Choose the Best Drill Press for Metal

Customer’s Choice: the Best Rated Drill Presses for Metal

48 users answered this survey. Please help us improve this review!

Are you looking for the best drill presses for metal? Whether you’re a beginner or an experienced metalworker, this growing guide will help you choose the right drill press for your needs. In this article, we’ll discuss the different types of drill presses available and provide product reviews of some of the best models on the market. We’ll also give you some tips on how to use a drill press safely and effectively when working with metal. So if you’re ready to learn more about the best drill Presses for your workshop, keep reading!

WEN 4208T 2.3-Amp 8-Inch 5-Speed Benchtop Drill Press

Looking for a drill press that can handle any job you throw at it? The WEN 4208T 2.3-Amp 8-Inch 5-Speed Benchtop Drill Press is perfect for anyone who needs a versatile and powerful tool.

Looking for a drill press that can handle any job you throw at it? The WEN 4208T 2.3-Amp 8-Inch 5-Speed Benchtop Drill Press is perfect for anyone who needs a versatile and powerful tool.

With five different speed settings, this drill press can tackle any project. The 1/3 HP induction motor provides ample torque and power, making it easy to get the job done quickly and efficiently. assembly is simple and straightforward, so you’ll be up and running in no time. And with its great value for the price, the WEN 4208T is a smart choice for anyone in the market for a new drill press.

This WEN drill press is a tough piece of equipment that’s built to last. Its powerful motor can handle even the most difficult drilling tasks, while its cast iron construction ensures superior stability and precision. Plus, this drill press comes with a variety of handy features.

But be careful: some users have reported that the screws on this drill press can come loose quite easily. So make sure you check them regularly and keep them tightly in place. Also, the lid that covers the belt has a loose screw which could potentially fall off if not fixed. The drill press also will take your time to disassemble it. And finally, be aware that the base plate is just under 1/4 of an inch thick so it might not be able to handle the weight of some heavier projects.

Overall, this is a great drill press for metalworking. It’s well-built, powerful, and easy to use. Just be sure to keep an eye on the screws and you’ll be good to go.

SKIL 3320-01 3.2 Amp 10-Inch Drill Press

Looking for an affordable drill press that gets the work done? The SKIL 3320-01 3.2 Amp 10-Inch Drill Press is a great option for anyone on a budget.

Looking for an affordable drill press that gets the work done? The SKIL 3320-01 3.2 Amp 10-Inch Drill Press is a great option for anyone on a budget.

This drill press comes with a 1/2-inch keyed chuck, making it easy to use with a variety of different bits and attachments. It also has a bump-off switch for more safety, as well as 5 different speed settings to make drilling through different materials easier. Plus, the laser X2 2-beam alignment system ensures that your holes are always perfectly aligned.

The SKIL 3320-01 is a great budget drill press. It’s powerful enough to handle most drilling tasks, and it comes with a variety of handy features. The laser alignment system is a nice touch, and the bump-off switch is a must-have for safety.

However, this drill press does have some downsides. First, the cast aluminum base collar is fragile and easily dented, while the rattly motor makes it nearly impossible to get precise results. Second, the quill is dry and cheap aluminum that doesn’t come with any lubricant, so it wears down quickly. Worst of all, the build quality is terrible – expect parts to fall off or break very easily. Finally, some users have reported that the chuck can come loose quite easily, so make sure you check it regularly and keep it tight.

Shop Fox W1668 3/4-HP 13-Inch Bench-Top Drill Press/Spindle Sander

The Shop Fox W1668 3/4-HP 13-Inch Bench-Top Drill Press/Spindle Sander is perfect for the home workshop. This versatile machine comes with a 3/4 HP motor and offers a 110-Volt performance. It has a swing of 13-1/4 inches and a spindle travel of 3-1/4 inches.

The Shop Fox W1668 3/4-HP 13-Inch Bench-Top Drill Press/Spindle Sander is perfect for the home workshop. This versatile machine comes with a 3/4 HP motor and offers a 110-Volt performance. It has a swing of 13-1/4 inches and a spindle travel of 3-1/4 inches.

