Anodizing aluminum is a process where you use electricity to protect the aluminum from rusting. This also makes the aluminum more appealing and resistant to wear and tear. Some people think this is too complex to do on their own, but it is actually not as difficult as it may seem!

In this blog post, we’ll dive into the basics of how to anodize aluminum at home and answer some common questions along the way. Read on to learn more!

What Does Anodizing Aluminum Do?

Anodizing aluminum is a process used to protect and strengthen the aluminum. This is done by growing an oxide layer. The surface hardness increases, which means it reduces wear resistance.

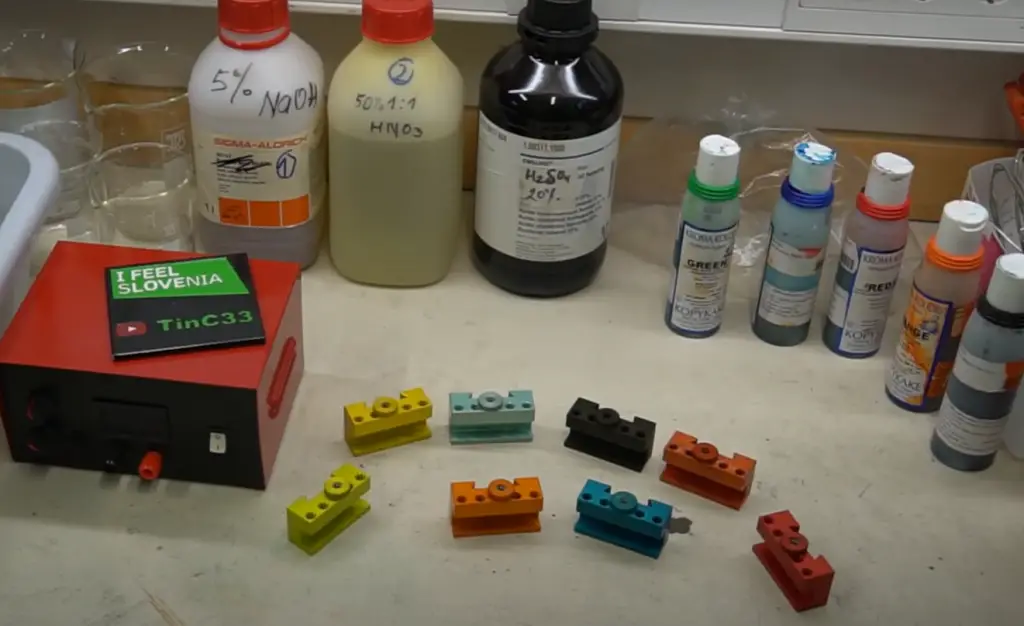

Anodized aluminum also looks more appealing as it takes on colors such as black, blue, green, bronze and many others. In addition to this, anodizing aluminum prevents corrosion and makes it highly resistant to extreme temperatures.

What You Need

Anodizing aluminum means that you need a few things. The most important thing you need is an electrolyte solution. This can be a sulfuric acid bath or a boric acid bath. You can find this at your local hardware store.

In addition to this, you’ll need some electrical current, which is usually supplied by a battery charger or an automotive starter.

You will need a piece of aluminum. It can be any size. It just needs to fit in the container you will use for the electrolyte solution. You will also need rubber gloves, safety glasses, and other protective clothing before you start. [1]

