Titanium is arguably one of the most precious metals in the world. Its unique properties make it ideal for applications like aerospace, medical implants, and military equipment. Despite its versatility, titanium ranks among the most challenging metals to produce. From the high cost of extraction to the stringent quality standards, there are several obstacles to overcome in the production process. In this blog post, we’re going to dive deep into why titanium is so hard to produce.

Physical phenomena of titanium processing

There is no denying that titanium is a material that has revolutionized various industries, from aviation to medicine. However, creating titanium products requires a deep understanding of these phenomena that occur during processing.

One of the fundamental phenomena is its deformation behavior, which refers to its response to mechanical forces. Titanium exhibits low modulus of elasticity, meaning that it is more elastic than other metals. It also has low thermal conductivity and high coefficient of thermal expansion, which contribute to its unique deformation characteristics. At high temperatures, titanium becomes more ductile and less prone to cracking, while at low temperatures, it becomes more brittle and susceptible to cracking. Therefore, controlling the temperature and strain rate during forming processes such as forging and rolling is critical to ensure the desired microstructure and mechanical properties. [2]

Heat treatment is another crucial step in titanium processing, which involves heating the material to a specific temperature and holding it for a certain time to achieve the desired microstructure and properties. Finally, titanium processing also involves reactions with other materials, which can affect its surface properties and corrosion resistance. For example, when titanium is exposed to oxygen or nitrogen at high temperatures, it forms a hard, wear-resistant oxide or nitride layer, respectively. This layer, called a “scale,” protects the underlying material from further oxidation or corrosion. Similarly, when titanium is coated with other materials such as ceramics or polymers, it can achieve even greater wear and corrosion resistance. Therefore, understanding the chemistry of titanium reactions with other materials is important for maximizing its performance and longevity. [2]

The phenomena of titanium processing are fascinating and complex. By mastering these phenomena, manufacturers can create titanium products that are strong, lightweight, corrosion-resistant, and biocompatible.

Types of titanium alloys

Titanium is a kind of metal which is widely used in a big number of different industries, such as sports equipment construction, aerospace and even medical implants. But because of the fact that pure titanium is a very soft material, it is often alloyed with other metals. These alloys are known for their ability to resist corrosion, also for their toughness and strength. Below you can see some examples of them. [4]

Alpha Alloys

They are known for their excellent forming and welding ability. These types of alloys contain only alpha-phase crystals. Their properties include high ductility, high toughness, and excellent creep resistance. Moreover, these materials exhibit superior oxidation resistance. Examples of this kind of alloys are Ti-6Al-2Sn-4Zr-2Mo and Ti-5Al-2.5Sn.

Alpha-Beta Alloys

These alloys are a combination of alpha-phase and beta-phase crystals. These alloys possess a good balance of strength, toughness, and workability. They are the most common titanium alloys and they are really popular in the aerospace and medical industries. Examples of alpha-beta alloys are Ti-6Al-4V and Ti-10V-2Fe-3Al .

Beta Alloys

They contain only beta-phase crystals and are known for their high strength and excellent machinability. However, they are susceptible to corrosion and are difficult to weld. Beta alloys, like alpha-beta ones, are also prone to creep deformation at high temperatures. Examples of beta alloys are Ti-15V-3Cr-3Al-3Sn and Ti-3Al-8V-6Cr-4Zr-4Mo.

Osteoconductive Alloys

These alloys have biocompatible properties that make them ideal for creating artificial joints and implants. Osteoconductive alloys contain calcium phosphate, which helps promote bone growth. Examples of osteoconductive alloys are Ti-13Nb-13Zr and Ti-6Al-7Nb.

Shape Memory Alloys

These alloys can remember their original shape and return to it after undergoing deformation. This makes them useful in industries like aerospace and automotive, where self-healing materials can prolong the life of components. Examples of shape memory alloys are Ti-50.8Ni-49.2Co and Ti-50.2Ni-29.8Cu-20.0Cr.

Benefits and Drawbacks of Using Titanium

Titanium is a strong, lightweight metal that has become increasingly popular for a variety of uses. However, before deciding to use titanium for your personal or professional project, it is important to consider the benefits and drawbacks.

Benefits of Using Titanium

Durability: Titanium is incredibly durable and offers a longer lifespan than most other metals. For this reason, it is widely used in the production of high-impact sporting equipment, such as golf clubs and tennis rackets.