The included 3-piece spindle sander drum kit with a mandrel and 80 grit sanding paper to fit the 1-Inch, 1-1/2-Inch and 2-Inch drums makes this machine perfect for sanding projects large and small. With spindle speeds of 250 to 3050 RPM, this drill press can handle any project you throw at it.

This drill press does come with its set of issues however. The vibration at high speeds is so extreme, it’s tough to keep it together. This drill is built to deliver power and precision at high speeds, but it unfortunately falls short in terms of build quality. Disassembling this drill is a real hassle, and it doesn’t always spin straight – which can cause serious problems when drilling into tough materials. What’s more, this drill has a tendency to walk away from the target, making it difficult to achieve precise results. But despite all its flaws, the The Shop Fox W1668 3/4-HP 13-Inch Bench-Top Drill Press/Spindle Sander is still one of the cheapest options on the market – so if you’re on a tight budget, it might be worth considering.

JET JDP-15B, 15-Inch Woodworking Drill Press, 115V 1PH, 3/4HP

The JET JDP-15B is a powerful and easy-to-use woodworking drill press. With one-handed belt tensioning, XACTA Laser technology for better drilling accuracy, and an LED work light to increase visibility, this drill press is perfect for any project, big or small.

The JET JDP-15B is a powerful and easy-to-use woodworking drill press. With one-handed belt tensioning, XACTA Laser technology for better drilling accuracy, and an LED work light to increase visibility, this drill press is perfect for any project, big or small.

The large table provides plenty of space for even the most ambitious projects, and the spindle can travel a full 3-1/8 inches, making it easy to drill precise holes.

But this expensive machine isn’t completely perfect. The depth stop is horrible, making it hard to get consistent results. And the rear pulley is a real pain to tighten, which can lead to frustrating errors.

JET J-2530, 15-Inch Benchtop Drill Press, 3/4-HP, 115V 1PH

The JET J-2530, 15-Inch Benchtop Drill Press is a versatile tool that’s perfect for your home workshop. With its 16 speeds, it can handle any drilling task you throw at it. The large ground steel column provides maximum support and ensures accurate drilling, while the telescoping spindle guard keeps your hands safe.

The JET J-2530, 15-Inch Benchtop Drill Press is a versatile tool that’s perfect for your home workshop. With its 16 speeds, it can handle any drilling task you throw at it. The large ground steel column provides maximum support and ensures accurate drilling, while the telescoping spindle guard keeps your hands safe.

Plus, the 1-7/8″ diameter quill lets you drill into even the toughest materials. So if you’re looking for a quality drill press that won’t take up too much space, the JET J-2530 is the perfect choice.

It does come with some issues though. The J-2530 has some problems with how it runs, which means your projects might not turn out as precise as you’d hoped because the chunk variety might be different from the one stated in the description.. Plus, the assembly instructions are unclear and the top is hard to lift without putting all your strength.

Buyer’s guide

What is a Drill Press?

A drill press is a machine that drills holes in materials such as wood, metal, or plastic. It consists of a base, a column or pillar, and a table. The table may be adjustable to allow the user to drill at various angles.

The operator controls the depth, speed, and angle at which the drill bit penetrates the workpiece.Most drill presses have a columnar design, meaning they consist of a base, column, and head (which houses the motor and chuck). This design gives them a large footprint but also makes them very stable during use. [1],[2]

The first drill press was invented in the 18th century by two men named Arthur James Arnot and William Blanch Brain. The first drill press came with a motor and a handle to work with. [3]

There are two main types of drill presses: floor-standing models and benchtop models. Floor-standing drill presses are the largest and most powerful type of drill press. We will discuss more about them below. [1],[2]

Advantages of Drill Press Over the Regular Drill

There are plenty of differences between regular drills and drill presses. The most notable advantage of drill presses is the power and accuracy that they offer.

Drill presses are designed to bore holes into tougher materials with greater precision than regular drills. The fact that they are stationary also makes them much easier to use, as you can apply more pressure without worrying about the drill moving around.

