Choose the Best Metal Lathe for Home Shop

Customer’s Choice: the Best RatedMetal Lathes for Home Shop

614 users answered this survey. Please help us improve this review!

A metal lathe is an important tool for any home shop. It can be used to create a variety of objects, from simple screws to complex machine parts. In this comprehensive guide, we will discuss the different types of metal lathes available on the market today, and provide product reviews for the best models. We will also offer useful tips on how to choose the right metal lathe for your needs, and show you how to get the most out of your machine. So whether you are just starting out in machining or you are looking for an upgrade, read on for all the information you need to make the best purchase decision possible!

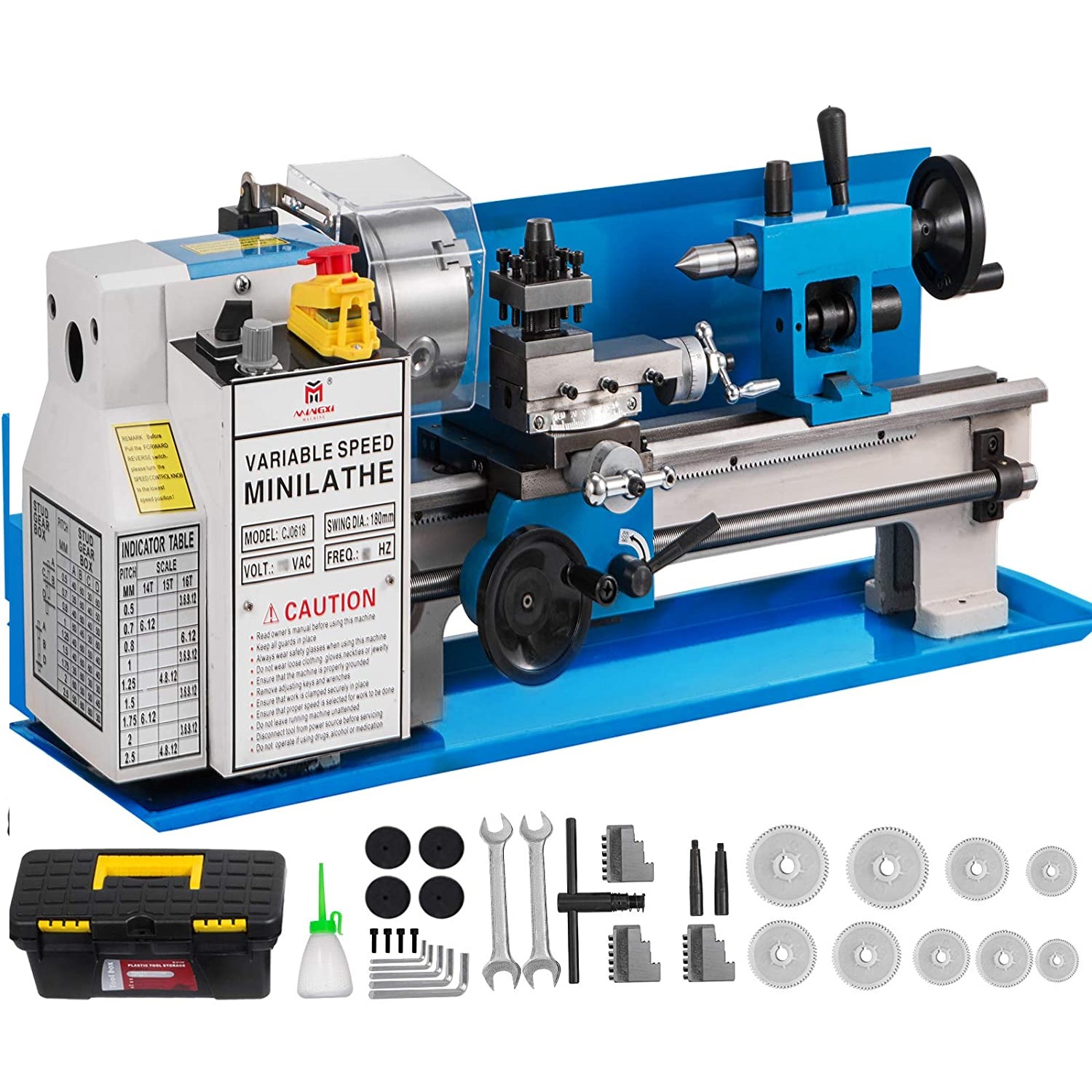

BestEquip Metal Lathe 7″ x 14″,Mini Metal Lathe

Looking for a mini lathe that can handle a variety of materials and projects? Look no further than the BestEquip Metal Lathe 7″ x 14″!