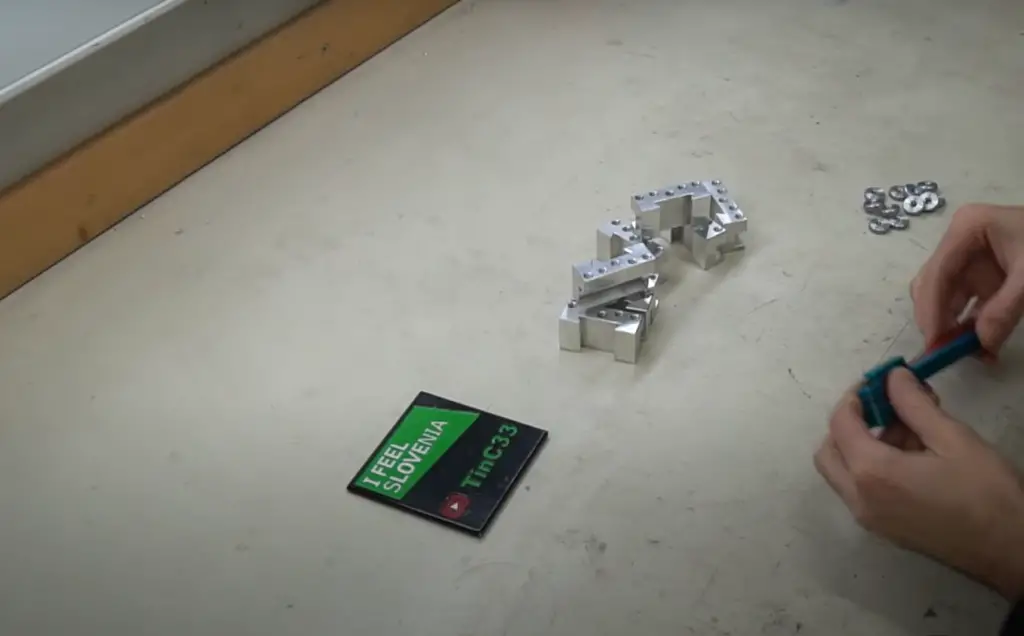

Small-Scale Anodizing Setup

Power Source

Start by finding a suitable power source. You can use a car battery charger or an automotive starter.

This should be enough for small-scale work and will save you money compared to buying higher-voltage supplies.

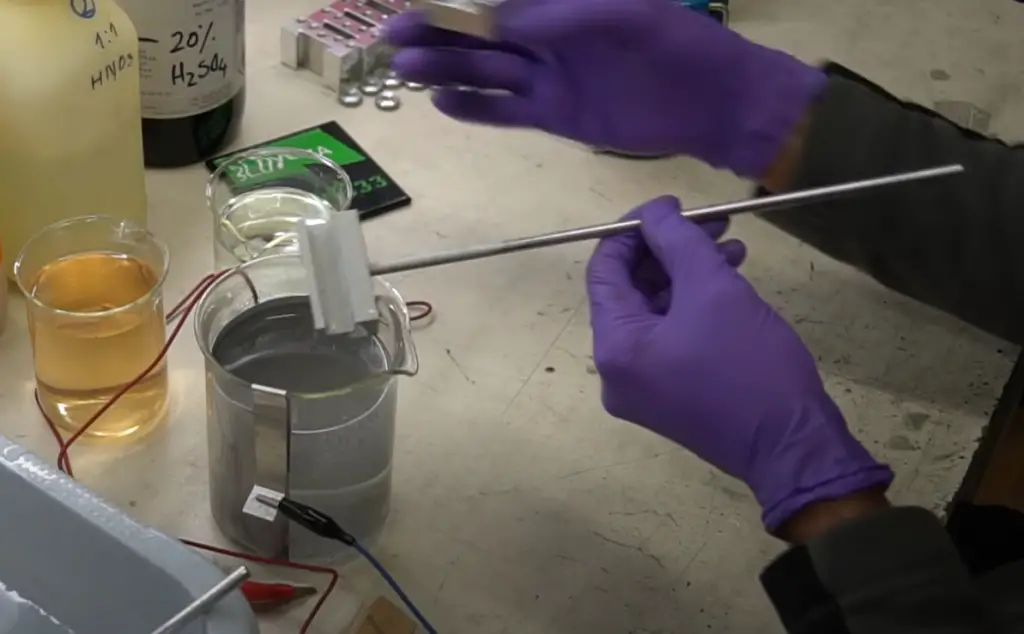

Acid

After you find a power source, you can get ready for the acid bath. You will need to mix one part sulfuric acid with three parts distilled water in a container.