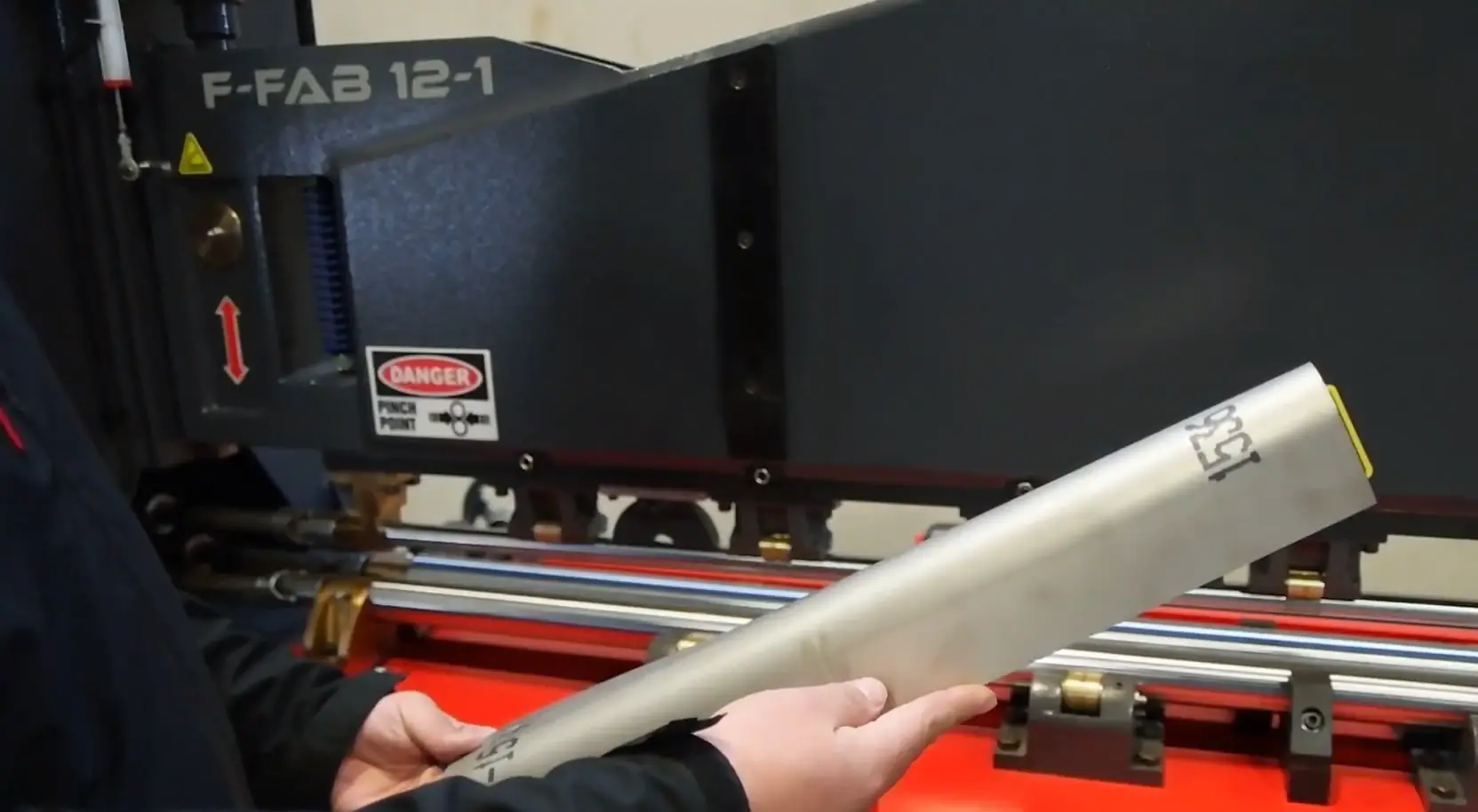

Lightweight: Titanium is the ultimate lightweight metal, making it the perfect metal for anything that requires strength without weighing much. By the way, it is 45 percent lighter than steel. [1]

Corrosion Resistance: Titanium is highly corrosion-resistant, meaning it can withstand harsh environments without rusting or corroding.

Bio-compatibility: it is biologically compatible with the human body, which makes it a popular metal for medical implants. Additionally, it doesn’t contain any harmful substances, which makes it safe to use over long periods of time.