Another big advantage of drill presses is that they come with a chuck, which is a clamp that holds the drill bit in place. This means that you can change out bits quickly and easily, which is essential for certain projects.

Finally, most drill presses have a large table that can be used to support the workpiece during drilling. This helps to keep things steady and prevents the material from moving around while you’re working.

All of these factors combine to make drill presses an essential tool for anyone who does a lot of drilling, whether it’s for metalworking, woodworking, or any other type of project.

The disadvantage of drill presses is that they are more expensive than regular drills and they take up more space. However, if you do a lot of drilling, we think the advantages outweigh the disadvantages. [2]

Types of Drill Presses

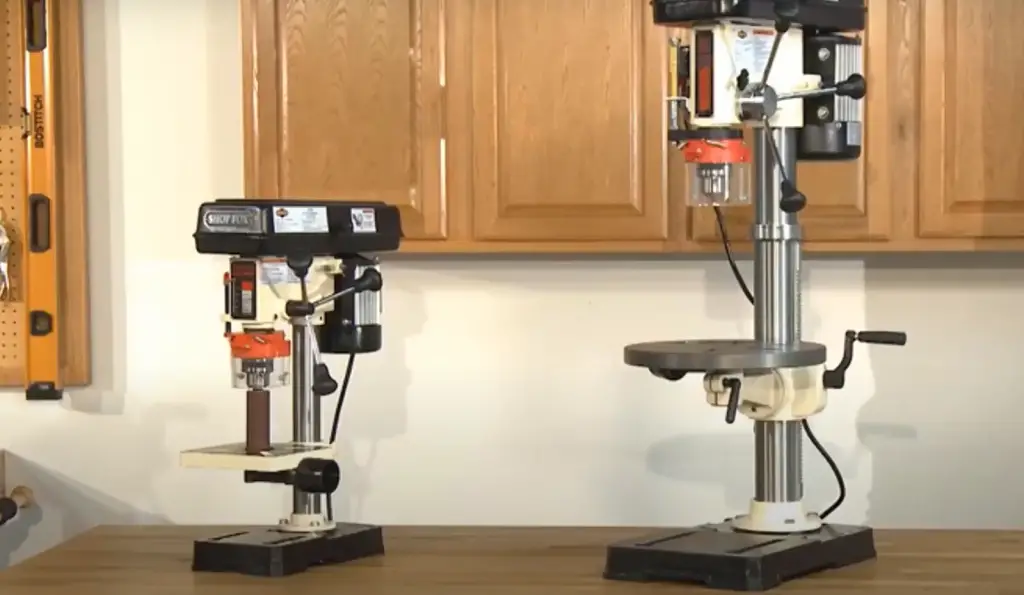

As we mentioned before, there are two main types of drill presses: floor-standing models and benchtop models.

Floor-standing

Floor-standing drill presses are the largest type of drill press. They are designed for heavy-duty tasks and have a large footprint to match. These models usually come with several different features that make them more versatile, such as adjustable speed settings and a built-in light. Floor-standing drill press can drill not only metals but also concrete and wood.

The biggest advantage of floor-standing drill presses is their power. These models are designed for heavy-duty tasks, so they can easily drill through tougher materials like metal or concrete. They also come with more features than other types of drill presses.

The downside of floor-standing drill presses is that they are the most expensive type and they take up the most space. If you don’t have a lot of room in your workshop, then one of the other types might be a better option for you. [1],[2],[4],[5],[6]

Benchtop drill presses

Benchtop drill presses are smaller than floor-standing models but they still offer plenty of power and accuracy. Benchtop drill presses are great for those who don’t have a lot of space in their workshop or garage. These smaller, portable models offer plenty of power and accuracy to get the job done right no matter where you are.

These models can do a lot of the same tasks as floor-standing drill presses, but they are not as powerful. However, they are still more than capable of drilling through metal and other tough materials.