Make sure that the container won’t have a bad reaction with the acid and that your work area has good airflow.

Dye

The next step is to add dye to the acid. This will give your anodized aluminum a colour. You can find dyes in different colors at auto parts stores and hardware stores. Make sure you use a non-toxic, food-grade dye that won’t react with the acid.

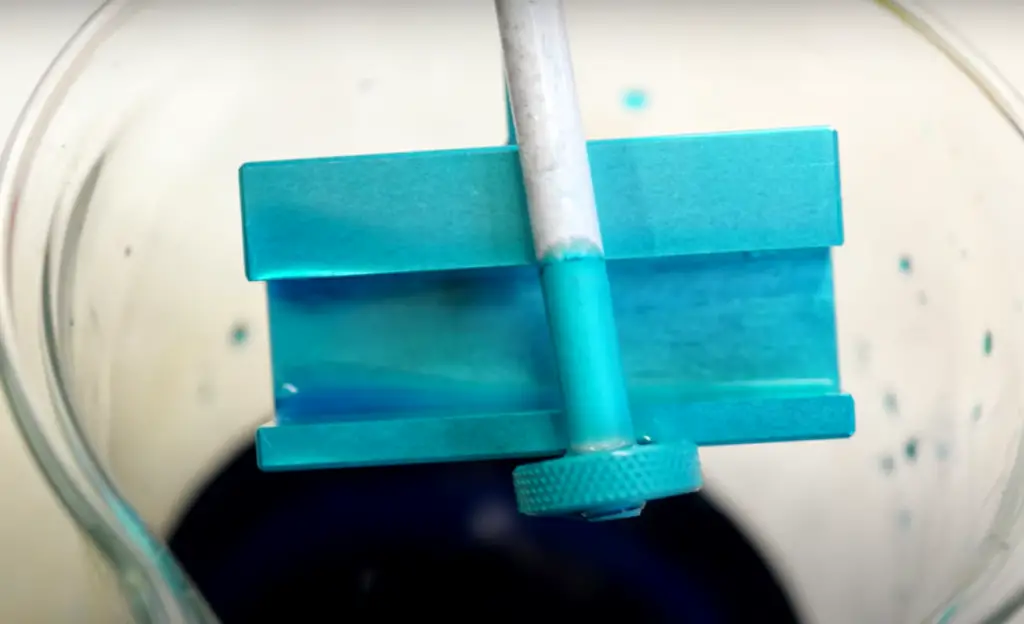

Cathode

The cathode is the negative part of your anodizing setup.

This can be made from a piece of scrap metal that has been cleaned of all oil and dirt. You will attach this to the negative terminal of your power source.