Looking for a mini lathe that can handle a variety of materials and projects? Look no further than the BestEquip Metal Lathe 7″ x 14″!

The robust bed is made of high-grade iron, meaning it can withstand repeated use without succumbing to wear and tear. If you plan on working mainly with softer materials, you will be left more than impressed. Additionally, the lathe features variable speeds ranging from 0 to 2500 RPM, so you can tailor the speed to the material you’re working with. Plus, with its many applications, the BestEquip Metal Lathe is a great choice for anyone looking to add a versatile tool to their workshop.

This mini metal lathe is perfect for all your small-scale machining needs, and it comes with a variety of features that make it easy to use. However, please note that this product does not come with tool holders, so you’ll need to purchase those separately. Additionally, the tolerance is low on this machine, so be careful when machining delicate parts. The speed change isn’t smooth either, so take care when adjusting the RPMs. Finally, be aware that the tools are poorly lined-up and vague instructions won’t make your job easier either.

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe

Do you want a versatile, high-quality mini lathe for your project? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This reliable, precision-engineered lathe is perfect for small projects and soft materials.

Do you want a versatile, high-quality mini lathe for your project? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This reliable, precision-engineered lathe is perfect for small projects and soft materials.

If you’re looking for a cheap and cheerful way to get into metal milling, then the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe is certainly worth considering. However, it’s worth bearing in mind that this is an entry-level machine, so don’t expect miracles. The instructions are vague, and the details come loose easily. From this it’s clear that the build quality is not the best, and it can be a bit fiddly to set up and get running smoothly. Once you’ve got it going, it doesn’t have a huge amount of power, so complex jobs may be beyond its capabilities. Nevertheless, it’s a decent little machine for simple milling tasks, and at this price it’s definitely worth checking out.

Shop Fox M1015 6-Inch by 10-Inch Micro Lathe

Looking for a versatile, affordable micro lathe? Check out the Shop Fox M1015! This lathe is great for hobbyists and small shops alike, with variable spindle speed from 100 to 2000 RPM.

Looking for a versatile, affordable micro lathe? Check out the Shop Fox M1015! This lathe is great for hobbyists and small shops alike, with variable spindle speed from 100 to 2000 RPM.

The Shop Fox M1015 6-Inch by 10-Inch Micro Lathe is far from a perfect lathe however. The specifications are misleading, it comes with no imperial fasteners, the quality of the spindle is poor, and the speed control leaves something to be desired. It also requires extra features for the best performance, making it a poor choice for anyone looking to get the most out of their lathe.

BestEquip Metal Lathe, 8″ x 16″ Benchtop Lathe

This 8″ x 16″ Benchtop Metal Lathe from BestEquip is perfect for anyone starting out in metalworking. It features a variable speed range of 0 to 2250 RPM, so you can easily adjust it to the right speed for the job.

This 8″ x 16″ Benchtop Metal Lathe from BestEquip is perfect for anyone starting out in metalworking. It features a variable speed range of 0 to 2250 RPM, so you can easily adjust it to the right speed for the job.

However this BestEquip Metal Lathe isn’t free of cons, this isn’t the case at all sadly. This benchtop lathe is perfect for hobbyists and DIYers of all levels of experience. This benchtop lathe is poorly constructed and requires a lot of effort to be set up properly. The customer support is bad, and you’re likely to lose the tool rest if you’re not careful. So, if you’re not up for figuring out how to get around these downsides, BestEquip Metal Lathe may not be for you.