Drawbacks of Using Titanium

Higher Cost: One of the major drawbacks of using titanium is the cost. Titanium is a relatively expensive metal to produce, which can make it challenging to justify using it in smaller scale applications.

Difficult to Fabricate: Titanium is difficult to manufacture and work with, requiring expensive and specialized tools to shape into the desired form.

Risk of Fracture: While titanium is incredibly strong, there is also a risk of fracture if it is not treated properly. This is particularly true if the metal has been exposed to extreme temperatures or mechanical stress.

Limited Color Options: Unlike other metals like steel, brass, and bronze, titanium is less versatile when it comes to coloring. It is naturally gray, and although it can be polished to create different shades, it still has limited options for customizing its appearance.

While there are advantages and disadvantages to using titanium, it ultimately boils down to the specific needs and requirements of your project.

What Makes Titanium Difficult to Machine?

As a material, titanium has earned a reputation for its exceptional performance. However, while its properties make it an ideal choice, it is also notoriously difficult to machine.

One of the main reasons titanium is difficult to machine is the high strength-to-weight ratio. It means that titanium is strong and lightweight, which is ideal for aerospace components and medical implants. However, machining a strong material requires more force which puts more stress on the machines.

Another challenge with machining titanium is its reactive properties. When exposed to oxygen, titanium oxidizes, forming a hard, protective layer on the surface. This layer is resistant to corrosion, which makes titanium an excellent choice for implants and structures exposed to harsh environments. However, during the machining process, heat and friction generated can cause the protective oxide layer to break down, leading to further oxidation. This can cause a sudden, uncontrolled reaction known as “thermal runaway,” which can damage the material and the machining tools.

Unlike other metals that deform or break when subjected to pressure, titanium has a high level of elasticity. This makes it difficult to achieve the required tolerances during machining, as the material tends to spring back to its original shape.

Finally, titanium has a low thermal conductivity, which means that it doesn’t conduct heat very well. This can cause heat to build up during machining. High-speed machining can create too much heat, causing deformations and melting. Therefore, it is important to control the temperature during the machining process to prevent it from becoming too hot.

Understanding the unique properties of titanium is crucial in achieving the required tolerances and preserving the material’s integrity during the machining process.