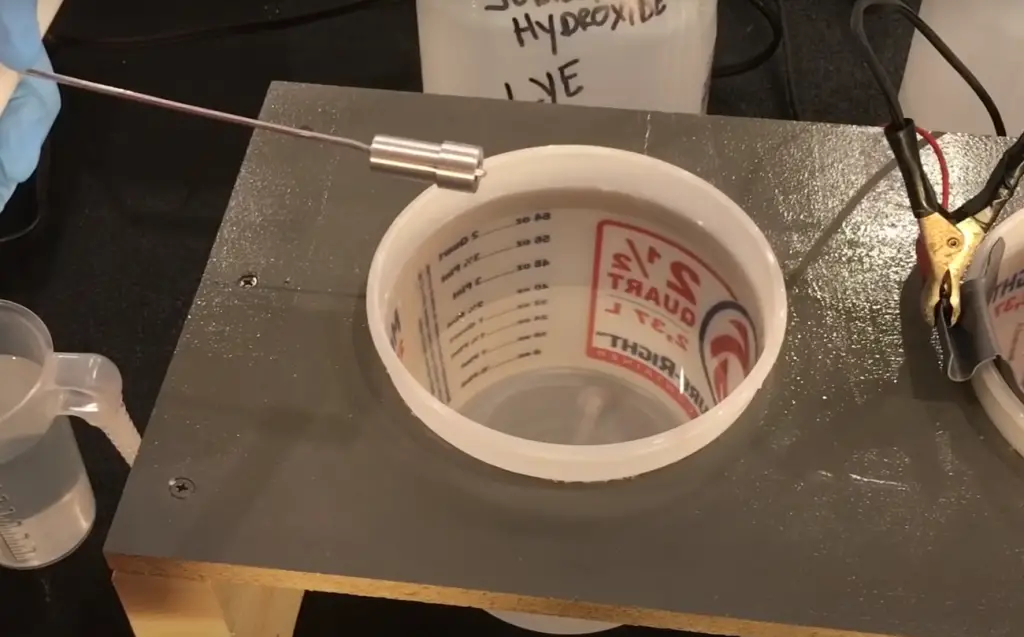

Container

You will need a container that is large enough to hold your piece of aluminum and the acid solution.

Wire Racking

The wire racks will help you suspend the aluminum piece in the container. This will ensure that it doesn’t touch the cathode and is evenly suspended in the solution.

Degreaser

Before you anodize, it’s important to clean the aluminum piece. You can do this by using a degreaser or by boiling it in a solution of water and baking soda. This will help to remove any oils and dirt from the surface.

Acid Neutralizer

Once the piece has been anodized, you will need to neutralise the acid. This can be done with a baking soda solution or an ammonia solution.

Agitator

An agitator can be used to stir the acid solution and make sure that the aluminum piece is evenly exposed to the electricity. This will ensure even anodizing.

Safety Gear

Make sure to put on gloves, glasses and other clothes that will protect you before you start the anodizing process. This will help keep you safe from getting hurt by electricity or chemicals.

Miscellaneous Handy Stuff

You may also need some extra items like a thermometer to measure the acid temperature, some pliers to hold pieces of metal and a small brush for scrubbing the aluminum piece.

Once you have all your materials together, you are ready to start anodizing your aluminum piece. Make sure to follow the instructions carefully and stay safe!

How to Anodize Aluminum the DIY Way

Scotch-Brite the Aluminium

Start by scotch-briting the aluminum piece. This removes any oils and dirt from the surface. Once you have done this, rinse it off with water and let it dry.

Don the Gear

Put on rubber gloves, safety glasses and other protective clothing.

Clean the Parts

Clean the power source, cathode and container thoroughly to remove any oils or dirt that could interfere with the anodizing process.

Etch the Parts

You can etch the aluminum piece in an ammonia solution to further clean it. This will help give a better finish to your anodized aluminum.

Cleanliness Check

Make sure everything is clean before you start the anodizing process.

Rack the Parts

Position the aluminum piece and cathode on the wire racks in the container. Make sure they don’t touch each other.

Pour the Bath

Pour the acid/dye mixture into the container. Make sure it goes around your aluminum piece and cathode.

Set up the Gear

Attach the positive terminal of your power source to the aluminum piece and the negative terminal to the cathode.

Add Power

Turn on the power source and adjust it to the desired voltage.

Heat Up the Dye

If you’re using a heated dye, make sure to turn on the heating element.

Get your Baths Ready

You may need to have a few baths ready for rinsing and neutralising the aluminum piece.

Monitor the Process

Keep an eye on the process and be prepared to turn off the power if needed.

Part Dunking

Once the aluminum has been anodized, dunk it in a cold water bath to stop the process.

Neutralise the Baths

Clean up all of your baths with a baking soda or ammonia solution.

Make sure to dispose of any used acids or dyes properly.