TECHTONGDA 8X31” Precision Metal Lathe

Looking for a powerful and precise metal lathe? The TECHTONGDA 8X31” Precision Metal Lathe is perfect for your needs. Featuring a 900W brushless motor, this lathe can reach speeds of up to 2500 RPM, making it perfect for even the most delicate projects.

Looking for a powerful and precise metal lathe? The TECHTONGDA 8X31” Precision Metal Lathe is perfect for your needs. Featuring a 900W brushless motor, this lathe can reach speeds of up to 2500 RPM, making it perfect for even the most delicate projects.

This isn’t your average metal lathe. First of all, the dials are in metric measurements, so make sure you’re comfortable with those conversions before you start turning. Second of all, it may break belts, so be prepared to deal with that inconvenience. And finally, there’s no rotation direction switch on this machine, so be prepared to do a lot of finagling to get it going the way you want. Chuck may also need some re-adjustments depending on what you’re working with. But despite these quirks, it’s still a great metal lathe for the price. So if you’re willing to put in a little extra effort, this could be perfect for your workshop.

Buyers Guide

Metal Lathes in General

A metal lathe is a machine tool that removes material from workpieces by rotating them against a cutting tool. The workpiece is rotated on a spindle, while the cutting tool is fed into it. This action forms cylindrical shapes with smooth finishes.

Metal lathes are used in many industries, including automotive, aerospace, energy, and construction. They are also popular in home shops because they are versatile and relatively easy to use.

There are many types of metal lathes that could be ideal for a workshop. Let’s look at some of them.

Bench lathe

A bench lathe is a small, portable lathe that can be mounted on a workbench. They are typically used for small-scale projects, such as model making or repairing parts.

One of the main advantages of a bench lathe is that it is easy to set up and use. They are also relatively inexpensive, which makes them a good choice for beginners.

There are some disadvantages to bench lathes as well. They are generally not as powerful as larger lathes, so they cannot handle heavy-duty projects. And because they are small, they can be more difficult to work with large pieces of material.

CNC Lathe

A CNC lathe is a computer-controlled lathe that can be programmed to create specific shapes and sizes. This type of lathe is typically used in manufacturing because it is very precise. It’s widely used in the field of mass production.

They are very fast and efficient, and they can produce complex shapes with ease.

One downside to CNC lathes is that they require special training to use. They are also not as versatile as other types of lathes, so they may not be the best choice for a home shop.

Center Lathe

A center lathe is a type of engine lathe that is designed for machining round parts. It has a spindle in the center of the machine, and the workpiece is held between two centers.

Center lathes are very versatile and can be used to create a wide variety of shapes and sizes. They are utilized for a variety of different operations, like threading and grooving. These lathes are also relatively easy to use, which makes them a good choice for beginners.

Automatic Lathe

An automatic lathe is a type of lathe that is controlled by a computer. It can be programmed to create specific shapes and sizes, and it can also be used for mass production.

Automatic lathes are very fast and efficient, and they can produce complex shapes with ease. However, they are more expensive than other types of lathes, and they require special training to use.

High speed lathe

A high speed lathe is a type of lathe that is designed for machining high-strength materials. It has a spindle that rotates at very high speeds, and it uses special cutting tools to machine the workpiece.

High speed lathes are used in many industries, including aerospace, medical, and energy. They are also popular in home shops because they are versatile and relatively easy to use.

The main advantage of a high speed lathe is that it can handle a wide variety of materials. It is also very precise and can produce complex shapes with ease. However, one downside to this type of lathe is that it is more expensive than other types of lathes.

Tool room lathe

A tool room lathe is a heavy-duty lathe that is designed for precision work. It is typically used in manufacturing and industrial applications.

Tool room lathes are very precise and can handle complex projects. However, they are more expensive than other types of lathes, and they require special training to use.

What are Mini and Micro Lathes?

Mini and micro lathes are small, portable lathes that can be used for a variety of projects.

Mini lathes are typically used for small-scale projects, such as model making or repairing parts. Micro lathes are even smaller and more delicate, and they are often used for jewelry making or other precision work.