Benchtop drills presses can be a great option for those on the budget. They are less expensive than their floor-standing counterparts, so if you need to save some cash and still get all of your work done in one spot without sacrificing quality then this might just do it.

A disadvantage of benchtop drill presses is that they can be difficult to move around because of their size and weight. If you need to move your drill press often, then one of the other types might be a better option for you. [1],[2],[4],[5],[6]

Safety Tips You Should Consider When Using a Drill Press

Drilling can be a dangerous activity if proper safety precautions are not taken.

Keep your hands and fingers away from the bit at all times so that you don’t get caught by surprise while making adjustments or if there’s an unexpected interruption such as someone coming into view behind the machine! Make sure everything stays clear of any clothing which might cause distractions during work time- this includes both long hair on top but also anything below the waistline since those areas usually move around more than other parts do due their proximity to the ground.Keep in mind the temperature of the drill press as well- if it’s been running for a while, the bits can become quite hot and cause burns if they come into contact with skin. Another potential hazard is flying debris created when metal is being drilled; small particles can ricochet off other surfaces in the immediate area so always be aware of your surroundings to avoid getting hit by anything.

Be aware of your surroundings and take note of anything which might be a potential hazard, such as power cords running across the floor where someone could trip over them. Keep children and pets away from the work area to prevent any accidents. If possible, it’s best to have someone else in the room with you so that they can act as a spotter in case of an emergency.

You should also never hold a metal piece in your hand while drilling as this can cause serious injuries if the drill bit were to slip. Always use a clamp or vise to secure the workpiece before beginning any drilling operation.

Adjust the speed accordingly for the type of material you’re drilling– lower speeds are better for harder metals while higher speeds work best on softer materials. If you’re not sure what speed to use, it’s always better to err on the side of caution and start with a slower setting before increasing the speed.

Last but not least, always unplug the drill press before making any adjustments or changing out bits! This will ensure that there’s no accidental power surges which could seriously injure someone who may be working on the machine at the time.

Following these safety tips will help ensure that you have a safe and enjoyable experience while using your drill press! [1],[2],[4]

How to Take Care After Your Drill Press?

Once you’re done using your drill press, it’s important to take care of it so that it lasts for a long time.

Take care of your drill press so that you can get many years out of it!

First, unplug the machine and allow it to cool down before cleaning.

Second, use a soft cloth on all surfaces with mild soap or oil if needed for ornamental purposes only – never leave dirty liquid tribute at home–and wipe away any debris from inside where dust bunnies hide when not working their mischief upon unsuspecting victims who might find themselves without ventilation after such festivities have been conducted posteriorly (that’s “tail”).

Thirdly, perform an inspection tour through each section, looking for ways that have been strained during use so as to prevent any further wear and tear; tighten screws, re-align moving parts, and so on. Add a dab of oil to each friction point (not the electrical ones, obviously) both for easier movement in the future as well as lubrication which will help discourage rust or corrosion.

Fourth, give the whole thing a good once-over with a clean cloth just to make sure you didn’t miss anything in your post-operative analysis.

Finally, store it in a safe place where it can’t be damaged – cover loosely with a sheet if you’re worried about curious critters who like to nibble on power cords.

If you’re looking for a new drill press, check out our reviews below. We’ve included both floor-standing and benchtop models to suit a variety of needs and budgets. And be sure to read our buyer’s guide at the end for more information on how to choose the right drill press for your shop.

If you are in the market for a new drill press, there are a few things you should keep in mind before making your purchase. In this buyer’s guide, we will go over some of the most important factors to consider when shopping for a drill press for metalworking.

Type of Projects

First and foremost, you need to decide what kind of projects you will be using the drill press for. Are you looking to do simple drilling jobs or more complex ones? If you only plan on doing simple drilling jobs, then a lower-end model should suffice. However, if you want to do more complex projects that require more precision, then you will need to invest in a higher-quality model.

Next, you need to take into consideration the size of the projects you will be working on. If you only plan on working on small projects, then a compact drill press would be a good option. However, if you plan on working on larger projects, then you will need to purchase a full-size drill press.