Sealing

Seal the anodized aluminum piece with a clear coat or wax. This will help protect it from wear and tear.

Inspection Time

Finally, inspect the aluminum piece for any imperfections or discoloration. If everything looks good, you have successfully anodized your aluminum piece!

Anodizing aluminum is a process where you can create beautiful pieces of aluminum. You need the right materials and safety gear to do it. Remember to stay safe and follow the instructions carefully.

Warning & Precautions

Anodizing aluminum is an electrical process and it is very dangerous. You need to be careful and follow all of the safety instructions. This includes wearing the right clothes and keeping any materials that can catch on fire away from the work area. You also need to get rid of any acids or dyes you use in a safe way.

Always consult a professional if you feel like you don’t know what you are doing or if something doesn’t feel right. Doing it yourself can be a great experience, but safety always comes first!

Extra Tips

- Make sure to use distilled water for all of your baths.

- You can use a mild detergent or soap to clean the aluminum piece before you start anodizing it.

Anodized aluminum should not be used with other metals in contact with each other as this could cause corrosion. - Make sure to inspect your aluminum piece after anodizing and before sealing it.

- You can also use a coloured dye to give your aluminum piece a unique look.

With the right materials, safety gear and instructions, you can successfully anodize your aluminum at home.

Take the time to prepare and stay safe while doing it!

FAQ

Can you anodize aluminum at home?

Yes, you can anodize aluminum at home with some special materials and safety equipment. Make sure to follow the instructions carefully and stay safe.

What do I need to anodize aluminum?

You will need a power source, acid solution, cathode, container and other items like thermometers or brushes. You will also need safety gear like gloves and glasses.

Is anodizing aluminum dangerous?

Yes, it can be dangerous if you don’t take the necessary precautions. Make sure to wear protective clothing and follow the instructions carefully.

What is the process for anodizing aluminum?

The main steps are:

- Scrubbing the aluminum with a special tool

- Putting on safety gear like a mask

- Cleaning the parts you want to colour

- Using acid to help the colour stick better

- Putting the piece in a power source like batteries

- Filling up a container with the colouring liquid

- Heating up the liquid if needed

- Dunking it in a cold water bath

- Finally seal your piece with a clear coat or wax

How long does anodizing aluminum take?

This process usually takes around an hour, depending on the size of your aluminum piece and the type of bath you’re using.

Can I use other metals for anodizing?

Yes, you can use a variety of metals for anodizing. However, aluminum is the most commonly used metal for this process.

What can I use to anodize aluminum?

You can use dyes, acid solutions and other compounds to anodize aluminum. Make sure to research the specific type of compound you’re using before starting the process.

Is it hard to anodize aluminum?

Anodizing aluminum is not necessarily difficult, however it does require certain materials and skills.

Make sure to read up on the process and use the necessary safety gear before you start.

Can you anodize aluminum without electricity?

No, anodizing aluminum requires electricity. This is why you need a power source such as batteries or a generator.

What is the 720 rule for anodizing?

The 720 rule is a safety measure that states that you should not expose the aluminum to more than 720 volts per square inch when anodizing. This will ensure that your aluminum piece stays safe while being treated.

Can you fix mistakes with anodized aluminum?

Yes, it is possible to fix mistakes with anodized aluminum. You can use special tools to remove the anodized layer or you can try using a different color for your piece.

Is anodizing cheaper than painting?

Anodizing is generally more expensive than painting, however it is also much more durable and long-lasting. This makes it a great option for projects that require extra protection.

Can you anodize aluminum indoors?

Yes, you can anodize aluminum indoors as long as the area is well ventilated. Make sure to wear the necessary safety gear to avoid any danger or harm.

What is the best way to clean anodized aluminum?

The best way to clean anodized aluminum is by using a gentle cleaning solution. Avoid abrasive cleaners as they can damage the surface of your piece. You can also try using a special brush or cloth for more thorough cleaning.