Both mini and micro lathes offer a lot of advantages. They are easy to set up and use, and they are relatively inexpensive. However, they are not as powerful as larger lathes, so they may not be able to handle heavy-duty projects.

How Can You Utilize a Metal Lathe in Your Workshop?

There are many ways you can utilize a metal lathe in your workshop. You can use it to create parts for projects, or you can use it to repair existing parts. You can also use it to create decorative items, such as bowls or vases. [1],[2],[3],[11]

How to Maintain a Metal Lathe Properly?

In order to maintain a metal lathe properly, you should regularly oil the moving parts and clean the machine. You should also inspect the machine for any wear or damage, and you should replace any worn or damaged parts. Regular maintenance will help ensure that your lathe lasts for many years.

Lathe can be cleaned with a damp cloth and then dried with a clean, dry cloth. You should oil the moving parts of the lathe regularly to keep them from rusting. And you should inspect the machine regularly for any wear or damage. If you find any worn or damaged parts, you should replace them right away.

To find out if one of your machine parts needs a replacement, you can consult your lathe’s manual. Otherwise, you can take your lathe to a professional for an inspection. Either way, it’s important to keep your lathe in good working condition so that it will last for many years. Not doing so will not only cause your lathe to break, or ruin the material but also, it can cause serious injury.

Operating a lathe can be dangerous if the proper safety procedures are not followed. Always wear proper safety gear, such as gloves, goggles, and ear protection and check if the elements of your lathe and the workpiece are secure before turning the machine on. [1],[4]

Buyers Guide for the Best Metal Lathes for Home Shop

Size of your project, lathe and your workshop

The first thing you need to think about when choosing a metal lathe is the size of your projects. If you’re only going to be working on small pieces, then a mini lathe might be all you need. But if you’re planning on working on larger projects, then you’ll need a full-size lathe. The next thing to consider is the size of your workshop. If you have a small workspace, then you’ll need to choose a compact lathe that doesn’t take up too much space. And finally, think about what type of materials you’ll be working with.

But if you want to work with harder metals like steel, then you’ll need a heavy-duty lathe that can handle the extra wear and tear. [5],[7],[8],[10],[12]Structure of the Lathe

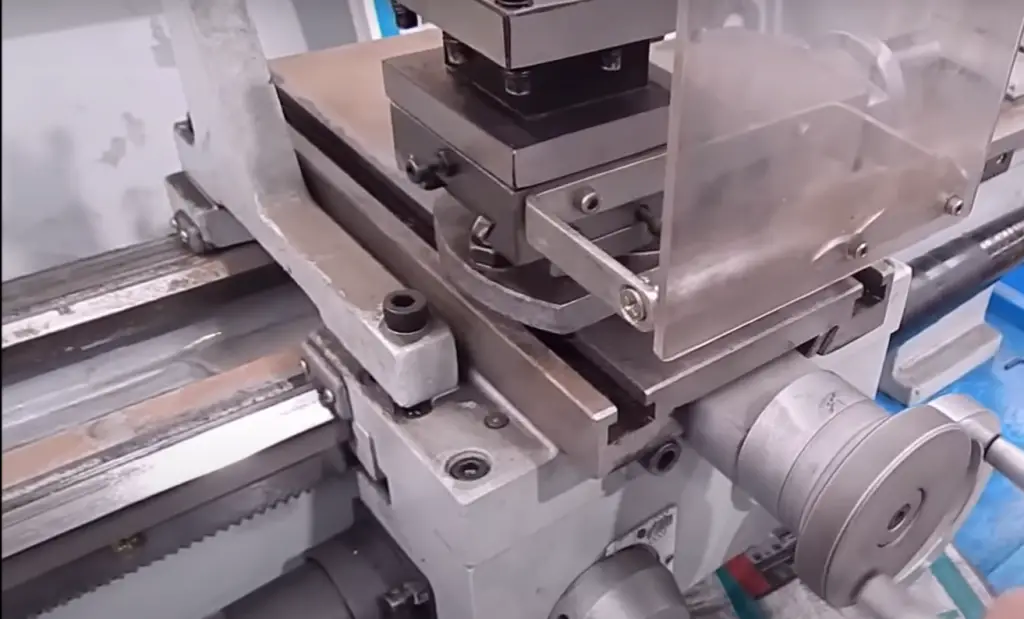

Yet another valuable aspect of a lathe is its structure. The lathe must be able to handle the weight and size of the workpiece without wobbling or vibrating. A good way to test this is to set the lathe up and turn it on, then gently touch the workpiece to see if there is any movement. If there is, then the lathe isn’t sturdy enough and you should keep looking.