Finally, you need to decide what type of power source you want for your drill press. There are two main types of power sources: electric and pneumatic. Electric models are more common and are typically more affordable. Pneumatic models are less common but offer more power and can be used in more difficult applications.

Drill Press Features

Now that you have decided what type of projects you will be using the drill press for, it is time to start looking at the different features offered by each model.

Chuck

First, you need to decide what type of chuck you want. There are three main types of chucks: keyed, keyless, and Jacobs. The capacity of the chuck is also an important consideration. The capacity is the largest size bit that the chuck can hold. [5],[7]

Spindle Travel

Spindle travel is the measure of how far the spindle can move up and down. The majority of drill presses have a spindle travel of about five inches. However, some models have a spindle travel of six or more inches. If you plan on doing a lot of drilling, then you will need to purchase a model with a longer spindle travel. [1],[5]

Speed

The speed of the drill press is measured in revolutions per minute (RPM). The higher the RPM, the faster the drill press can drill. Most drill presses have a speed of about two to three thousand RPM. Softer metals will require a higher speed, while harder metals will require a lower speed. [1],[5]

Power

The drilling power of the drill press is measured in horsepower (HP). The higher the HP, the more powerful the drill press is. If you plan on doing a lot of heavy-duty drilling, then you will need to purchase a model with a higher drilling power. [1],[5]

Table Size

The size of the table is an important consideration for two reasons. First, the larger the table, the more space you will have to work on your projects. Second, the larger the table, the more weight it can support.

Most drill presses come with a standard-size table. However, some models come with an extended or wide-table. These tables provide more space and can support more weight. [1],[5]

Swing size

The swing size is the measurement of the largest diameter bit that can be used with the drill press. If you plan on drilling large holes, then you will need to purchase a model with a larger swing size.

As you can see, there are a lot of factors to consider when purchasing a drill press for metalworking. By keeping these considerations in mind, you will be able to find the perfect model for your needs. [1],[5],[7]

FAQ

What is the difference between a benchtop drill press and a freestanding drill press?

A benchtop drill press is a small, portable drill press that can be mounted on a workbench or table. A freestanding drill press is a larger, more powerful drill press that must be placed on the floor.

Both types of drill presses are designed for drilling holes in metal, but the benchtop model is usually not as powerful as the freestanding model.

Can you use a drill press on all metals?

No, you cannot use a drill press on all metals. The type of drill press and the size of the drill bit will determine what types of metal you can drill.

For example, some drill presses are only designed for drilling through soft metals like aluminum or brass. Other drill presses are designed for drilling through harder metals like steel.

Before using a drill press on any metal, make sure to consult the owner’s manual to ensure that the machine is compatible with the type of metal you intend to use it on. Failure to do so could result in damage to the drill press or injury to yourself.

Is there a difference between a wood and metal drill press?

Yes, there is a difference between a wood and metal drill press. A metal drill press is designed for drilling holes in metal, while a wood drill press is designed for drilling holes in wood. Metal drill presses are usually more powerful than wood drill presses and have different features that make them better suited for drilling through metal.

For example, most metal drill presses have a built-in coolant system that helps to keep the drill bit cool while it’s being used. This feature is not typically found on wood drill presses.

Useful Video: Jet JDP 17 Drill Press Review

Conclusions

Now that you have read this buyer’s guide, you should have a better understanding of what to look for when shopping for a drill press for metalworking. Keep these factors in mind and you will be sure to find the perfect model for your needs. Thanks for reading, we hope you enjoyed this article. Until next time!

References:

- https://vitalhandtools.com/best-drill-press-for-metal-work/

- https://www.woodworkingsquad.com/drill-press-vs-hand-drill-whats-the-difference/

- https://workshopedia.com/the-history-of-the-drill-press/

- https://www.kingsofwelding.com/buyers-guides/best-drill-press/

- https://houseandbeyond.org/best-drill-press-for-metal/

- https://woodcraftmaniac.com/best-drill-press-for-metal/

- https://applianceanalysts.com/best-drill-presses/