What is the difference between anodizing and plating?

Anodizing is different from plating because anodizing creates a thicker surface. Plating only deposits a thin layer onto the aluminum.

Anodizing also offers more protection against wear and tear. Plating can also create different aesthetic effects, but anodizing is mainly used for protection.

Why is anodizing aluminum important?

Anodizing is a process that helps to protect your aluminum piece from corrosion and wear. It also makes the surface more durable, which can help increase its lifespan. Anodizing also increases aesthetic effects, making it a great option for projects that require extra protection or color.

How do I make sure my anodized aluminum is safe?

It is important to make sure your anodized aluminum is properly sealed when you are finished. You can use a clear coat or wax to seal it and protect it from wear and tear.

Additionally, make sure to read up on safety instructions before beginning the process, such as the 720 rule. This will ensure that your aluminum piece stays safe while being treated.

Finally, make sure to inspect your finished product for any signs of damage or corrosion before using it. This will help you keep your anodized aluminum safe and looking great for a long time.

How do I maintain my anodized aluminum?

To keep your anodized aluminum looking its best, make sure to clean it regularly with a mild detergent. Avoid using abrasive cleaners as they can damage the surface of your piece.

Additionally, you should inspect your anodized aluminum for any signs of corrosion or wear and tear on a regular basis. If any damage is found, you should take appropriate action to fix it right away.

Finally, make sure to seal your anodized aluminum with a clear coat or wax after each cleaning session to protect it from further damage.

Why should you anodize aluminum?

Anodizing is a process that can be used to make a project last longer. It also can be used to make the project look better. This process helps to protect your aluminum piece from corrosion and wear, making it ideal for many different applications.

Additionally, anodizing can be used to create different aesthetic effects, making it a great option for decorative projects. Anodizing aluminum is a process that helps to protect your piece and make it last longer.

Read the safety instructions before beginning the process. Inspect your finished product for any damage or wear. With proper care, you can make sure your anodized aluminum lasts a long time.

Why do you need to wear safety gear when anodizing aluminum?

It is important to wear the necessary safety gear when anodizing aluminum, as it can be a dangerous process. This includes goggles, gloves, and protective clothing such as a long-sleeve shirt and pants.

Additionally, make sure that your work area is well ventilated. This will help to ensure that any fumes are not inhaled.

How does anodizing aluminum work?

Anodizing is a process in which electricity is used to create a chemical reaction on the surface of aluminum. This reaction creates a layer of oxide, which helps protect the metal from corrosion and wear.

The thickness of this layer can be controlled, making it ideal for projects that require extra protection or color.

What are the benefits of anodizing aluminum?

Anodizing aluminum has many benefits, including increased protection against corrosion and wear. It also helps to make the surface more durable, which can help increase its lifespan.

Anodizing also increases aesthetic effects, making it a great option for projects that require extra protection or color. Additionally, anodizing aluminum is a relatively inexpensive process.

Does anodizing aluminum change the weight of a piece?

No, anodizing aluminum does not significantly change the weight of a piece. The process does add a thin layer of oxide to the surface, but this is usually too small to have any noticeable effect on the overall weight.

Therefore, anodizing can be used for projects where weight needs to be kept to a minimum.

Can anodized aluminum be polished?

Yes, anodized aluminum can be polished to make it look new again. But you have to be careful what you use to polish it. Abrasive cleaners or materials can damage the finish of your piece.

So use a mild cleaner and soft cloth instead. Also, remember to put a clear coat or wax on your anodized aluminum after polishing it. This will help protect it from getting damaged again.

Does anodizing aluminum weaken it?

No, anodizing aluminum does not weaken it. In fact, the process helps to strengthen and protect the metal from corrosion and wear. Anodizing also increases the durability of a piece, making it last longer.

However, you should take care when using your anodized aluminum as any rough treatment can cause damage.

Do you need to seal anodized aluminum?

