport mill. This means changing the oil regularly, inspecting the parts for damage or wear, and making sure all of the external parts are kept clean and lubricated.

Additionally, it’s important to make sure that all of the parts are properly tightened and adjusted.

Why are Bridgeport Mills so popular?

Bridgeport mills are popular because they are accurate and reliable. They can be used for a variety of tasks, and with proper care, they will last a long time. Additionally, they are relatively affordable and easy to find parts for.

Is Bridgeport a good milling machine?

Yes, Bridgeport milling machines are good for many different tasks. They are accurate and reliable, making them great for precision machining operations.

Additionally, they have lots of features that make them easy to use and keep in good condition, which is why so many people still use this classic design.

How do I identify a Bridgeport mill?

Bridgeport mills often have a “rounded ram” design, which is a head that is square-shaped with rounded corners. This head can be adjusted to different angles.

Additionally, the Bridgeport logo may be on the front of the machine. You might find Bridgeports in catalogues or online. They might have numbers that can help you identify them.

What are some safety tips for using a Bridgeport Mill?

When using a Bridgeport mill, you must wear the right safety gear, like eye and ear protection. Also, make sure the machine is grounded properly. Never try to fix or change the machine unless you know how and have been trained to do so.

Keep all moving parts away from your clothes, skin, and hair. Lastly, always follow the manufacturer’s instructions for using and taking care of the machine.

Why is it called Bridgeport?

Bridgeport machines are named after the town of Bridgeport, Connecticut. This is where the company started making the machines. The company became very good at making precision machining tools, especially milling machines. Even now, people still want to buy Bridgeport machines because they are accurate and reliable.

The Bridgeport Mill is an important tool for machinists and anyone who needs to do precision work. It is versatile, reliable, and easy to use. With proper maintenance and care, it can last for many years.

Are Bridgeport Mills still made?

Yes, Bridgeport Mills are still being made today. They are manufactured by Hardinge Inc., who acquired the original Bridgeport company in 2001.

The machines they make have been improved and updated over the years to keep up with current industry standards, but the classic design remains popular among machinists.

How can I find a used Bridgeport Mill?

Used Bridgeport Mills can be found online or in machining and industrial equipment catalogues. There are also companies that specialise in buying, selling, and restoring vintage machines, such as Bridgeport Mills.

If you are looking for a good deal on a used one, it is worth searching the web or asking around at local machine shops.

Useful Video: How to use a Bridgeport and its features!

Conclusion

If you’re in the market for a Bridgeport Mill, or if you’re just curious about how they work, hopefully this article has given you a good overview.

These machines are essential for many manufacturing and production operations, so it’s important to have a general understanding of them.

As always, if you have any further questions or would like more information, don’t hesitate to reach out to us. We’d be happy to help!

References:

- https://www.market-prospects.com/articles/bridgeport-milling-machine

- https://makeitfrommetal.com/whats-a-bridgeport-mill-the-beginners-guide/