Tools for Cutting Titanium

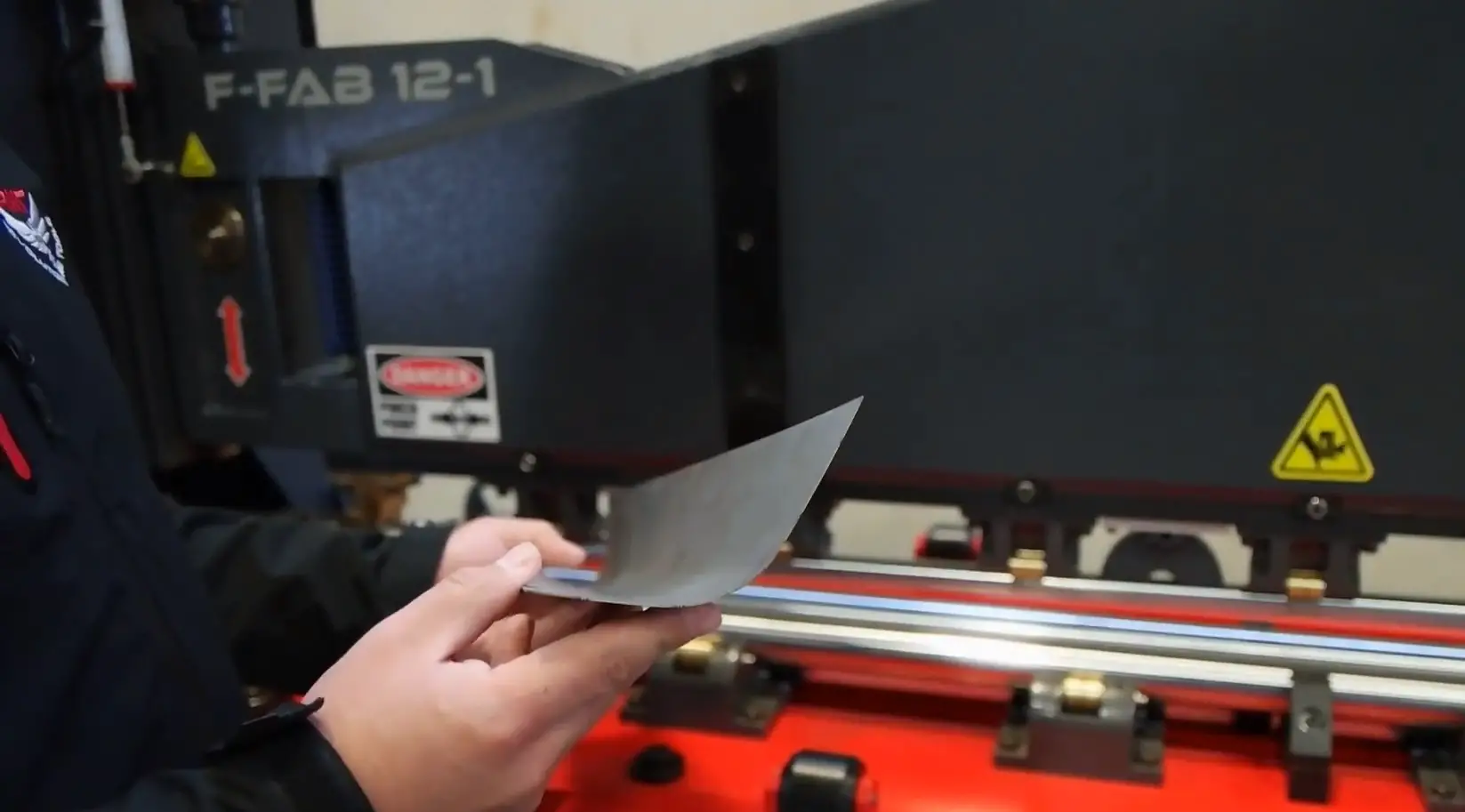

Cutting titanium can be a challenging task since it is a hard metal and can wear down cutting tools quickly. It’s essential to use the right tools and techniques when cutting titanium to prevent damage to the equipment and ensure accurate cuts.