Yes, it is important to seal your anodized aluminum after each cleaning session. This will help protect it from further damage and keep it looking good for longer.

You can use a clear coat or wax as a sealant, but make sure that these products are specifically designed for anodized aluminum.

Does anodizing aluminum increase its cost?

No, anodizing aluminum does not significantly increase its cost. The process adds a layer of protection to the metal and can make it look more attractive, but it usually won’t add much to the overall price tag.

Anodizing is also relatively inexpensive when compared with other methods of metal finishing, making it a great option for projects on a budget.

Do you need specialized tools to anodize aluminum?

No, you do not need any specialized tools to anodize aluminum. All you need is a few basic supplies such as stainless steel or copper rods, a DC power source, and lye or acid solution.

It’s important to use the right supplies and follow all safety precautions during the anodizing process.

Does anodizing aluminum affect its weldability?

No, anodizing aluminum will not make it harder to weld. But you have to be careful when welding anodized metal because it can get damaged from the heat. The best way to weld anodized metal is using a low-heat process like MIG or TIG welding.

Can you anodize aluminum at home?

Yes, it is possible to anodize aluminum at home. But it’s important that you take the necessary safety precautions and use the right supplies for the job. It might be a good idea to get some guidance from a professional before attempting this process at home.

Anodizing aluminum is a useful process that can help increase the lifespan and aesthetics of a piece. With the right supplies and safety precautions, it’s possible to anodize aluminum at home.

Does anodizing aluminum reduce electrical conductivity?

No, anodizing aluminum does not reduce its electrical conductivity. The process simply adds a layer of oxide to the surface of the metal which helps to protect it from corrosion and wear.

However, you should take care when using anodized aluminum in electrical applications as any damage to the coating could lead to a reduction in conductivity.

Do you need to clean anodized aluminum?

Yes, it is important to clean your anodized aluminum regularly. This will help remove dirt, grime and other contaminants that can affect the finish of your piece.

Use a mild cleaner or soap with warm water and a soft cloth to keep your anodized aluminum looking its best. Make sure not to use any abrasive materials as they can damage the finish.

Can you color anodize aluminum?

Yes, it is possible to color anodize aluminum. This process uses dyes in the anodizing bath that can give the metal a wide variety of colors and shades.

The colouring will last longer than paint or other finishes, but it can fade over time if not properly maintained.

Is anodizing aluminum a long-term solution?

Yes, anodizing aluminum is a great long-term solution for metal finishing. Anodized aluminum is more durable than other finishes and can resist corrosion and wear better over time.

However, it may require occasional cleaning or sealing in order to keep its protective qualities intact.

Is there a way to repair anodized aluminum?

Yes, it is possible to repair damage on anodized aluminum. Depending on the extent of the damage, you may be able to use abrasive compounds or polishes to restore the finish.

However, if the damage is too severe, you may need to replace the part or have it professionally repaired.

Are there any tips for working with anodized aluminum?

There are some things that you can do to make sure that you get the best results when working with anodized aluminum.

- First, use a low-heat welding process like MIG or TIG welding when joining pieces together.

- Second, always follow safety precautions and use the right supplies for the job.

- Lastly, take care when cleaning or repairing anodized aluminum so you don’t damage the finish.

How often should you reseal anodized aluminum?

You should reseal anodized aluminum every year or two to keep it from corroding and wearing out. Resealing will also help keep the color from fading. Be sure to use a sealant that is made specifically for anodized aluminum for the best results.

Anodizing aluminum is a process that helps make things last longer and look better. With the right materials and being careful, you can do it at home or fix any damage that might happen later.

How long does anodized aluminum last?

Anodizing aluminum is a durable finish that can last for many years if properly maintained. The lifespan of anodized aluminum depends largely on its environment and how it’s used.

If taken care of well, anodized aluminum should be able to hold up for many years without needing any major repairs or refinishing.

When should you replace anodized aluminum?