Another important aspect of the lathe’s structure is how easy it is to access all of the different parts. You should be able to reach all of the controls and levers easily, without having to contort your body into uncomfortable positions. The last thing you want is to be struggling with the lathe while you’re trying to work. [7]

Your experience working with lathes

If you’re a beginner, then you’ll want to look for a lathe that is easy to use and has good customer support. It’s also important to find a lathe that is durable, so you don’t have to replace it after a few months. On the other hand, if you’re more experienced, then you’ll want a lathe that is more powerful and can handle more complex projects. You should also be looking for a lathe that offers more features and options if you have more experience. A good way to find out if a lathe is suitable for your needs is to read online reviews from other users. [5],[7]

Design of the lathe

When it comes to metal lathes, the design is important for a number of reasons. First, you want a lathe that is going to be able to handle the type of work you need it to do. If you are only going to be working with small pieces of metal, then a small lathe should be fine. However, if you are planning on working with larger pieces of metal, then you will need a lathe that is designed for that purpose. Secondly it’s important to see how easy the lathe is to set-up and use. If you are new to using a lathe, then you will want one that is easy to use so you don’t have to spend hours trying to figure it out. Lastly, more often than not, lathes with complex designs have more features than those with simpler designs. So, if you need a lathe with more features, then you will want to look for one that has a more complex design.[7],[10],[12]

Speed

One of the most important things to consider when choosing a metal lathe is the speed. You’ll want to make sure that the lathe can reach the speeds you need for your project. The speed is usually measured in revolutions per minute (RPM). For most projects speed of around 2500 RPM is a perfect choice.

Another thing to keep in mind is that some lathes have variable speed, while others have a fixed speed. Variable speed means that you can adjust the speed of the lathe to suit your needs. Fixed speed means that the lathe will always turn at the same speed.

Generally speaking, faster is better when it comes to metal lathes. That’s because higher speeds allow you to remove material more quickly and achieve a smoother finish on your workpiece. However, there are some projects where a lower speed is better. For example, if you’re working with very delicate material, you’ll want to use a lower speed to avoid damaging it.

Lathes with variable speed are more versatile and can be used for a wider range of projects. However, they tend to be more expensive than lathes with fixed speed. If you’re just getting started with metalworking, a lathe with fixed speed may be a good option for you. [6],[8]

Wattage

When it comes to lathes, more watts is not necessarily better. In fact, for most home shop applications, a lathe with a 700-watt motor will be more than enough power. If you’re working with larger or tougher materials, you may need a lathe with a 1000-watt motor.

So, when choosing the best metal lathe for your needs, pay attention to the wattage rating and choose the right model for your application. [6],[8]

Affordability

Of course, one of the most important factors to consider when choosing a metal lathe is affordability. There are a wide range of lathes available on the market, from budget-friendly models to high-end professional lathes.

If you’re just getting started with metalworking, then a budget-friendly model may be the best option for you. These lathes typically have fewer features than more expensive models but they’re still capable of doing great work. As you become more experienced, you can always upgrade to a more expensive lathe. [5],[7],[10],[12]

Warranty

Another important thing to consider when choosing a metal lathe is the warranty. Most lathes come with a one-year warranty, but some brands offer longer warranties. If you’re planning on using your lathe for heavy-duty applications, then it’s worth paying extra for a lathe with a longer warranty. That way, if something goes wrong, you’ll be covered.