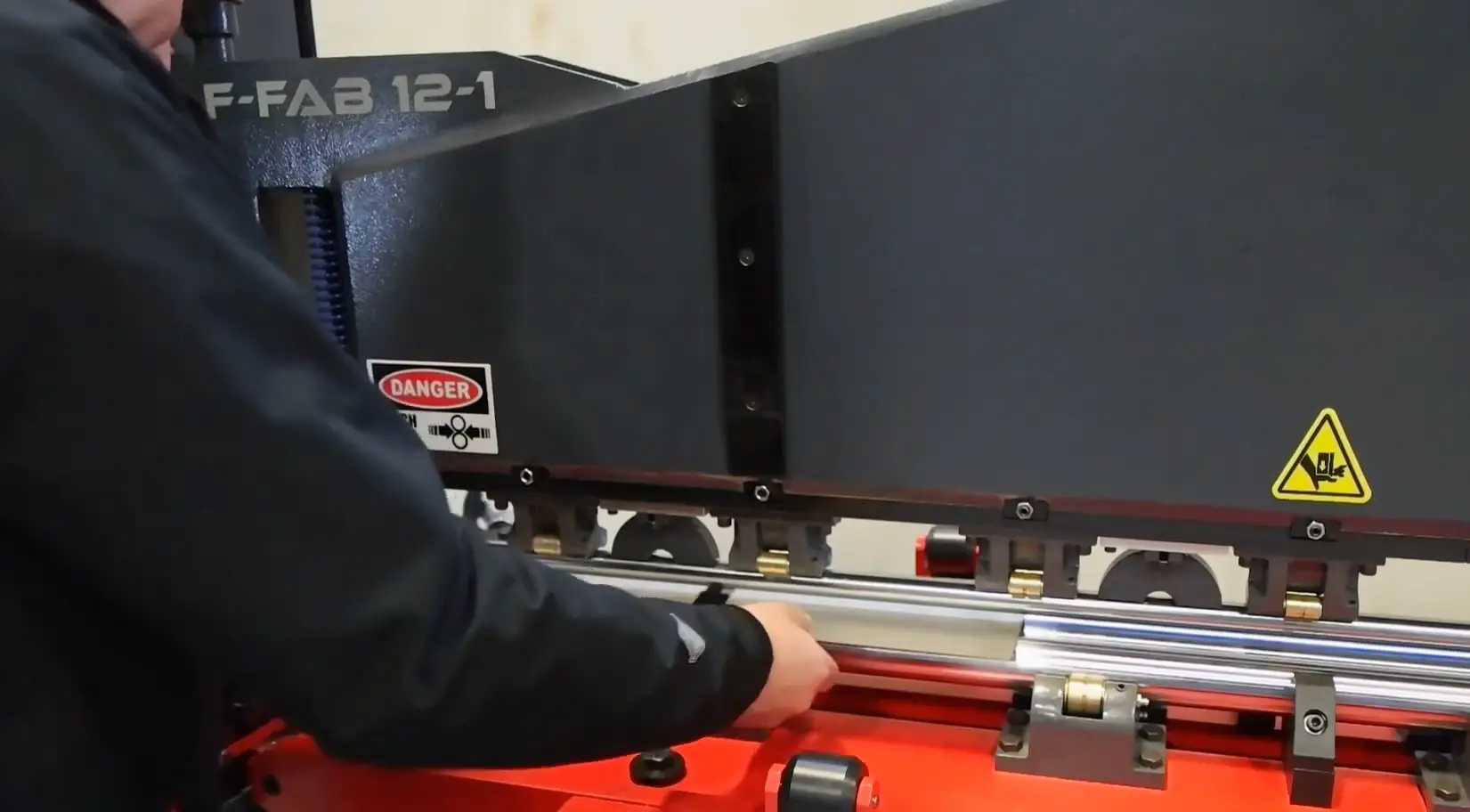

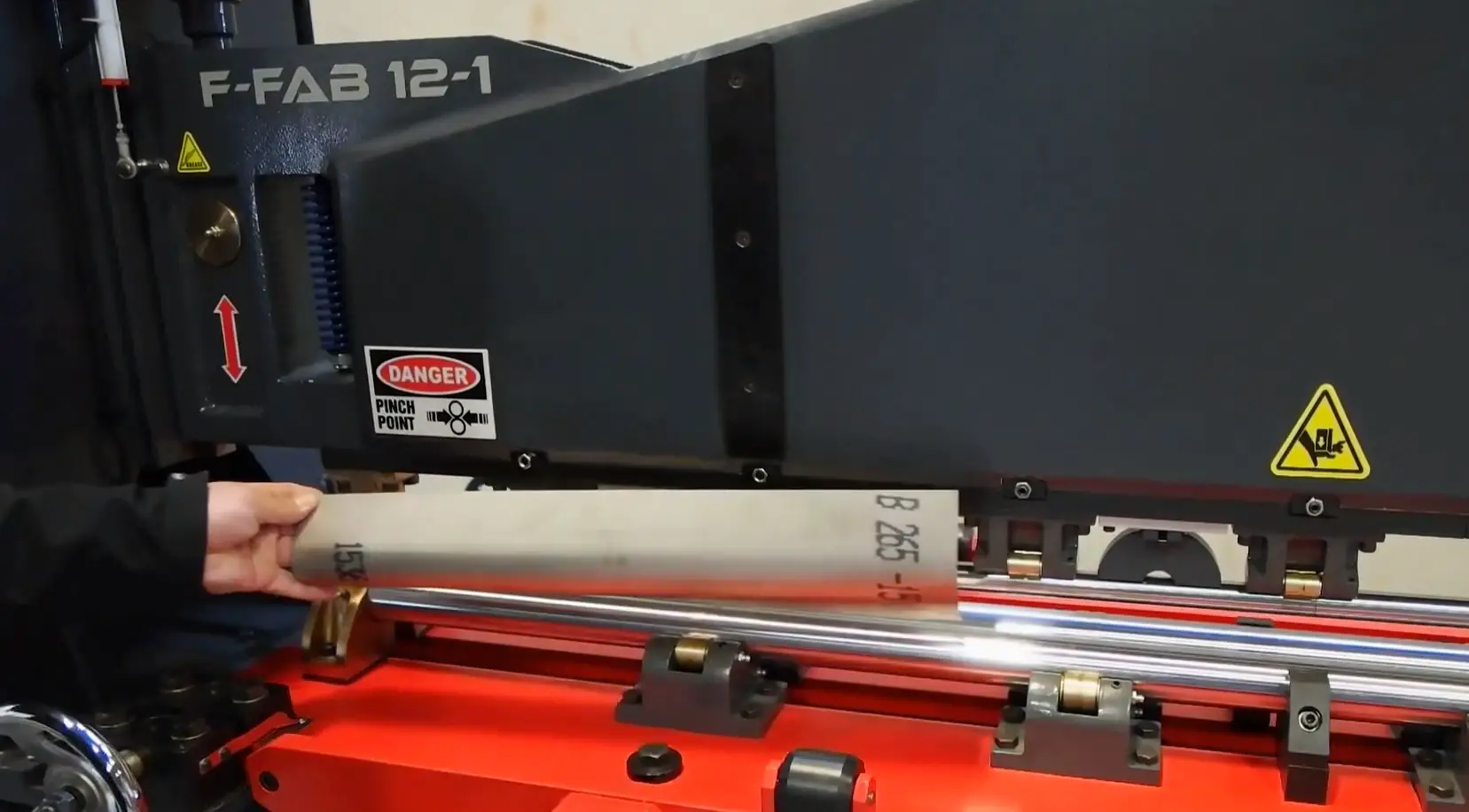

Carbide tools are an excellent choice for cutting titanium since they are harder and more wear-resistant than high-speed steel tools. These tools are made of a combination of tungsten carbide and cobalt, which makes them durable and long-lasting. [3]

Diamond tools are another option for cutting titanium since diamonds are not only the hardest, but they also resist heat better than other materials. A diamond tool can cut through titanium like butter and leave a clean, smooth cut. Diamond tools are suitable for high-speed cutting and are primarily used for turning or boring holes in titanium. However, diamond tools are costly and should be used only on a large scale when the cost is justified.

Plasma arc cutting is also a widely used method for cutting titanium. The process involves using a plasma torch to generate a high-temperature plasma stream that melts the metal, making it easy to cut. It is faster than waterjet cutting and can cut through thicker materials. The downside of plasma cutting is that it produces a lot of heat, which can cause thermal distortion and leave a rough edge.

Laser cutting is the most precise and accurate cutting method when it comes to cutting titanium. It uses a high-energy laser beam to melt the metal and create precise cuts with minimal distortion. Laser cutting is ideal for making intricate cuts, and it’s a clean process that doesn’t require any additional finishing.

Cutting titanium requires the right tools and techniques to ensure that you achieve precise and accurate cuts while reducing the risk of damage to the tools.

FAQ

Is titanium difficult to manufacture?

Its manufacturing process can be challenging and costly, making it one of the most expensive metals on the market. [3]

Why is titanium so expensive to manufacture?

Titanium is expensive because of the complexity of its production. It’s hard to extract from its ore, ilmenite- a process that involves high temperatures and electrical voltages that can run up the cost. Titanium is highly reactive with most other elements, which means processing it requires extreme care and often involves complex vacuum systems. Finally, the machinery and equipment required for titanium extraction and processing is also expensive, requiring specialized equipment and a skilled workforce.