If your anodized aluminum is worn out or has corrosion, you need to replace the part. If you can’t fix it yourself, ask a professional for help. They will know what to do to make your metal look and work like new again.

Anodizing is a process that helps to protect aluminum and make it last longer. With proper care, you can make sure your anodized aluminum lasts for years.

Clean it regularly, reseal as needed, and replace any pieces that are too damaged to repair. That way, you’ll know that your anodized aluminum is safe and secure.

Which sealant should you use for anodized aluminum?

When resealing anodized aluminum, it’s important to choose the right sealant. Look for one that is specifically formulated for use on anodized aluminum.

This will help ensure that your metal looks and works its best for as long as possible. Make sure to follow the manufacturer’s instructions for best results.

How do you clean anodized aluminum?

Cleaning anodized aluminum is easy. You only need warm water, mild soap, and a soft cloth to wipe the surface down. Be careful not to use anything abrasive that could scratch the surface.

If there are areas of dirt or grime that won’t come off easily, you can use a brush with soft bristles. If necessary, you can also use a mild detergent to get rid of residue. Once the surface is clean, be sure to dry it thoroughly with a soft cloth.

How do you check for anodized aluminum?

If you’re not sure if something is anodized aluminum or not, look for signs that it has been treated with a protective layer. Anodizing will usually make the aluminum have a darker color and be shiny or glossy.

You may also see some etching on the surface in areas where it has been treated. Lastly, you may hear a metallic clicking noise when tapping on the surface. This is an indication that the piece has been anodized and it’s a good sign of quality.

How many watts should you use for anodizing?

The amount of current used when anodizing aluminum can have a big impact on the final product. It’s recommended to use between 1-3 amps per square foot when working with aluminum and other metals.

Too much current can cause pitting or burning, so be sure to consult a professional if you’re unsure. Taking the time to get the wattage right can make all the difference in how your anodized aluminum looks and performs.

How much does it cost to anodize aluminum?

Anodizing is a process that can make aluminum stronger. The cost to do this process varies depending on how big the project is and how many parts there are. Most projects will cost from $50-$250 for just one part.

If you have bigger pieces or more parts, it will cost more money. The best way to find out how much it would cost for your project is to ask someone who does this type of work for a living.

Should you anodize aluminum at home?

Anodizing aluminum is a process that requires special equipment and knowledge in order to do it properly. If you don’t have the right tools or experience, it’s best to leave this job to professionals who can get the job done right.

Trying to do it yourself could end up costing more money than hiring a professional. It can also be dangerous if you don’t know what you’re doing, so it’s better to leave it up to the experts.

What if something goes wrong when anodizing aluminum?

If you’re working with anodized aluminum and something goes wrong, it’s important to act quickly. First, check the part for any damage or defects. If there is a small problem, you may be able to fix it yourself.

Try resealing the area or using a mild detergent to clean it. If the problem is more serious, it’s best to contact a professional for help.

Does anodizing aluminum increase its strength?

Yes, anodizing aluminum can significantly increase its strength and durability. This is because the protective layer created by the process helps prevent corrosion and wear-and-tear.

Anodized aluminum is also resistant to scratches, dents, and other types of damage.

Useful Video:ShopBuilt – How to Anodize Aluminum!

Conclusion

If you want to anodize aluminum at home, there are a few things you need to know. First, anodizing creates a protective oxide coating that is thicker and harder than the original aluminum surface.

This makes it ideal for applications where durability and corrosion resistance are important. Anodized aluminum also has a unique aesthetic that can be enhanced with dyes or left in its natural state.

The process of anodizing aluminum is relatively simple, but it does require some specialized equipment. With a little patience and care, you can achieve professional-quality results from the comfort of your own home workshop.

Just remember to take the necessary safety measures and consult a professional if you ever find yourself in over your head.

References:

- https://makeitfrommetal.com/how-to-anodize-aluminum-at-home/