When it comes to warranties, always read the fine print to make sure you understand what’s covered and what’s not. Some warranties only cover the lathe itself and not the accessories. Others may only cover defects in materials or workmanship and not normal wear and tear. Be sure to understand what’s covered before you buy so you know what to expect if something does go wrong. [7],[8]

Additional Features

Some metal lathes come with additional features that can be helpful for certain applications. For example, some lathes have a built-in coolant system that can be used to keep your workpiece cool while you’re machining it. This is especially useful when working with hard metals that tend to heat up quickly.

We recommend choosing a lathe with additional storage space for holding your tools and accessories. This will help you keep your work area tidy and organized and make it easier to find the tools you need when you need them.

When choosing a metal lathe, be sure to consider all of the features that are available and choose the ones that are most important to you.

The compound slide rest allows you to make more complex cuts and shapes with your lathe. It’s a must-have for any serious metalworker.When it comes to toolholders, a 4-way tool post is the most versatile option. It allows you to hold four different tools at once, which makes it great for complex projects. If you’re just getting started with metalworking, then a simple tool post may be all you need. [8],[9],[10],[12]

FAQ

What size metal lathe is the best for general work?

The best size metal lathe for general work will depend on what you plan to use it for. If you just need something for small projects around the house, then a mini lathe would be a good choice. However, if you are looking to do more serious work, such as making parts for a car or motorcycle, then a larger lathe would be better suited.

Some other things to consider when choosing the best size metal lathe for your needs include the type of projects you plan to use it for and the amount of space you have available.

Is a mini lathe worth the money?

This is a difficult question to answer. It depends on what you plan to use it for and how often you plan to use it. If you just need something small to occasionally touch up projects, then a mini lathe might be a good investment. However, if you plan on using it more frequently or for larger projects, then a full-size lathe would be worth the investment.

Another factor to consider is the size of the projects you plan to work on. A mini lathe might not have the power or capacity to handle some of the larger projects. So, if you know that you’ll be working on larger projects, then a full-size lathe would be your best bet.

What is a good metal lathe?

Lathes come in a range of sizes and styles, so it’s important to choose one that will best suit your needs. If you’re looking for a heavy-duty lathe that can handle large projects, then you’ll want to consider an industrial-grade machine. However, if you’re only planning on using your lathe for smaller projects around the workshop, then a mini lathe might be a better option.

How useful is a metal lathe?

A metal lathe is an extremely versatile tool that can be used for a wide variety of projects. Whether you’re a professional machinist or a hobbyist, a metal lathe can help you create parts and products with incredible precision. In addition to being able to create accurate and intricate designs, metal lathes also offer the ability to mass produce parts quickly and efficiently.

Conclusion

A metal lathe is a very versatile tool and can be used for a variety of purposes, you can both create and repair metallic parts with it.

It can be tough to decide which metal lathe is the best for your home shop. Hopefully, this article has given you a few things to consider when making your decision. Keep in mind the size of your home shop where you plan to use the lathe in, the price, how easy it is to use and set up, and of course the warranty.

In this article we outlined some of the most popular types of metal lathes, so you can make an informed decision about which one will work best for you. In addition, we’ve covered five of the most popular metal lathes on the market; whichever one you choose, we know you’ll enjoy hours of crafting fun!

References:

- https://www.ametals.com/post/what-is-a-lathe-and-how-does-it-work

- https://machineryfuture.weebly.com/knowledge/lathe-machine-04

- https://machinefanatic.com/what-does-a-lathe-do/

- https://littlemachineshop.com/images/gallery/info/MiniLatheUsersGuide.pdf

- https://homemakerchic.com/best-metal-mini-lathe/

- https://handymansworld.net/best-mini-metal-lathes/

- https://www.architecturelab.net/best-metal-lathe/#Mini_Metal_Lathe_vs_Metal_Lathe

- https://www.electronicshub.org/best-metal-lathes/

- https://www.sharpen-up.com/best-metal-lathe-money-top-5-reviewed/#Metal_Lathe_Buyers_Guide

- https://www.mechanicwiz.com/best-metal-lathe-for-home-shop/

- https://ratemywelder.com/best-metal-lathe-home-workshop/#Benefits_of_Using_a_Metal_Lathe

- https://toptennotch.com/best-metal-lathe-for-home-shop/