Is titanium harder to machine than steel?

Yes, titanium is harder to cut than steel. While its high strength is useful for specific applications, it can be a drawback when manufacturing. It can rapidly blunt conventional cutting tools, resulting in decreased machining speeds and a higher risk of equipment damage. Therefore, machining titanium requires specialized tools and techniques that increase production times and costs.

Why is titanium harder than gold?

Titanium owes its hardness to its high strength-to-weight ratio and its ability to form strong intermetallic compounds.

Why is titanium not more commonly used?

The high cost of titanium, coupled with the difficulty of its manufacturing and the specialized equipment required, has hindered its broader adoption. Most traditional industries prefer cheaper metals such as steel and aluminum because they can perform similarly at a lower cost.

Useful Video: How Difficult is Titanium to Form? | RMT Aircraft Roll

Conclusions

Titanium may be a valuable and desirable metal, but its production is not without challenges. The high melting point, reactive properties, complex extraction process, expensive equipment, and strict quality control measures required all contribute to making titanium a difficult metal to produce. Despite these challenges, the demand for titanium is projected to increase in the coming years as it continues to find new applications in a variety of industries. As such, the development of new technologies and production methods for titanium will be an important area of research and development in the years to come.

References:

- https://aaluminum.com/blog/why-is-titanium-so-hard-to-produce/

- https://www.linkedin.com/pulse/why-titanium-alloy-difficult-process-irene-qiang

- https://blogs.autodesk.com/advanced-manufacturing/2018/08/25/is-it-really-that-hard-to-machine-titanium/

- https://www.ukocarbide.com/blog/why-is-titanium-alloy-a-difficult-to-process-material/